Why powder coating has good wear resistance?

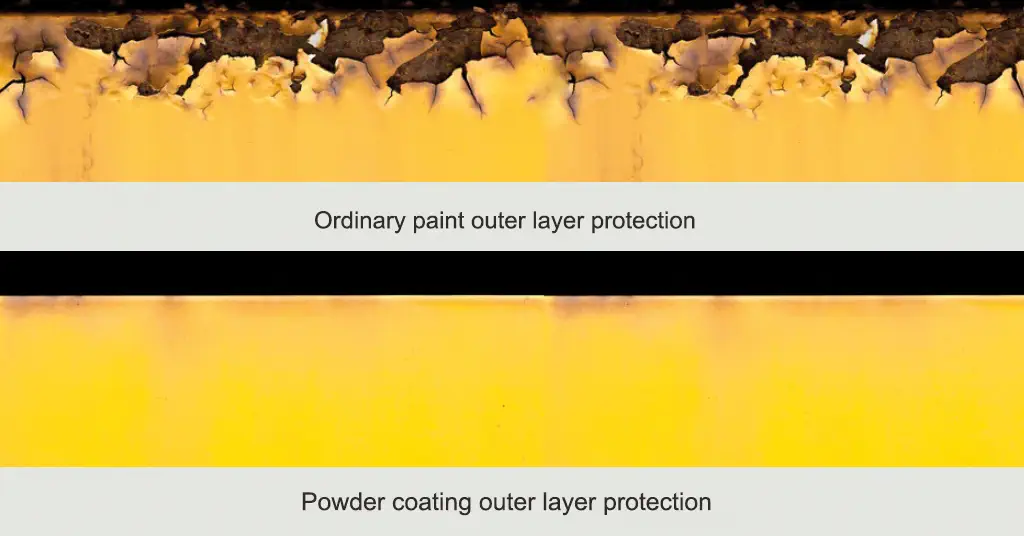

When talking about the protective and wear-resistant properties of object surfaces, powder coatings are a topic that attracts much attention. Powder coatings play an important role in industry, construction, automobiles, home appliances and other fields. Its excellent wear resistance often makes it the first choice for protective outer coatings. So, why does powder coating have such superior wear resistance? Let’s explore the mysteries together!

1. Why does powder coating have good wear resistance?

The excellent wear resistance of powder coatings is mainly due to its composition and characteristics. The material hardness, uniform coating, chemical stability, strong adhesion and weather resistance of powder coatings together constitute the good wear resistance of powder coatings

a. Material hardness

The raw materials of powder coatings are usually composed of hard resins, pigments, curing agents and additives. These materials inherently have high hardness. After melting and solidifying, the surface layer of the powder coating will form a strong coating that can effectively resist wear and tear due to external forces.

b. Even coverage

When using spray paint for electrostatic spraying, the negative charges in the powder coating are strongly attracted to the positive charges on the workpiece. Therefore, the entire tool to be sprayed will be evenly covered by the powder coating. Since each position of the entire workpiece has the same powder coating thickness, there will be no local weak areas, thereby improving the overall wear resistance.

c. Chemical stability

The raw materials and additives in powder coatings basically have good chemical stability. Under normal circumstances, it will not actively react with other substances. In particular, the outer layer of the melted and solidified powder coating has a stable protective film, which prevents corrosion by chemical substances. Certain ceramic particles or polymer particles may also be added to some specific powder coatings. These additives will also increase the hardness and wear resistance of the powder coating.

d. Strong adhesion

After the powder coating melts and solidifies, chemical bonding occurs between the coating and the substrate, forming a strong connection. The resin component in the powder coating reacts with the metal in the substrate to covalently bond. The metal ions in the powder coating ionically bond with the oxygen ions in the substrate. The hydrogen atoms in the powder coating hydrogen bond with the oxygen atoms in the substrate. Strong adhesion allows powder coatings to perform well against ordinary scratches.

2. What are the methods to improve the wear resistance of powder coatings?

a. Choose powder coatings with strong wear resistance

Choose powder coatings with high hardness and high wear resistance, such as coatings containing ceramic or polymer particles, which can enhance the wear resistance of the coating.

b. Use proper pre-treatment and primer

Proper surface pre-treatment and primer can provide better adhesion, thereby enhancing the abrasion resistance of the coating. For example, using a rust-inhibiting primer can prevent corrosion on metal surfaces, thereby increasing the durability of the coating.

c. Increase the coating thickness:

Increasing the coating thickness of powder coating can improve the wear resistance of the coating. However, be careful not to increase the coating thickness so much that it affects the appearance and performance of the coating.

d. Add anti-wear agents

Adding anti-wear agents, such as silicone, polyethylene or polytetrafluoroethylene particles, to powder coatings can improve the wear resistance of the coating.

e. Increase the baking temperature and time

Increasing the temperature and/or extending the baking time during the baking process can promote the cross-linking and hardening of the coating, thereby improving wear resistance.

f. Surface lubricant

After coating, a surface lubricant or coating sealer can be applied to increase the wear resistance of the coating and reduce friction.

g. Use wear-resistant coating technology

Some special coating technologies, such as wear composite coatings or ceramic coatings, can provide excellent wear resistance and are suitable for highly wear-resistant applications

In this article, we take a closer look at why powder coatings have good abrasion resistance. We also explore the key factors in developing abrasion resistance in powder coatings and how to improve the abrasion resistance of powder coatings. . The wear-resistant properties of powder coatings make them the first choice for many industries, and the future possibilities are exciting. Therefore, understanding and utilizing the wear-resistant properties of powder coatings will provide products and projects with lasting value and superior performance, whether in automotive manufacturing, construction or elsewhere. If you encounter any problems in the field of powder coating, please feel free to contact us. UCOAT has decades of professional experience in the field of powder coating R&D and production. We are happy to provide you with free powder coating solutions.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?