Application of powder coating in construction field

powder coating for Construction

steel structure

metal doors and windows

Exterior wall panels

Roof system

Railings and Handrails

Solar panel bracket

drainage system

Building components and accessories

Types of powder coating for Construction

If you need a special type of powder coating or would like to customize a powder coating in a different RAL color, please contact us right now!

AAMA Specification for Architectural Coatings Performance

The use of powder coatings in the construction sector often requires the development of durable, energy-saving, low-maintenance solutions. The durability, long-term luster and long-term corrosion resistance of metal substrates are critical to architectural finishes. The American Architectural Manufacturing Association (AAMA) has developed a rigorous set of testing standards and specifications for coatings in the architectural field.

| Specification | AAMA 2605 | AAMA 2604 | AAMA 2603 |

| Color Retention | 10 yrs: Fade = 5 Delta E | 5 yrs: Fade = 5 Delta E | 1 year: "slight" fade |

| Chalk Resistance | 10 yrs: Chalk = 8 | 5 yrs: Chalk = 8 | 1 year: "slight" chalk |

| Gloss Retention | 10 yrs: 50% retention | 5 yrs: 30% retention | No specification |

| No specification | 10 yrs: 10% loss | 5 yrs: 10% loss | No specification |

| Dry Film Thickness | 1.2 mils minimum | 1.2 mils minimum | 0.8 mils minimum |

| PRETREATMENT SYSTEM: | CHROME OR CHROME FREE | CHROME OR CHROME FREE | CHROME OR CHROME FREE |

| Salt Spray | 4,000 hours | 3,000 hours | 1,500 hours |

| Humidity | 4,000 hours | 3,000 hours | 1,500 hours |

| Warranty | 10 Year | 5 Years | 1 Year |

Coatings should be visibly free from flow lines, streaks, blisters or other surface imperfections in the dry-film state on exposed surfaces when observed at a distance of 10 feet (3 m) from the metal surface and inspected at an angle of 90 degrees to the surface.

AAMA 2605 is the highest standard for superior performing organic coatings on architectural aluminum extrusions and panels. These coatings demonstrate exceptional resistance to colour fading, chalking, gloss loss, and damage caused by harsh environmental conditions.

Coatings that meet AAMA 2605 are designed for use in severe environmental conditions, high-traffic areas, or for any application where exceptional colour and gloss retention are paramount. They are commonly used on commercial and monumental buildings, or in areas with high UV exposure.

To comply with AAMA 2605, coatings undergo rigorous testing, which includes a minimum of 10 years of outdoor exposure in South Florida or equivalent conditions to evaluate colour retention, gloss retention, and chalk resistance. These high-performing coatings offer the best resistance to weathering and maintain their aesthetic and functional properties over an extended period.

AAMA 2604 is an intermediate standard for high-performance organic coatings applied on architectural aluminum components. These coatings offer enhanced resistance to weathering, chalking, fading, and gloss loss.

Coatings conforming to AAMA 2604 are suitable for high-traffic areas, residential buildings, and locations experiencing moderate environmental conditions. They provide an excellent balance between performance and economy.

Coatings that meet this standard have undergone rigorous tests that include a minimum of five years of outdoor exposure in South Florida or similar conditions to assess colour retention, gloss retention, and chalk resistance. AAMA 2604 coatings provide good weather resistance and maintain their aesthetic qualities for a more extended period than AAMA 2603 coatings.

AAMA 2603 is the basic standard for powder and liquid coatings on aluminum used in interiors and mild exterior environments. This standard covers the evaluation of coating performance through tests for colour retention, chalk resistance, and gloss retention.

AAMA 2603 coatings are typically applied to aluminum components used in environments with limited exposure to harsh weather elements and chemicals. This includes interior applications and select exterior applications with mild environmental conditions.

The standard calls for a minimum of one year of outdoor exposure in South Florida or comparable conditions to test for gloss retention, colour retention, and chalk resistance. While the performance of AAMA 2603 coatings may vary, they generally offer less resistance to weathering compared to the higher standards.

Precautions for the application of powder coatings in the construction field

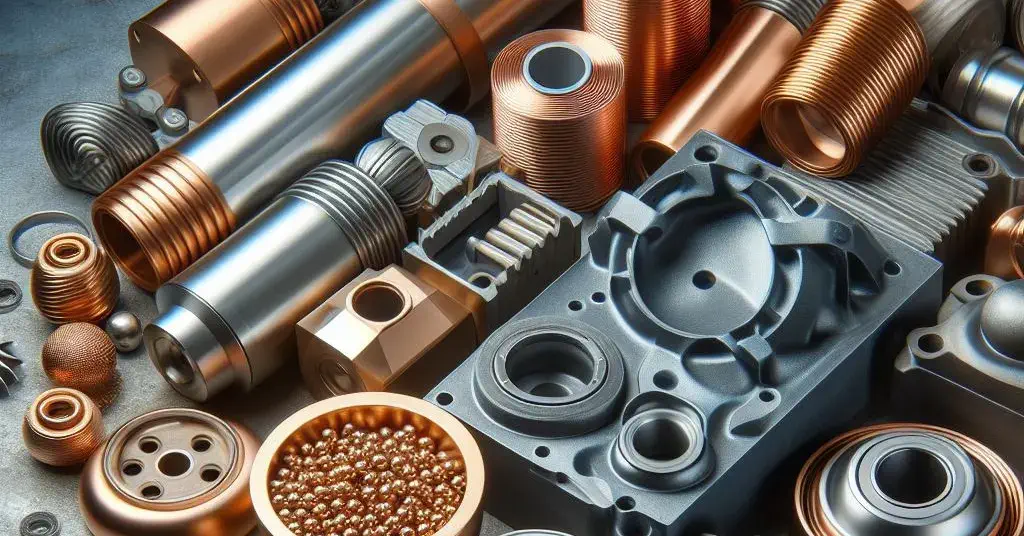

a. Choose the correct powder coating according to the type of building material

- Steel: Steel has good strength and stiffness, but is prone to rust. Commonly used powder coatings include epoxy powder coatings, polyester powder coatings, etc.

- Aluminum: Aluminum has good corrosion resistance and thermal conductivity, but is prone to oxidation. Commonly used powder coatings include fluorocarbon powder coatings, acrylic powder coatings, etc.

- Concrete: Concrete has good wear resistance and strength, but is prone to absorbing water. Commonly used powder coatings include polyester powder coatings, acrylic powder coatings, etc.

- Wood: Wood has good decorative and thermal insulation properties, but is prone to corrosion and discoloration. Commonly used powder coatings include polyester powder coatings, epoxy powder coatings, etc.

b. Pretreatment of building materials

When using powder coatings in the construction field, pretreatment of the substrate is an important part of powder coating construction. The base material should be clean and dry, free of oil, rust, etc. to ensure the adhesion of the powder coating.

Specifically, the substrate processing steps are as follows:

- Cleaning: Remove all dirt, oil, rust and other debris on the surface of the substrate. You can use high-pressure water guns, wire brushes and other tools for cleaning.

- Rust removal: For rusty base materials, special rust remover or sandblasting should be used to remove rust.

- Sanding: For smooth substrates, sandpaper should be used for sanding to increase the surface roughness of the substrate.

- Dust removal: Use a vacuum cleaner or compressed air to remove dust and debris from the surface of the substrate

c. Safety protection when using powder coatings

Powder coatings are flammable and explosive materials, so safety precautions should be taken when using them in the construction field. Here are some safety precautions:

- Have a well-ventilated workplace: Powder coatings release harmful gases during the curing process, so the workplace should be well-ventilated.

- Wear protective equipment: During the powder coating spraying process, you should wear protective equipment such as gas masks, gloves, and goggles to prevent powder coating from entering the respiratory tract, skin, and eyes.

- Keep away from fire sources: Powder coatings are flammable and explosive and should be kept away from fire sources.

- Pay attention to storage and transportation: powder coatings should be stored in a cool, well-ventilated place and pay attention to fire prevention

Have Anything To Ask Us?