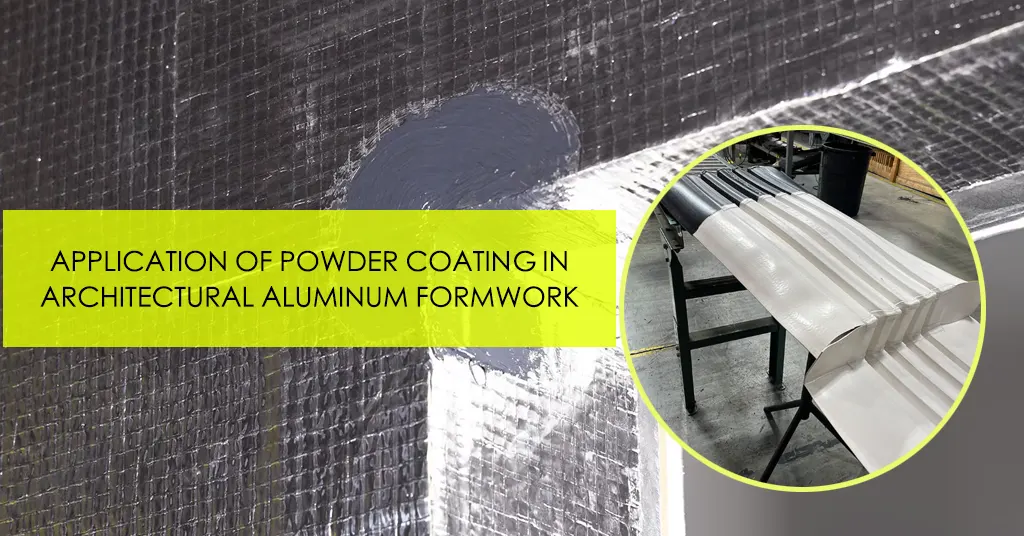

Application of powder coating in industry field

powder coating for industry

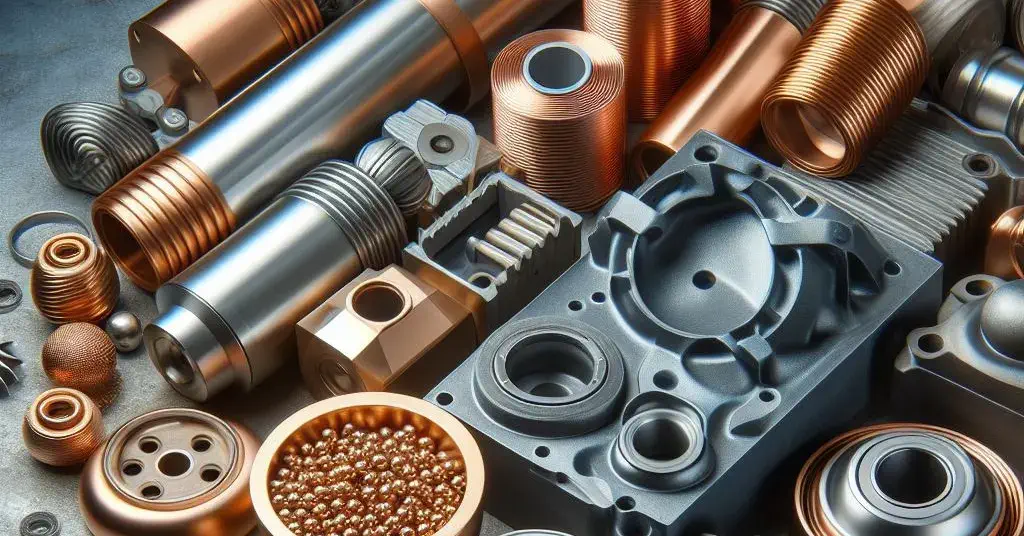

Chemical pipeline

oil storage tank

Industrial valve

Industrial cable tower

Industrial Cooling Tower

Industrial conveyor belt

wind turbine

Industrial heat exchanger

Types of powder coating for industry field

If you need a special type of powder coating or would like to customize a powder coating in a different RAL color, please contact us right now!

Powder coating colors available for industrial use

We have many different colors of powder coatings available for you to choose from for the industry sector. The above colors are part of our existing powder coatings and can be shipped immediately if you need them. If you have special powder coating color customization requirements, please inform us of the specific RAL color card number or Pantone color number.

FAQs About Powder Coating in Industry Field

Powder coating is different from liquid coating in that it is a powdered solid that does not contain volatile organic compounds (VOCs), so it is environmentally friendly and does not require solvents.

Powder coating has the advantages of corrosion resistance, wear resistance, environmental protection, good weather resistance, and high coating efficiency, so it is widely used in the industrial field.

Powder coatings are used in various industrial sectors including automotive, electronics, construction, aerospace, chemicals, manufacturing, metal processing, oil and gas, food processing, and more.

Powder coatings are available in a variety of colors and surface effects, including smooth, textured, metallic, orange peel, and more.

Cleaning, degreasing, rust removal and surface treatment are usually required to ensure that the surface of the workpiece is clean, flat and adherent.

The coating process includes steps such as pretreatment, charging, spraying, baking and curing to ensure uniformity and durability of the coating

The cure temperature of powder coatings depends on the material and formulation, but is typically between 350°F (177°C) and 450°F (232°C).

Cure time depends on the material and process, but is usually between 15 minutes and 30 minutes.t

Have Anything To Ask Us?