Why is epoxy powder coating the first choice for home appliance housings?

What is epoxy powder coating?

1. Excellent corrosion resistance

2. Excellent mechanical properties

3. Good adhesion

Epoxy powder coating forms chemical bonds with metal substrates during the curing process, and has extremely strong adhesion. This means that the coating is not easy to peel or bubble, and it can remain stable even under extreme conditions (such as high temperature and high humidity environments). This feature is particularly important for home appliance housings because it ensures the long-term reliability of the coating in complex use environments.

4. Beautiful and diverse appearance

5. Environmental protection and cost-effectiveness

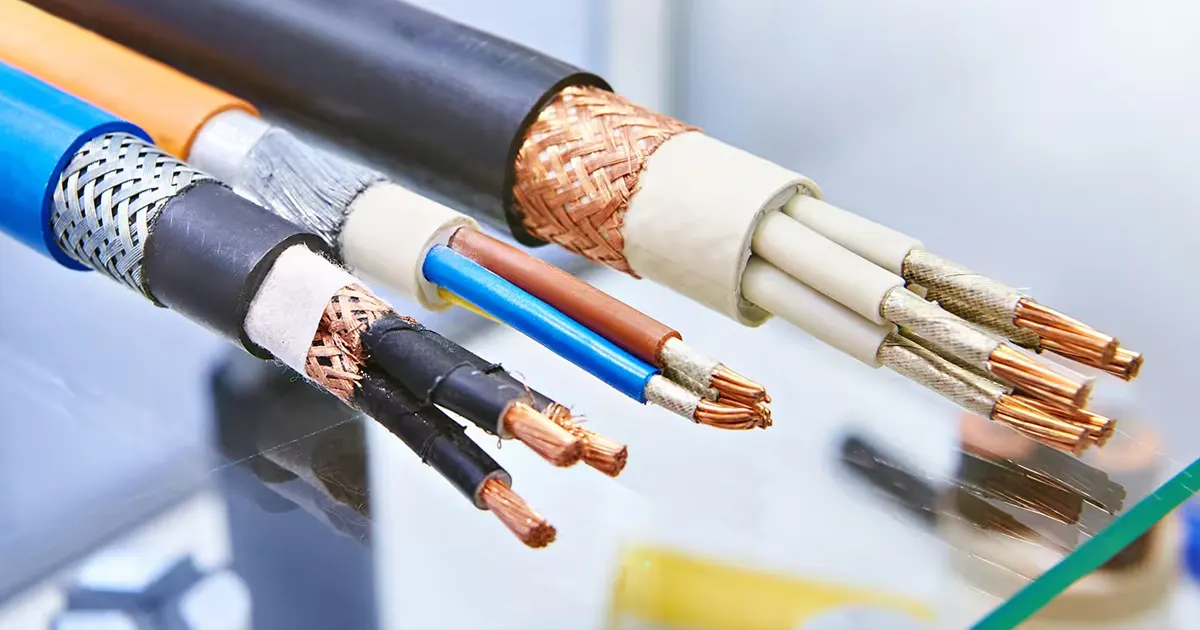

Practical Application of Epoxy Powder Coatings in Appliance Housings

In practical applications, epoxy powder coatings are widely used for coating the housings of various home appliances. For example:

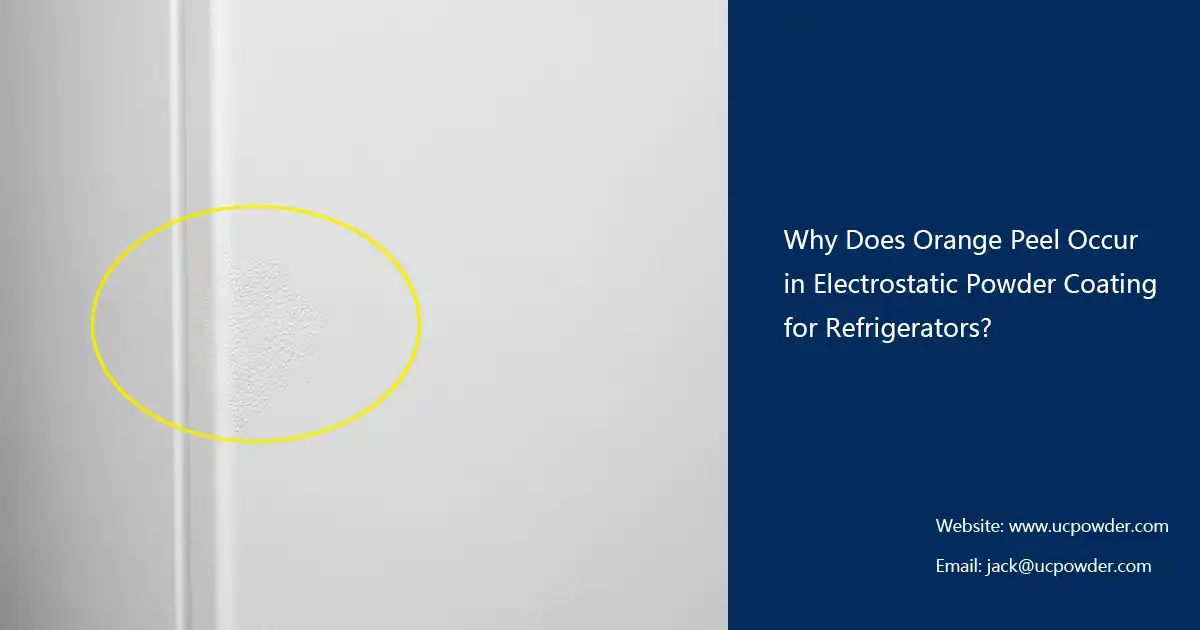

Refrigerators and freezers

The refrigerator housing needs to withstand the humid environment and frequent use of detergents in the kitchen. The corrosion resistance and easy cleaning properties of epoxy powder coatings make it an ideal choice.

Washing machines and dryers

These home appliances are often in high humidity environments. The anti-rust properties of epoxy powder coatings ensure long-term durability of the housing.

Microwave ovens and ovens

Epoxy powder coatings can withstand thermal stress in high temperature environments while maintaining the gloss and color stability of the coating.

In addition, epoxy powder coatings can be mixed with other coatings (such as polyester powder coatings) to form composite coatings to further enhance specific properties, such as weather resistance or UV resistance, to meet the special needs of different home appliances.

How to choose the right epoxy powder coating?

Identify the use environment

Determine the chemical and physical challenges that the appliance housing will face, such as whether higher heat resistance or UV resistance is required.Choose the right color and surface effect

Communicate with the design team to ensure that the appearance of the coating meets the brand image and market needs.Consider the coating process

Make sure the spray equipment and curing ovens on the production line can meet the process requirements of epoxy powder coatings, such as curing temperature (usually 180-200°C) and time.Work with suppliers

Choose experienced coating suppliers who can provide technical support and customized solutions to ensure that the coating performs as expected.Limitations and countermeasures of epoxy powder coatings

In addition, the curing process of epoxy powder coatings requires higher temperatures, which may limit some heat-sensitive substrates (such as plastics). In this case, manufacturers can consider low-temperature curing epoxy powder coatings to broaden the scope of application.

Conclusion

Have Anything To Ask Us?