Why Epoxy Powder Coating is the Best Choice for Durable Metal Finishes?

When it comes to protecting and enhancing metal surfaces, epoxy powder coating stands out as a superior solution. Known for its durability, versatility, and eco-friendliness, this finishing method has become the go-to choice for industries ranging from automotive to architecture. In this article, we’ll explore why epoxy powder coating is the best option for durable metal finishes and how it can meet your specific needs.

1. What Makes Epoxy Powder Coating Unique?

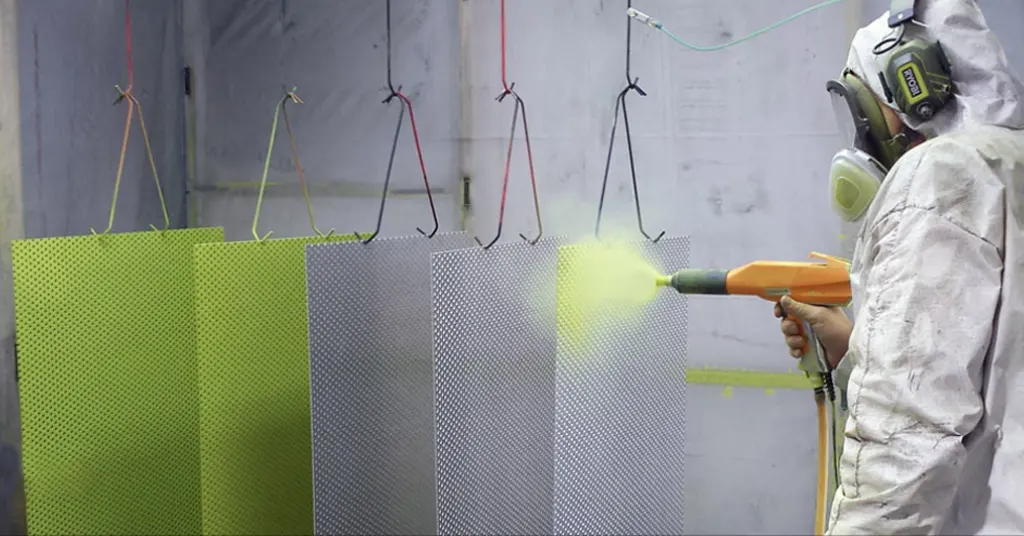

Epoxy powder coating is a dry finishing process that involves applying electrostatically charged powder to a metal surface. The coated object is then cured under heat, forming a hard, protective layer. Unlike traditional liquid paints, epoxy powder coating doesn’t rely on solvents, making it a cleaner and more sustainable option.

2. Key Benefits of Epoxy Powder Coating for Metal Finishes

a. Exceptional Durability

Epoxy powder coating creates a tough, resilient finish that can withstand harsh conditions. It resists chipping, scratching, and abrasion, making it ideal for metal surfaces exposed to heavy use or extreme environments.

b. Superior Corrosion Resistance

Metal surfaces are prone to rust and corrosion, especially in humid or industrial settings. Epoxy powder coating provides a seamless barrier that protects against moisture, chemicals, and other corrosive elements.

c. Eco-Friendly and Safe

With no solvents or harmful VOCs (volatile organic compounds), epoxy powder coating is an environmentally friendly choice. It reduces waste and minimizes health risks for workers during application.

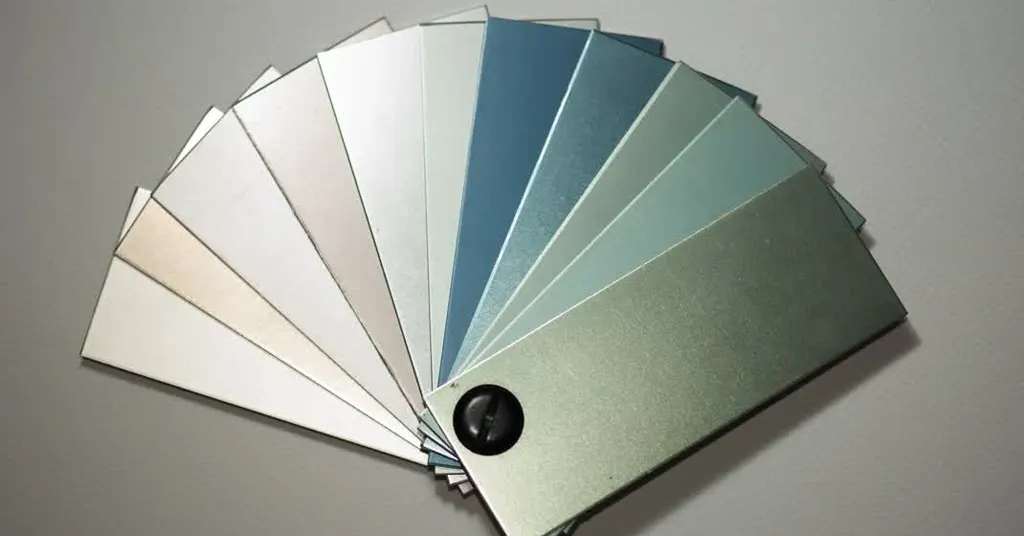

d. Aesthetic Versatility

Available in a wide range of colors, textures, and finishes, epoxy powder coating allows for customization. Whether you want a glossy, matte, or textured look, this method delivers a consistent and attractive finish.

e. Cost-Effectiveness

The efficiency of the application process reduces material waste, and the long-lasting durability of the coating means fewer maintenance costs over time. This makes it a cost-effective solution for both small and large-scale projects.

Epoxy powder coating is widely used across industries due to its versatility and performance. Here are some common applications:

Automotive Industry

From car wheels to engine components, epoxy powder coating protects metal parts from wear, corrosion, and extreme temperatures.

Architecture and Construction

Metal fixtures, railings, and structural elements benefit from the durability and weather resistance of epoxy powder coating.

Industrial Machinery

Heavy-duty equipment and tools are often coated with epoxy powder to withstand abrasion, chemicals, and harsh operating conditions.

Outdoor Furniture

Metal furniture exposed to the elements requires a finish that can resist rust and UV damage. Epoxy powder coating provides both protection and aesthetic appeal.

Electronics and Appliances

Metal casings for electronics and household appliances are often coated with epoxy powder to ensure durability and a polished appearance.

4. Why Choose Epoxy Powder Coating Over Other Finishes?

- Longer Lifespan: Compared to traditional paints, epoxy powder coating lasts significantly longer. Its resistance to wear and tear ensures that metal surfaces remain protected for years.

- Better Adhesion: The electrostatic application process ensures that the powder adheres evenly to the metal surface, creating a uniform finish without drips or bubbles.

- Faster Curing Time: Epoxy powder coating cures quickly under heat, reducing production time and allowing for faster turnaround on projects.

- Low Maintenance: Once applied, epoxy powder coating requires minimal upkeep. Its durability means fewer touch-ups and repairs over time.

How to Achieve the Best Results with Epoxy Powder Coating

a. Proper Surface Preparation

The key to a flawless finish is thorough surface preparation. Clean the metal surface to remove dirt, grease, and rust. Techniques like sandblasting or chemical treatments can ensure optimal adhesion.

b. Choose the Right Powder

Select an epoxy powder formula that matches your project’s requirements. For example, choose a high-temperature powder for automotive parts or a UV-resistant powder for outdoor applications.

c. Control the Application Environment

Apply the powder in a clean, dry, and dust-free environment to avoid imperfections. Proper ventilation and electrostatic equipment are essential for even coverage.

d. Follow Curing Guidelines

Adhere to the manufacturer’s recommended curing temperature and time. Over- or under-curing can affect the finish’s durability and appearance.

e. Inspect the Finished Product

After curing, inspect the coated surface for consistency, thickness, and adhesion. Address any defects before the coating fully sets.

Real-World Examples of Epoxy Powder Coating Success

- Automotive Wheels: Epoxy powder coating is widely used to protect and enhance the appearance of car wheels, ensuring they withstand road debris and weather conditions.

- Industrial Storage Tanks: Metal tanks used for chemical storage are coated with epoxy powder to prevent corrosion and extend their lifespan.

- Outdoor Playground Equipment: Metal playground structures benefit from the durability and safety of epoxy powder coating, which resists rust and provides a smooth, child-friendly finish.

Conclusion

Epoxy powder coating is the ultimate choice for durable metal finishes, offering unmatched protection, aesthetic appeal, and environmental benefits. Its versatility makes it suitable for a wide range of applications, from automotive parts to outdoor furniture. By choosing epoxy powder coating, you’re investing in a long-lasting, cost-effective solution that keeps metal surfaces looking and performing their best.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Latest news

Have Anything To Ask Us?