What is the difference between powder coating and traditional coating?

Powder coatings and traditional coatings are widely used in various industrial fields, construction fields, home appliances fields and daily life fields. Whether you’re a regular consumer or an industry professional, having a solid understanding of their differences will help you make clear decisions on your specific project. In this article, we will take an in-depth look at the characteristics, advantages and applications of both coating technologies in different fields. UCOAT has decades of professional R&D and production experience in the field of powder coatings and hopes to provide you with detailed information and valuable insights.

1. Characteristics of powder coating

Powder coating is a material for coating surfaces. It is popular in many industries and fields because of its unique environmental protection, durability, wear resistance, anti-corrosion, color diversity and efficient coating process. Below is a detailed description of some of the features of powder coatings.

a. Environmental protection

Powder coatings have attracted much attention due to their environmental friendliness. Unlike traditional liquid coatings, powder coatings do not contain harmful volatile organic compounds (VOCs), which means that no chemicals harmful to the environment and health are released during the coating process. This makes powder coatings ideal for meeting strict environmental standards. For projects that focus on sustainability and the environment, powder coating is an excellent choice.

b. Durability

The durability of powder coating is also a big advantage. Once powder coating is cured, it forms a strong surface that is resistant to daily wear and tear, UV radiation, chemicals and the effects of climate change. This durability makes powder coatings ideal for outdoor products, building structures, automotive parts, and other applications where long-term appearance and performance are required

c. Efficient painting process

The application process of powder coating is relatively efficient. It typically involves electrostatically spraying a powder material onto the surface to be coated, and then applying heat to melt and bond the powder particles to the surface. This process does not require solvent evaporation, so it is not only environmentally friendly, but also improves coating efficiency. Powder coatings can achieve high coverage in a single application, reducing waste and the need for re-coating, thus saving time and resources.

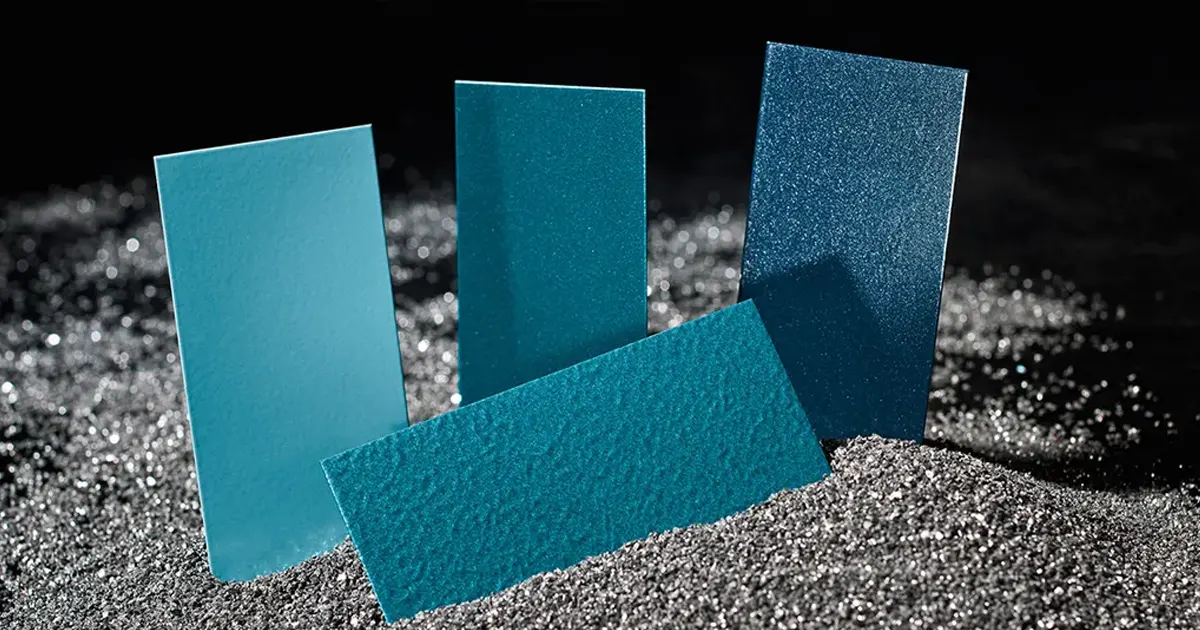

d. Diversity of effects

Powder coatings offer a wide range of color and effect options. It can be applied to a variety of substrates, including metals, plastics and wood, and can achieve a variety of surface effects such as smooth, textured, metallic and matte. This versatility makes powder coating suitable for a variety of different design and decorative needs

2. Characteristics of traditional coatings

Traditional liquid paint is usually applied to the surface of the object in liquid form during the painting process. This type of traditional liquid coating usually contains ingredients such as base material (coating resin), pigments, diluents (volatile organic compounds), additives and auxiliaries. The following are some of the characteristics of traditional paints.

a. Easy to use

Traditional liquid paint is popular for its ease of application. They are usually supplied in liquid form and can be applied quickly to a surface using tools such as brushes, rollers or spray guns. This simple application process makes traditional liquid paint suitable for a variety of projects, from home renovations to large-scale industrial painting.

b. Wide range of uses

Traditional liquid paints are very versatile and can be used on different types of surfaces and materials, including wood, metal, concrete and plastic. This makes traditional liquid coatings widely used in various fields such as construction, automobiles, furniture and art.

c. Easy to adjust paint color

Traditional liquid paints offer excellent color and effect flexibility. They can achieve almost any color and shine level by simply adjusting the formula. This feature is useful for projects that require specific colors or decorative effects, such as interior design and artistic creations

d. Easy to repair

Traditional liquid paints are relatively easy to repair because they can be easily applied over an already painted surface. This is very helpful for surfaces that may have been damaged or worn during use, as only the damaged areas need to be reapplied without the need for a complete replacement.

e. Controllable drying time

The drying time of traditional liquid paint can be controlled as needed. This means that you can choose fast-drying paints on projects that require a quick application, and slow-drying paints on projects that require more time for detailed work. This controllability makes traditional liquid coatings ideal for a variety of time-critical tasks.

3. The difference between powder coating and traditional coating

| Features | powder coating | Traditional liquid paint |

| Environmental protection | Contains no volatile organic compounds | Contains VOCs, which may be harmful to the environment and health |

| Durability | Strong weather resistance, not easy to fade, resistant to chemical corrosion | Easily damaged and requires regular maintenance and painting |

| Painting process | Electrostatic spraying, efficient coating process | Easy to operate and long painting time |

| Applicable fields | Metal, construction, agriculture, chemical industry | Architecture, furniture, art |

| Repair ability | Difficult to repair and requires repainting | Relatively easy and can be partially repaired |

| Application cost | Initial equipment investment is high | Lower overall cost of use |

4. Application areas of powder coatings and traditional coatings

Powder coatings and traditional liquid coatings have different advantages in different industries and fields, so which coating to choose depends on the specific needs and conditions of the project. The following are more applicable areas of different coatings

a. Areas where powder coating is more suitable

- Coating of Large Metal Products and Parts: Powder coatings excel in the painting of large metal products and parts because they can quickly and evenly coat large areas through efficient coating processes such as electrostatic spraying.

- Requires a high degree of durability and weather resistance: For applications that require long-term resistance to external environmental conditions, such as outdoor equipment, automotive parts, and building structures, the weather resistance and durability of powder coatings make them the first choice. They are not prone to fading, peeling or being affected by chemical attack.

- High environmental requirements: If the project needs to meet strict environmental standards, powder coatings are an ideal choice because they do not contain volatile organic compounds (VOCs) and harmful solvents.

- Diverse surface effects are required: Powder coatings offer a variety of surface effects, such as smooth, textured, metallic, and matte, making them ideal for projects that require a different look.

b. Fields where traditional coatings are more suitable

- Small-scale or personal projects: For small-scale projects or personal use, such as home renovations, DIY projects, or art production, traditional liquid paints are easier to obtain and apply.

- Projects that require quick repair: Traditional liquid paint is relatively easy to repair and can be quickly touched up when needed. It is suitable for projects that need to maintain the integrity of the appearance.

- Low-cost budget items: Traditional liquid coatings usually have lower initial equipment and facility investment costs, which allows traditional coatings represented by paint to be produced and used at a cheaper price.

When choosing a coating technology, it is crucial to understand the differences between powder coatings and traditional liquid coatings. Each paint has its own unique characteristics and benefits, and depending on your specific needs, you can choose the one that best suits your project. Whether you are looking for environmental friendliness, weather resistance or cost-efficiency, you can find the right choice between these two coating technologies. I hope this article has been helpful for you to better understand and apply these two coating technologies. If you have any questions or require further advice, please feel free to contact our expert team.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?