What is the baking and curing process of powder coating?

Have you encountered problems such as cracking, blistering, and peeling during the baking and curing process of powder coatings? Are you looking for a stable and reliable powder coating curing solution? In this article, we will introduce the three stages in the powder coating curing process in detail, and inform you about the parameter selection for powder coating curing and related matters that need to be paid attention to during the powder coating curing process. Hope it can provide effective help for your powder coating curing process.

1. What are the three stages of powder coating curing?

a. Aggregation stage

The agglomeration stage is the first stage of baking and curing of powder coatings, and it is also the stage that takes the least time. The entire agglomeration process is usually completed within 1-3 minutes. At this stage, the surface of the powder coating particles begins to melt and form a molten layer due to high temperature baking. As the temperature of the oven gradually increases, the molten layer gradually expands and the surrounding powder coating particles aggregate with each other.

The main influencing factors during the agglomeration stage include the type of powder coating, coating thickness and workpiece size. The thicker the powder coating, the longer the coalescence time required for larger workpieces. The purpose of the agglomeration stage is to form a preliminary bonding layer on the coating surface to lay the foundation for the flow stage and cross-linking curing stage. If the coalescence stage is incomplete, problems such as peeling and peeling of the coating will occur.

b. Flow stage

The flow stage is the second stage of powder coating curing and generally takes 3-10 minutes. At this stage, the powder coating particles have completely melted and started to flow. The flowing powder coating will fill in all uneven areas on the surface of the workpiece to form a uniform coating. The purpose of the flow stage is to form a uniform coating on the coating surface, laying the foundation for the cross-linking curing stage. If the flow is insufficient, it will cause unevenness, pinholes and other problems in the coating.

The powder coating is affected by its surface tension during the initial flow stage of baking and curing, and the overall flow speed is not very fast. As the temperature continues to increase and the surface tension of the powder coating particles decreases, the powder coating particles will begin to interact with each other and flow faster.

c. Cross-linking and curing stage

The cross-linking curing stage is the third stage of powder coating curing and generally takes 10-30 minutes. At this stage, the resin in the powder coating reacts chemically with the curing agent to form a hard coating film. The cross-linking curing reaction requires a certain amount of time and temperature to complete. The purpose of the cross-linking curing stage is to form a hard, durable coating on the coating surface. If cross-linking and curing are incomplete, problems such as cracking, blistering, and peeling of the coating will occur.

Here are some considerations during the cross-linking curing stage:

- The baking temperature should be controlled within an appropriate range to avoid the temperature being too high or too low.

- The baking time should be adjusted according to the type of powder coating, coating thickness, and workpiece size.

- Workpieces should be placed evenly in the baking oven to avoid local overheating or overcooling.

2. Powder coating baking and curing parameters

a. Baking temperature

Baking temperature is one of the most important parameters in the curing process of powder coatings. Usually the baking and curing temperature of powder coatings is between 150°C and 220°C. Because the ingredients of powder coatings vary greatly, the baking temperature of powder coatings depends on the type of ingredients and spray thickness of the coating.

b. Baking time

The baking and curing time of powder coatings is generally about 10-30 minutes. Depending on the type of powder coating and spray thickness, the baking and curing time can be adjusted appropriately. Bake curing for too short a time may result in the coating being incompletely cured, while baking for too long may result in over-curing or discoloration.

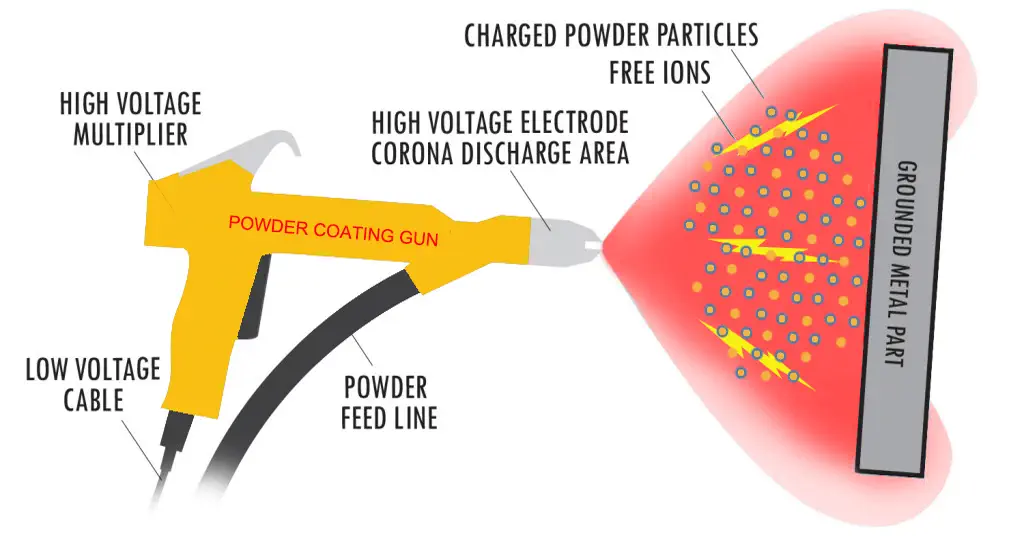

c. Spray thickness

Most powder coatings are sprayed by workers using electrostatic spray guns. However, this spraying method is often less efficient and cannot ensure uniform spray thickness on the workpiece. Ideally, a robotic arm can be used for fully automatic spraying, or a thickness measuring instrument can be used to measure the spray thickness to ensure that the powder coating can evenly cover the surface of the workpiece.

d. Baking equipment

Large professional industrial ovens can ensure uniform temperature distribution in the oven and effectively control the heating of workpieces in the oven. But when some special powder coating types require specific curing temperatures and temperature profiles, professional large ovens can achieve this goal.

The baking curing of powder coatings is an important factor affecting the quality of the coating. The baking and curing process of powder coatings is divided into three stages: agglomeration stage, flow stage and cross-linking curing stage. The agglomeration stage is when the coating forms an initial bonding layer; the flow stage is when the coating forms a uniform coating; the cross-linking and curing stage is when the coating forms a hard coating. During the baking and curing process of powder coatings, special attention needs to be paid to baking documents, baking time, spray uniformity, placement of workpieces and other factors. If you encounter difficult-to-solve problems during the baking and curing process of powder coatings, please feel free to contact UCOAT. As China’s top powder coating R&D and manufacturer, we will provide you with free powder coating baking and curing solutions.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Latest news

Have Anything To Ask Us?