What is the adhesion principle of powder coating?

From architectural decoration and electronic equipment to auto parts and furniture production, powder coatings provide diverse coating options for various fields and products. In order to ensure that these powder coatings can adhere firmly to surfaces of different materials for a long time, it is necessary to understand the adhesion principles of powder coatings. As a leader in the field of powder coatings, UCOAT has decades of R&D and production experience in this field. We will provide you with more comprehensive and detailed professional knowledge related to powder coatings and uncover the adhesion principle of powder coatings.

1. Adhesion principle of powder coating

The adhesion mechanism of powder coatings is one of the core elements that ensures their strong adhesion on different surfaces. Understanding this mechanism is critical to producing high-quality coatings. In this section, we’ll dive into the adhesion mechanisms of powder coatings, including the importance of surface preparation, electrostatic adhesion effects, and the bake-cure process.

a. Preparing the surface of the object to be sprayed

The adhesion of powder coatings is closely related to the cleanliness of the surface. Any remaining dirt, grease, or other contaminants will affect the adhesion properties of the coating. Therefore, the surface must be thoroughly cleaned and degreased before painting. This can be achieved by solvent cleaning, ultrasonic cleaning or heat treatment.

In addition, the roughness of the sprayed surface is also critical to the adhesion properties of the powder coating. Powder coatings require sufficient surface roughness to provide mechanical anchor points to ensure adhesion. Typically, sanding, blasting, or other surface treatments are used to increase surface roughness and improve coating adhesion.

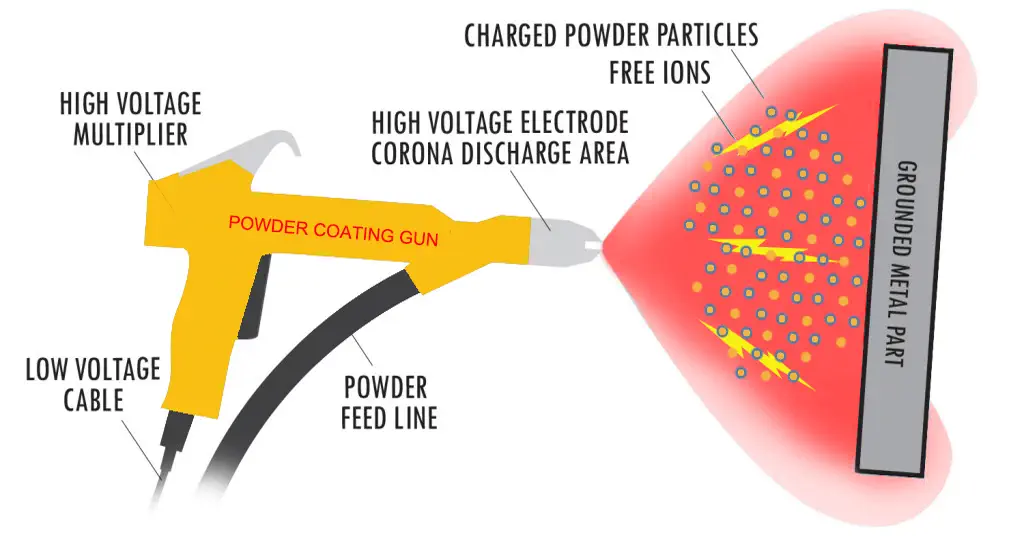

b. Electrostatic adsorption powder coating

The electrostatic adsorption effect of powder coatings is one of the key mechanisms to achieve coating adhesion. During the coating process, powder coating is sprayed onto the surface of the object to be painted by a spray gun with an electrostatic charge. Because the charged paint particles have an opposite charge to the surface to be coated, they are strongly attracted to the surface, forming a uniform powder coating.

c. Baking and curing of powder coatings

Once the powder coating has evenly adhered to the surface, the bake-curing process ensures that the coating becomes strong and durable. In this process, the coating is exposed to high temperatures for a period of time, with the powder coating particles melting and flowing, then rapidly cooling to form a hard coating. This process not only improves the durability of the coating but also further enhances its adhesion.

2. What are the factors that affect the adhesion of powder coatings?

a. Temperature

Normally, the temperature during the coating process should be above the melting point of the powder coating to ensure that the powder coating can be evenly applied to the surface of the object. The melting temperature of powder coatings is around 180°C to 220°C, and the specific melting documentation depends on the formulation and ingredients of the paint. Good temperature control helps powder coating particles melt and flow better, thereby improving the surface adhesion of powder coatings.

b. Humidity

The humidity of the powder coating spraying environment will directly affect its surface adhesion. Too high or too low ambient humidity can lead to problems such as bubbles and uneven paint flow.

c. Substrate type

Different types of substrates will have different effects on the adhesion properties of powder coatings. A substrate surface that is too smooth will cause the powder coating to fail to adhere firmly, while a rough substrate surface will appear uneven after spraying a light powder coating. We can use any sandblasting or sanding process to treat the surface of the substrate in advance.

d. Coating thickness

Thicker powder coatings will have problems with peeling off and cannot maintain adhesion on the surface of the object well. The intelligent robotic arm electrostatic spray gun can well control the spray thickness on the surface, but traditional manual spraying often has certain problems.

e. Composition of powder coatings

The composition of powder coatings has a direct impact on its adhesion properties. Different types of powder coatings have different chemical compositions and properties. Epoxy powder coatings, polyester powder coatings, acrylic powder coatings, etc. have better adsorption properties, while other types of powder coatings perform weakly in this field.

3. How to improve the adhesion performance of powder coatings?

In order to optimize the surface adhesion of powder coatings, we can take some corresponding measures to improve it. These optimization measures include surface preparation, selecting the appropriate powder coating type and controlling coating parameters.

a. Surface treatment

Sanding and sandblasting can perform good surface treatment on metal materials to be sprayed, improve the roughness of the surface, allow the powder coating to be better anchored on the metal surface, and improve the adhesion performance. In addition, pickling and phosphating can effectively remove oxides, oil dirt and grease on the surface of the object to be sprayed, and at the same time form a chemical reaction on the surface to generate a layer of compounds that are conducive to adhesion.

b. Select the appropriate powder coating type

Different types of substrates combined with different types of powder coatings can perform better in terms of adhesion performance. Steel substrates are suitable for epoxy resin powder coatings, aluminum products are suitable for polyester resin powder coatings, epoxy resin powder coatings should be selected for wood surfaces, low-temperature curing powder coatings should be selected for glass substrates, and special substrates for ceramic lamps should be selected. of powder coating.

c. Control spraying parameters

Make sure the powder coating gun is set up correctly. The voltage, current and spraying distance of the spray gun will all affect the electrostatic adsorption effect. Proper adjustment of these parameters can achieve better adhesion performance. In addition, the baking time and baking temperature of powder coatings need to be strictly controlled after spraying to ensure that the baking parameters recommended by the manufacturer are followed.

An in-depth understanding of the adhesion principles of powder coatings can effectively improve existing spraying methods and adhesion effects. By improving the surface preparation of the object to be sprayed, the electrostatic adsorption effect and the baking and curing process, we can make the spraying effect of powder coating more satisfactory and achieve high-quality coating. Ucoat has decades of professional experience in the field of powder coating R&D and production. We are happy to provide you with high-quality various types of powder coatings and related customized powder coating solutions.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Latest news

Have Anything To Ask Us?