What is powder coating? Everything you should know

Powder coating is a dry finishing process used to apply a protective and decorative coating to various surfaces, including metal, plastic, and more. It involves spraying a fine powder of pigments and resins onto the surface and then baking it to create a durable and attractive finish. Powder coating offers excellent resistance to chemicals, corrosion, and UV rays, making it widely used in automotive, industrial, and household applications.

Ucoat has more than 20 years of professional experience in the field of powder coatings and is the top powder coating manufacturer in China. In this article, we will take an in-depth look at the history of powder coatings, the properties of powder coatings, the manufacturing process of powder coatings, and the application fields of powder coatings.

1. Development History of Powder Coatings

Daniel Gustin is recognized as the inventor of the powder coating process. He obtained the invention patent 2538562 of the powder coating process in 1945. This powder coating spraying process uses electrostatic adsorption to cover an object with a layer of powder coating and then cure it by heating. Fix the powder coating to the surface. The following are the main development milestones of powder coatings:

- 1950s: With the advancement of technology in the chemical industry, the preparation methods of powder coatings have been improved, including finer powders and increased color diversity.

- 1960s: During this period, powder coatings began to be widely used in the automotive industry and military fields to provide protective properties and durability of coatings.

- 1960s: During this period, powder coatings began to be widely used in the automotive industry and military fields to provide protective properties and durability of coatings.

- 1980s: Market demand for powder coatings continues to grow, and powder coating manufacturers add new formulations to meet the needs of different materials and applications.

- 1990s: Increased environmental awareness led to the development of powder coatings because it is a solvent-free coating that does not emit volatile organic compounds (VOCs) and unused powder can be recycled and reused.

- 2000s to present: The powder coating industry continues to thrive, with applications expanding into a variety of industrial and consumer goods industries, including furniture, bicycles, outdoor equipment, and sporting goods.

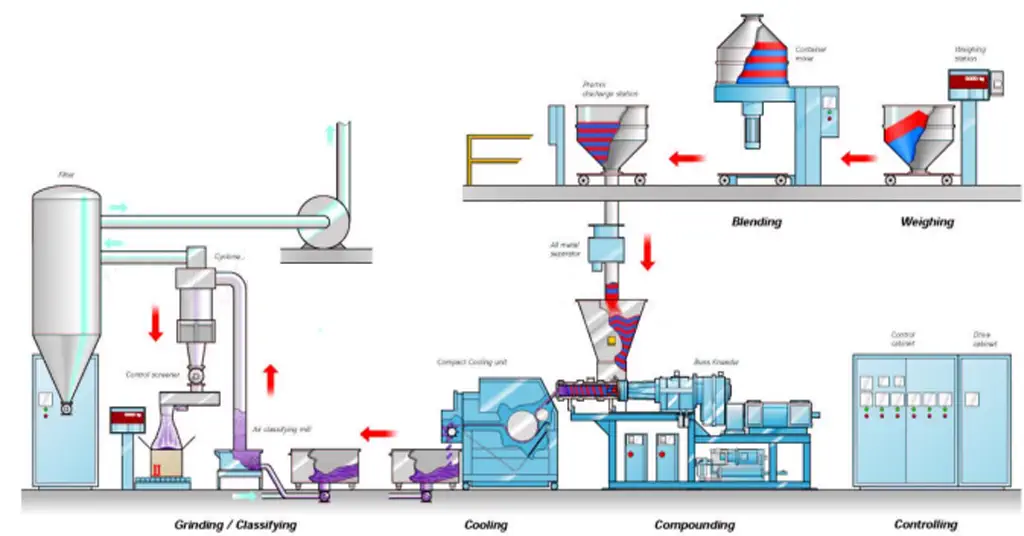

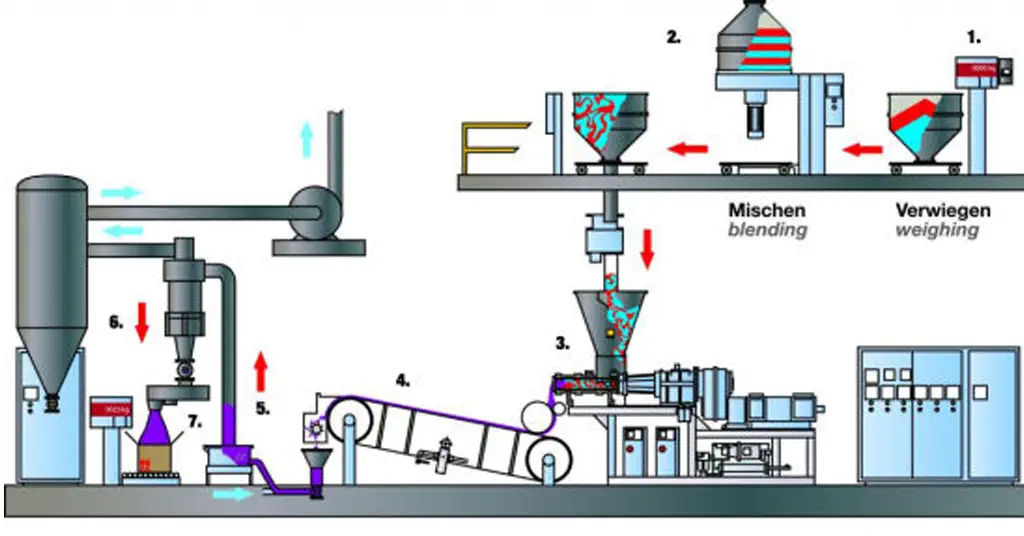

2. Manufacturing process of powder coating

Powder coatings usually require raw materials such as epoxy resin, color fillers, epoxy curing agents and modifiers to be mixed in a certain proportion, and then prepared and packaged according to specific production requirements. The common powder coating manufacturing process is usually divided into 5 links. The following are the specific powder coating manufacturing steps.

a. Preparation and preparation of raw materials

Different powder coating types will have big differences in the selection of raw materials. Resin is one of the main raw materials of powder coatings and is used to provide the curing properties and adhesion of the coating. Common resins include epoxy resin, polyester resin, polyimide resin, polyurethane resin and acrylic resin. Other powder coating raw materials also include pigments, additives (leveling agents, defoaming agents, hardeners, antioxidants, etc.), fillers (calcium carbonate, talc, silicates, iron oxide, etc.), curing agents (used Used to form a solid coating during the heat curing process of powder coatings).

b. Premixed raw materials

The premixing process is to mix the powder coating raw materials in the previous step in a special proportion according to the characteristics of the finished product to create a better physical standard for the high-temperature melted rubber compound in the next step. The key to this process is to control the pre-mixing time so that the raw materials of the powder coating can reach a uniform mixing state.

c. Melting and extrusion

The melting, mixing and extrusion process is an important step in the production of electrostatic powder. According to the mixing glue, the components of the powder coating are evenly dispersed in the molten state. Get rid of the separation of ingredients due to different proportions of raw materials during dry mixing in the previous step. The raw materials in the hot melt state are in a gel form and are extruded into thin sheets using an extruder.

d. Refrigeration, crushing and grinding

The powder coating extruded into thin sheets after hot melting is still in a high temperature state. At this time, timely cooling is required to avoid causing internal chemical reactions of the melt and affecting the quality of the final powder coating. The cooled flaky semi-finished products are crushed according to the particle size requirements using a crusher. The crushed powder coating is collected into the packaging machine when passing through the separation roller.

e. Screening and packaging

The packaging machine weighs and packages the powder coating from the previous step according to certain specifications. First pour the powder coating into a sealed plastic bag, then place the plastic bag into a carton. Finally, the production information is marked on the outer packaging of the powder coating and then transported to the warehouse for storage.

3. What are the characteristics and advantages of powder coating?

- Environmental protection: Powder coating is a solvent-free coating that does not contain volatile organic compounds (VOC) and has low environmental pollution. This helps reduce air pollution and harmful gas emissions. Click here to learn more about What are the advantages of powder coatings in environmental protection.

- High Durability: Powder coatings offer excellent weather and corrosion resistance, resisting UV rays, chemicals, moisture and mechanical abrasion, resulting in a long-lasting coating.

- Uniform coating: Powder coating can be evenly distributed on the surface of the workpiece without worrying about drips or drip marks, thus providing an even coating.

- High efficiency: Powder coating has no solvent volatilization during the coating process, so it has a high solid content. This enables high utilization of the coating and reduces waste.

- Diverse Colors and Effects: Powder coatings can be used to achieve a variety of colors, textures and effects, including smooth, textured, metallic and matte effects.

- Efficient coating speed: The coating speed of powder coating is relatively fast, and a large number of workpieces can be coated in a short period of time.

- Low operating costs: Powder coatings generally have lower operating costs because solvent recycling and disposal are not required.

- Suitable for a variety of materials: Powder coatings are suitable for coating a variety of materials including metal, plastic, wood and composite materials.

- Scratch Resistance: Powder coatings generally have good scratch resistance and are not easily damaged or scratched. Click here to learn more about Why powder coating has good wear resistance.

- One-time application: In most cases, powder coating requires only one application and does not require a primer or multiple coats

4. What are the common application fields of powder coatings?

c. Electronics and electrical appliances

g. Outdoor products

h. Pipes and pipe fittings

I. Sporting Goods

J. Medical Devices

As a common type of dry coating, powder coating has unparalleled characteristics and advantages over traditional paint and is often used in a variety of life and work scenarios. Different types of powder coatings have completely different ways of use according to their characteristics. They can have very good performance in terms of environmental protection, wear resistance, bright colors, scratch resistance, low-cost operation and universal applicability.

Have Anything To Ask Us?