What are the commonly used epoxy resins for powder coatings?

Table of Contents

Epoxy resin is one of the common raw materials for powder coatings. However, the composition of epoxy resin powder coatings varies greatly depending on the application scenario and target audience. Epoxy resin usually refers to a substance containing α- Methyl epoxyethane based thermoplastic resins can form non melting and non melting thermosetting polymers through chemical crosslinking. Chemically speaking, epoxy resin refers to a type of substance that contains two or more epoxy groups at the molecular end, between circular structures, or other intermediate positions, and can also generate thermosetting solids through chemical crosslinking. In this article, I will share with you six common types of epoxy resins used in the field of powder coatings.

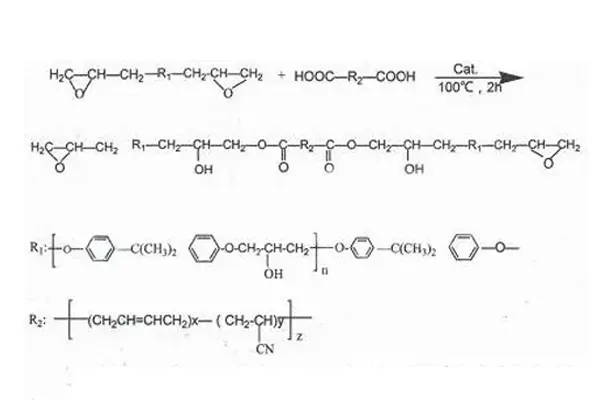

Bisphenol A type epoxy resin is obtained by polymerization of bisphenol A and epichlorohydrin. Depending on the synthesis method, there are two methods: one-step and two-step.

Epoxy value, softening point, organic chlorine, and inorganic chlorine are important indicators for evaluating the performance of epoxy resins. The bisphenol A structure has excellent anti-corrosion performance, thermal stability, and a certain degree of rigidity, making it convenient for powder storage and grinding.

Ether bonds have excellent flexibility and hydrolysis resistance, hydroxyl groups enhance the adhesion between coatings and substrates, and epoxy groups provide curing crosslinking groups.

N is the number of repeated units. The larger the value of n, the higher the epoxy resin model, the longer the molecular chain, the larger the molecular weight, the higher the viscosity, the lower the epoxy value, the higher the epoxy equivalent, and the better the flexibility.

Bisphenol A epoxy resin contains a large amount of benzene rings and has poor weather resistance. The epoxy powder coating made from it cannot be used outdoors.

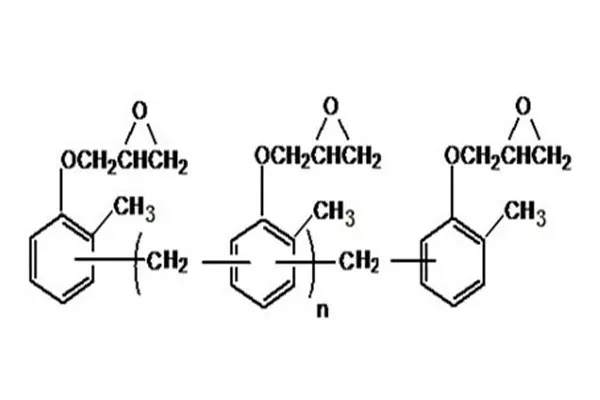

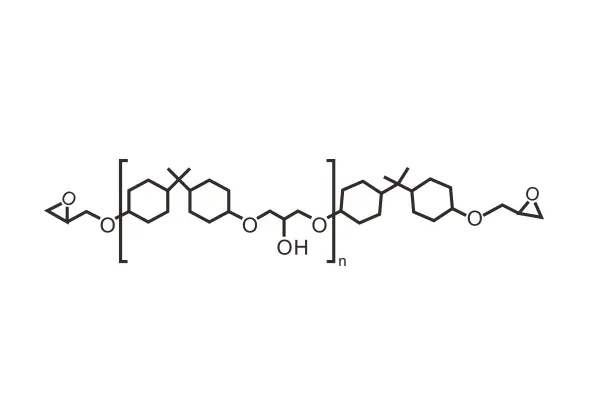

Replace the benzene ring in epoxy resin with a saturated six membered ring, which is called hydrogenated bisphenol A epoxy resin. The molecular structure of hydrogenated bisphenol A epoxy resin is shown in Figure 2, with R2 and R3 representing methyl groups.

Hydrogenated bisphenol A epoxy resin not only has the advantages of bisphenol A epoxy resin, but also has excellent weather resistance. The physical and mechanical properties of the coating formed after curing with hydrogenated bisphenol A epoxy resin remain basically unchanged after 1000 hours of aging, and its weather resistance is improved compared to bisphenol A type epoxy resin.

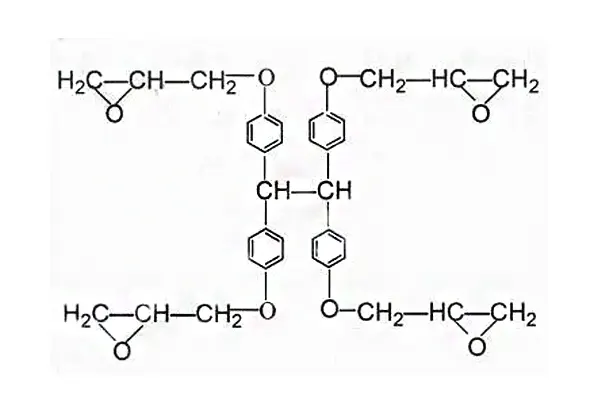

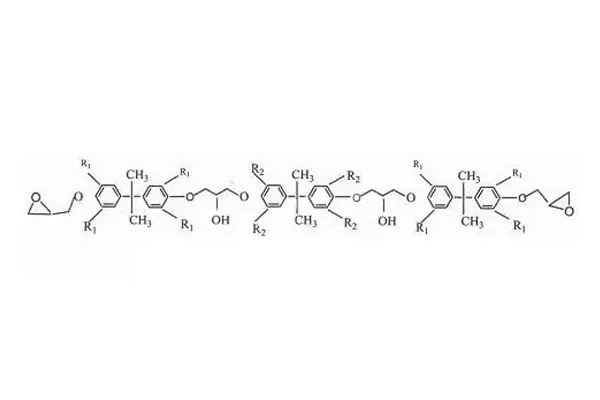

The functionality of bisphenol A epoxy resin is 2, and the crosslinking density of the coating is low, resulting in poor heat resistance and corrosion resistance. Multifunctional epoxy resin has a functional degree greater than 2, resulting in a high crosslinking density and good anti-corrosion performance of the cured film. The functional degree of commonly used multi functional epoxy resins in powder coatings is 4, such as tetraphenylethane epoxy resin.

Tetraphenylethane epoxy resin, also known as tetraphenylethane tetraglycidyl ether (t-PGEE), is a phenolic type epoxy resin. It is produced by the reaction of phenol and glyoxal in the presence of an acidic catalyst, and then reacted with epichlorohydrin in the presence of sodium hydroxide to produce tetraphenylethane.

Tetraphenylethane epoxy resin is a solid at room temperature, with a softening point of 75-80 ℃ and an epoxy value of 0.45-0.50mol/100g.

The steel bars used in large-scale projects such as high-speed rail and cross sea bridges need to be sprayed with epoxy powder coating to improve their anti-corrosion performance. Oil and natural gas transmission pipelines also need to be sprayed with epoxy powder coating to extend their service life.

Steel bars should bend at low temperatures and the coating should not show cracks; The bending coating of oil pipelines at -30 ℃ has no cracks, which poses high requirements for the flexibility of the coating. Ordinary bisphenol A epoxy resin is difficult to meet these requirements.

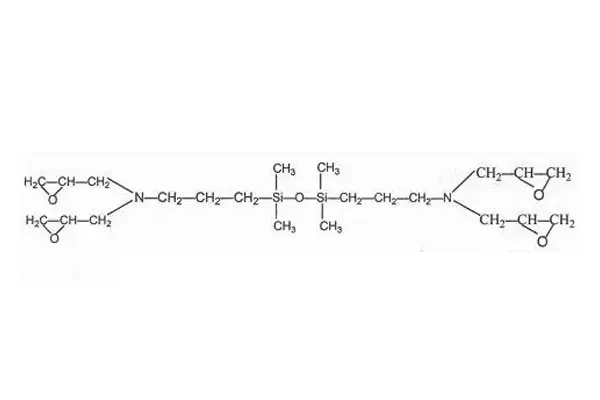

Therefore, it is necessary to toughen and modify ordinary epoxy resin. Nitrile rubber modified epoxy resin emerged. Linking rubber molecules into epoxy resin, and then reacting with curing agents, nitrile rubber segments are integrated into the polymer chains of the coating. Due to the strong flexibility of nitrile rubber, it forms a “sea island” structure with the rigid chains of epoxy resin, effectively improving the flexibility of the coating and avoiding cracking during low-temperature bending.

The Si-O bond energy is very high, at 106 kcal/mol; In addition, Si-O bonds are prone to rotation, and polymer molecular chains containing Si-0 bonds are highly curled, exhibiting strong flexibility.

Therefore, introducing Si-0 bonds into epoxy resin can not only improve the flexibility of the coating, but also enhance the heat resistance of the coating.

The polysiloxane obtained from four types of organosilicon monomers, namely methyl, phenyl, hydroxyl, and ethoxy polysiloxane, undergoes grafting reaction with epoxy resin under the action of a catalyst. After modification, the Tg of the coating is increased by 92 ℃, and the Ti (starting temperature of thermal decomposition) and Tox (peak temperature of thermal decomposition) are increased by about 30 ℃, greatly improving the heat resistance of the coating.

Introducing Si-0 bonds into multifunctional epoxy resins not only provides high crosslinking density and heavy corrosion resistance, but also flexibility and heat resistance provided by Si-O bonds, resulting in superior overall performance.

High film glass transition temperature (Tg) epoxy resin refers to a type of epoxy resin with a high glass transition temperature (Tg) of the cured coating, usually with a coating Tg ≥ 120 ℃.

The ordinary bisphenol A type epoxy powder coating has a Tg<120 ℃ and cannot transport high-temperature oil and gas. High film Tg epoxy resin is the solution to this problem. The structure is shown in Figure 6, and the substituent can be halogen or benzene ring.

In ordinary bisphenol A type epoxy resin, the substituent is H or CH3, the steric hindrance is small, the coating chain segments are easy to move, and the coating Tg is low. The substituents in high film Tg epoxy resin are halogens or benzene rings, which have high steric hindrance and difficult chain segment movement. After curing, the Tg of the coating can reach 160 ℃, expanding the application range of epoxy powder coatings.

Another way to prepare high film Tg epoxy resin is to replace the glycerol ether structure in ordinary bisphenol A type epoxy resin with a hydroxyl ether, ketone ether, or rigid ring structure.

The ordinary bisphenol A type epoxy resin contains a glycerol ether structure, which improves the flexibility of the epoxy resin and also reduces the Tg of the coating.

Replacing the glycerol ether structure in ordinary epoxy resin with a hydroxyl ether, ketone ether, or rigid ring structure increases the rigidity of the molecular main chain, making it difficult for the molecular chain segments to move, thereby greatly improving the Tg of the coating. The Tg of this resin cured coating can reach over 180 ℃.

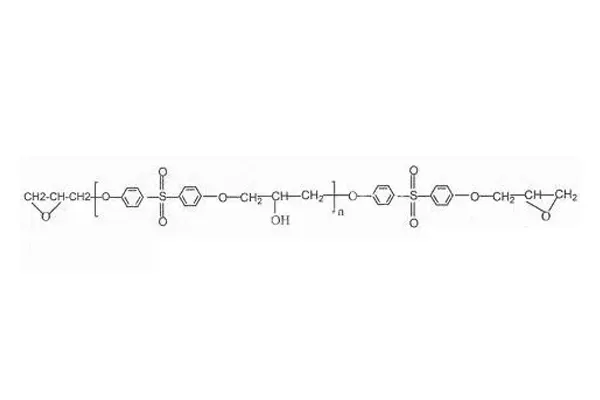

Bisphenol S-type epoxy resin can also increase the Tg of the coating. Due to the interactions between sulfone groups and hydrogen bonds formed between sulfone groups and hydroxyl groups in bisphenol S-type epoxy resin, intermolecular sliding is restricted, thereby increasing the Tg of the coating film.

Bisphenol S-type epoxy resin also has excellent heat resistance, and the hot deformation temperature is 60 and 70 ℃ higher than that of Bisphenol A-type epoxy resin. The structure of bisphenol S-type epoxy resin is shown in Figure 7.

Epoxy resin is a multifunctional thermoplastic resin that forms thermosetting polymers through chemical crosslinking, and is widely used in anti-corrosion, insulation, heat resistance, and decorative fields. Their characteristics include excellent corrosion resistance, insulation, heat resistance, and flexibility. Bisphenol A epoxy resin is a common type, which is made through specific synthesis methods and has good anti-corrosion and thermal stability properties. In addition, there is also hydrogenated bisphenol A epoxy resin, known for its excellent weather resistance. Multi functional epoxy resins are commonly used in powder coatings due to their high crosslinking density and anti-corrosion properties. Nitrile rubber modified epoxy resin and silicon modified epoxy resin respectively provide additional flexibility and heat resistance, making them suitable for specific industrial applications. High film glass transition temperature (Tg) epoxy resin can withstand higher temperatures due to its high Tg value, expanding the application range of epoxy resin. The diversity and characteristics of these resins make them very important and practical in many fields.

Have Anything To Ask Us?