UV Resistance in Pure Polyester Powder Coatings

Pure polyester powder coatings play an important role in today’s surface protection applications. Among them, its UV resistance is particularly interesting. UV rays may not only cause fading of surface color, but may also cause more serious damage to physical properties. As an expert in the field of powder coatings, I’ll give you an in-depth look at how pure polyester powder coatings have made huge strides in protecting surfaces from UV rays, and how they actually work in different applications.

1. Introduction

a. The Impact of UV Radiation on Coatings

UV radiation, a significant component of sunlight, can have a detrimental impact on various coatings. This natural phenomenon not only causes aesthetic issues, such as fading and discoloration, but also poses more serious challenges, including the deterioration of physical properties. In the realm of coatings, it’s crucial to understand how UV radiation affects their performance.

Fading and Discoloration: UV rays can break down the molecular structure of coatings, leading to the fading of colors and an unsightly discoloration. This effect is particularly concerning in outdoor applications where appearance matters, such as architectural finishes and automotive coatings.

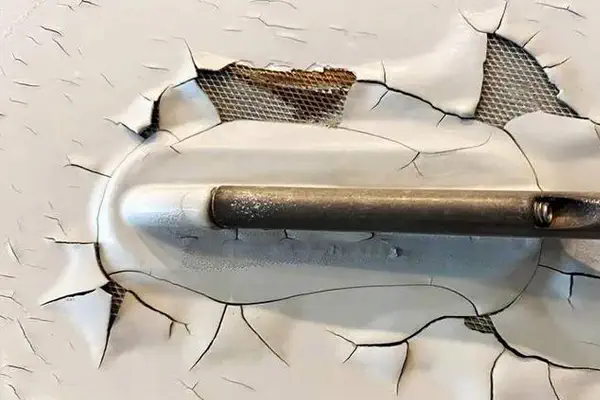

Reduced Durability: UV exposure can weaken the protective properties of coatings, making them more susceptible to abrasion, corrosion, and other environmental stresses. This deterioration can compromise the longevity of the coated surface.

Safety Concerns: In certain industrial applications, such as in the aerospace and marine sectors, UV-induced coating degradation can pose safety risks. It’s vital to prevent coatings from becoming brittle or losing their integrity due to prolonged UV exposure.

b. Importance of UV Resistance in Powder Coatings

Powder coatings have gained prominence in the coatings industry due to their versatility and durability. UV resistance is a key factor that significantly impacts the performance and longevity of powder coatings. Understanding the importance of UV resistance in powder coatings is essential for both manufacturers and end-users.

Outdoor Applications: Powder coatings are widely used in outdoor applications, such as on metal structures, architectural elements, and outdoor furniture. UV resistance is critical to ensure these coatings maintain their appearance and protective qualities over time.

Automotive Industry: In the automotive sector, powder coatings are applied to various components, from wheels to trim parts. UV resistance is vital to prevent color fading and deterioration of these coatings, ensuring vehicles maintain their aesthetic appeal.

Industrial Equipment: Powder-coated industrial equipment often operates in outdoor environments. UV resistance is crucial for preventing coating degradation, which can lead to structural weaknesses and corrosion issues in critical machinery.

2. UV Resistance in Pure Polyester Powder Coatings

a. The Chemistry of UV Resistance

Understanding the chemistry behind UV resistance in pure polyester powder coatings is essential to grasp how these coatings effectively shield surfaces from UV damage.

Molecular Bonds: UV resistance in powder coatings relies on strong molecular bonds that can withstand UV radiation. The chemical composition of pure polyester resins plays a crucial role in providing these robust bonds.

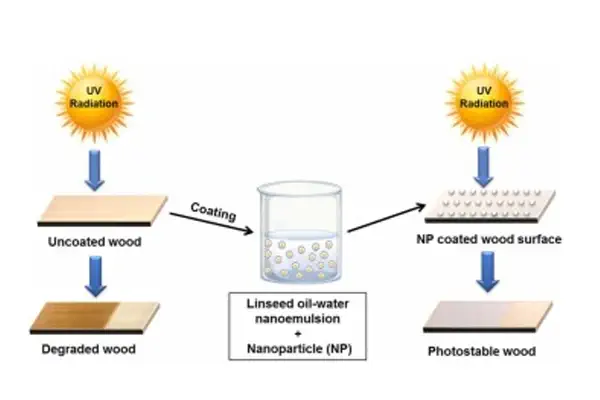

Photostabilizers: UV resistance can be enhanced by incorporating photostabilizers into the coating formulation. These compounds act as a shield, absorbing and dissipating UV energy before it can interact with the coating’s molecular structure.

b. Cross-Linking and Polymer Structure

Cross-Linking Agents: Cross-linking agents are added to the powder coating formulation to create a three-dimensional network within the polymer structure. This network enhances the coating’s resistance to UV-induced degradation.

Polyester Backbone: The inherent structure of polyester resins also plays a role. Polyesters with highly saturated backbones are more resistant to UV radiation because they are less susceptible to UV-induced breakdown.

c. Types of UV Absorbers and Stabilizers

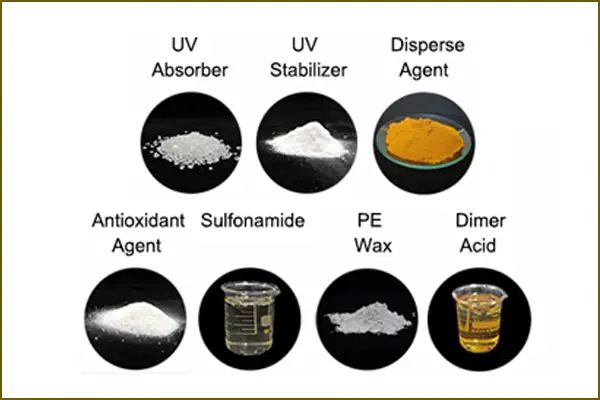

Various types of UV absorbers and stabilizers can be incorporated into pure polyester powder coatings to bolster their UV resistance.

UV Absorbers: UV absorbers are compounds that absorb UV radiation and convert it into harmless thermal energy. These can include benzotriazoles, benzophenones, and hindered amine light stabilizers (HALS).

Hindered Amine Light Stabilizers (HALS): HALS are particularly effective in preventing UV-induced degradation by inhibiting free radical formation. They work by trapping and neutralizing free radicals that can initiate destructive chain reactions.

3. Specific Applications of Pure Polyester Powder Coatings with UV Resistance

Pure polyester powder coatings with UV resistance find a multitude of applications in the realm of outdoor architectural design, where aesthetics and long-term performance are of utmost importance.

Façades and Cladding: UV-resistant coatings are a popular choice for building façades and cladding materials. They maintain the vibrancy and integrity of the architectural design, even in the face of relentless sun exposure.

Window Frames and Extrusions: Coating window frames and extrusions with UV-resistant powders ensures they withstand UV rays without fading or deteriorating. This is especially crucial for commercial and residential structures.

Roofing Materials: In roofing applications, UV resistance is vital to prevent color fading and maintain the durability of roofing materials. These coatings contribute to the overall longevity of the roofing system.

The outdoor furniture and decor industry benefits significantly from the use of pure polyester powder coatings with UV resistance, ensuring that outdoor spaces remain inviting and stylish.

Patio Furniture: Powder-coated patio furniture is a popular choice for homeowners and businesses. UV-resistant coatings protect furniture from fading, allowing it to maintain its appeal season after season.

Garden Accessories: Decorative items like garden gates, trellises, and decorative planters receive extended life and look great with UV-resistant coatings. These coatings help protect the investments made in outdoor spaces.

Play Equipment: Playgrounds and recreational areas with UV-resistant coatings ensure children’s safety and aesthetics, even in constant outdoor exposure.

c. Marine and Coastal Applications

Marine and coastal environments present some of the harshest conditions for coatings, making UV resistance crucial for both aesthetics and performance.

Boat Finishes: UV-resistant coatings for boats protect against the sun, saltwater, and harsh marine conditions. They keep vessels looking pristine and ensure the coatings’ longevity.

Coastal Structures: Coastal constructions, such as piers and bridges, require UV-resistant coatings to withstand the salt-laden air and relentless sun exposure. These coatings help maintain structural integrity and extend the lifespan of these vital installations.

Offshore Equipment: Equipment used in offshore and marine industries benefits from UV-resistant coatings to prevent degradation and maintain operational safety.

the significance of UV resistance in pure polyester powder coatings cannot be overstated. Understanding the chemistry behind UV resistance, the role of cross-linking and polymer structure, and the types of UV absorbers and stabilizers is pivotal in crafting coatings that stand up to the relentless force of UV radiation. The benefits of UV resistance, including extended longevity and durability, the preservation of color and aesthetics, and reduced maintenance and repair costs, make these coatings a valuable choice for a wide range of applications. From outdoor architectural use to outdoor furniture, decor, marine, and coastal applications, UV-resistant pure polyester powder coatings enhance performance, protect investments, and contribute to the longevity of surfaces and structures.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Latest news

Have Anything To Ask Us?