The secret of powder coating corrosion resistance

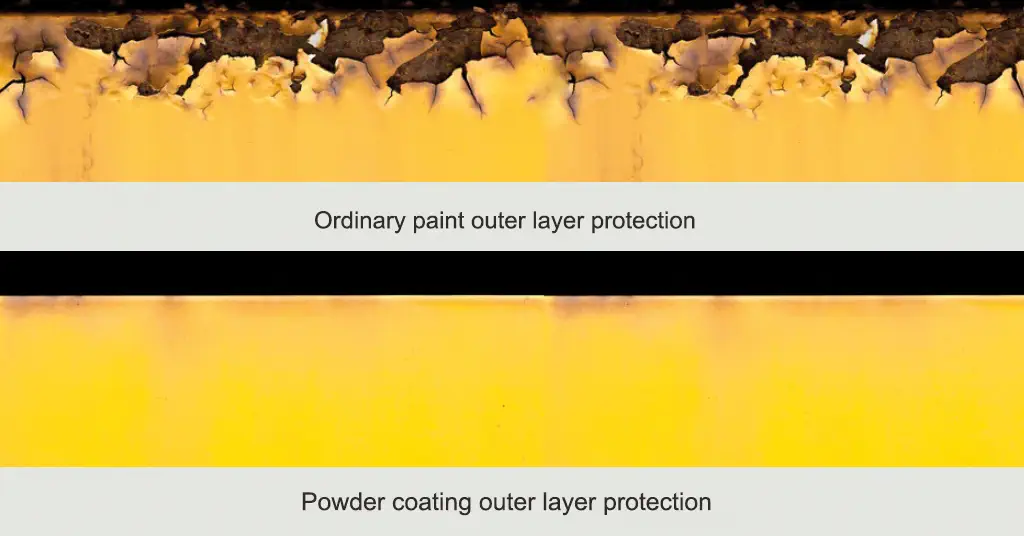

You must have seen rusty pipes outdoors, but at the same time, some painted pipes can maintain a smooth appearance and beautiful color. You might say this is because of the effect of the paint, but it turns out that the protective layer of paint is also fragile in any harsh external environment. As the first choice for metal protection—powder coating has excellent performance in corrosion resistance. The seemingly ordinary powder can provide good protection for metal and other workpieces in harsh environments. Today, let’s take a journey of exploration into the corrosion resistance of powder coatings.

1. Principles and mechanisms of corrosion resistance of powder coatings

The principles and mechanisms of powder coating corrosion resistance involve multiple factors, including the composition of the powder coating, the spraying process, and the structure of the powder coating. The following are the basic principles and mechanisms of corrosion resistance of powder coatings.

a. Blocking protection

After baking and solidification, the powder coating will form a uniform and dense coating on the surface of the workpiece. This coating can provide a physical barrier to prevent corrosive substances such as oxygen, moisture, and salt from contacting the metal surface, thereby slowing down the corrosion process. This barrier protection prevents the early stages of oxidation and corrosion of the workpiece.

b. Chemical reaction inhibition

The ingredients of some powder coatings can include anti-corrosion additives, which can chemically react with corrosive substances on the metal surface, thereby slowing down the rate of corrosion. For example, the zinc in zinc powder coatings can react with oxygen to form a zinc oxide layer that prevents further oxidative corrosion.

c. Sealing

Powder coating can form a continuous, non-porous coating after application, ensuring that there is no exposed metal surface. This helps reduce the intrusion of corrosive substances and prevents the spread of corrosion

d. Stability of the protective film

Powder coatings usually have high weather resistance and chemical stability, which allows the coating to maintain its protective properties under harsh environmental conditions and is not easy to crack or fall off.

2. Corrosion resistance test of powder coating

Different powder coatings have greatly different performance in different corrosive environments. In order to better select the type of powder coating suitable for a specific corrosive environment, we need to conduct strict tests on the corrosion resistance of powder coatings. The following are some common testing methods for the corrosion resistance of powder coatings.

In the salt spray test, the test workpiece with powder coating on the surface needs to be exposed to the salt spray environment to simulate a corrosive environment. The test time can be adjusted according to the actual working environment, usually around hundreds of hours. During the test, it is necessary to observe whether there are rust spots, powder coating peeling or signs of corrosion on the surface of the test tool.

The acid-base mist test is to put the sample into an acidic or alkaline solution and spray it at a constant temperature and humidity to simulate the acid-base corrosion process in the environment to evaluate the corrosion resistance of the powder coating. Common acid-base spray test standards include ISO 9227:1995 (acetate salt spray test), ISO 9227:2017 and ASTM B117-2020.

Humidity testing is used to simulate the corrosion process of powder coatings under high humidity conditions. The tools to be tested need to be placed in a high humidity environment and are usually tested at a constant temperature. During the test, it is necessary to observe whether foaming, peeling, oxidation or other signs of corrosion appear on the surface of the workpiece.

3. Advantages of powder coating

- Barrier protection: Powder coating can form a uniform, continuous and dense coating, covering the surface of the object being coated. This coating provides effective barrier protection, preventing oxygen, moisture, salt and other corrosive substances from reaching the metal surface, thereby slowing down the occurrence of corrosion.

- Chemical stability: Some powder coating ingredients include anti-corrosion additives that can chemically react with corrosive substances on the metal surface to form a protective oxide layer or compound. For example, the zinc in zinc powder coatings can react with oxygen to form a zinc oxide layer, which resists oxidative corrosion.

- Durability of corrosion resistance: Powder coatings generally have high weather resistance and chemical stability, so they can maintain their protective properties for a long time under harsh environmental conditions. This durability helps reduce the need for maintenance and coating replacement.

- Appearance retention: Powder coatings generally maintain their appearance for a long time and are not prone to fading, oxidation or discoloration. This makes it ideal for use in applications where good appearance is required, such as cars, buildings, furniture, etc.

- Environmentally friendly: Powder coatings generally do not contain volatile organic compounds (VOCs), which helps reduce environmental pollution. In addition, there is no need to use harmful organic solvents, reducing risks in the work environment.

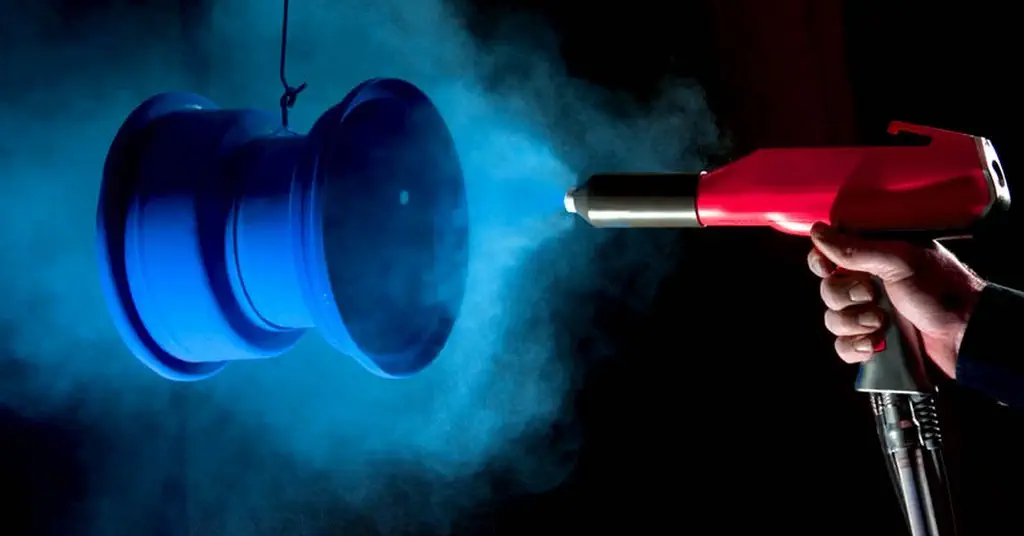

- Uniform Coverage: The electrostatic adsorption properties of powder coatings enable it to evenly cover the surface of complex-shaped objects, ensuring a consistent coating without the need for additional coating steps.

- Reduced waste: Powder coatings create less waste than liquid coatings because the unused powder can be recycled and reused.

In this article, we take an in-depth look at the exceptional corrosion resistance of powder coatings, revealing the secrets behind this coating. We explain in detail the manufacturing process of powder coating and the principles and mechanisms of how it resists corrosion. Not only that, but we also highlight the many benefits of powder coating, including long-term protection, environmental friendliness and a variety of appearance options. By gaining an in-depth understanding of the corrosion-resistant properties of powder coatings, we hope you can better understand this outstanding technology and make informed coating choices in its projects and applications. If you have any difficult questions about the powder coating field, we can provide you with reliable solutions based on decades of professional experience. Welcome to contact us.

Have Anything To Ask Us?