Testing and quality control of pure polyester powder coatings

In the world of coatings, achieving excellence isn’t just a matter of aesthetics—it’s a pursuit of uncompromising quality. “Testing and quality control of pure polyester powder coatings” delves deep into the very core of this endeavor. As an expert in the field, I invite you to explore the essential processes and meticulous assessments that define the standard for pure polyester powder coatings. In this article, we’ll unravel the intricate web of tests and quality control measures, revealing the keys to precision, durability, and reliability in this specialized coating industry. Let’s embark on a journey that ensures your coatings meet the highest standards and performance expectations.

Powder coating is a common surface coating technology that is widely used to improve the appearance of products, protect surfaces, and provide wear and corrosion resistance. To control the product quality of powder coatings, the following key factors need to be considered.

a. Raw material control

Resin: Choose the type of resin appropriate for your specific application, ensuring resin quality and purity. Conduct receiving inspections to verify raw materials meet specifications.

Pigments and Additives: Select appropriate pigments and additives to meet color and performance requirements. Make sure the pigments do not disperse or settle over time to avoid uneven color.

Fillers: If necessary, add appropriate amounts of fillers to adjust the density and properties of the coating. Make sure filler particle size and distribution are consistent.

b. Mixing and Homogeneity

Use high-quality mixing equipment, such as a twin-screw mixer, to ensure the raw materials are thoroughly mixed.

Regular sampling is taken for testing during the mixing process to ensure that the raw materials are evenly mixed and there are no local inhomogeneities.

Control mixing time and temperature to ensure thorough mixing but not overheating or reducing mix quality.

c. Granularity control

Particle size analysis was performed to determine the particle size distribution of the powder.

Particle size is measured using a screen or laser particle sizer, then production parameters are adjusted to meet specifications.

Monitor particle size regularly to ensure consistency and make appropriate adjustments if necessary.

d. Curing agent ratio

Precisely weigh and proportion the hardener to ensure the powder coating has the required hardness and durability.

Use an automatic batching system to ensure the accuracy and stability of the batching ratio.

Precise flow control and feedback mechanism to correct any ratio deviation

2. Types of Powder Coating Tests

In the realm of powder coating, rigorous testing is the cornerstone of quality assurance. Understanding the nuances of different tests and their operational intricacies is pivotal to producing coatings that meet exacting standards. In this section, we will delve into various types of powder coating tests, providing comprehensive insights into their operating environments and procedures.

a. Adhesion Testing

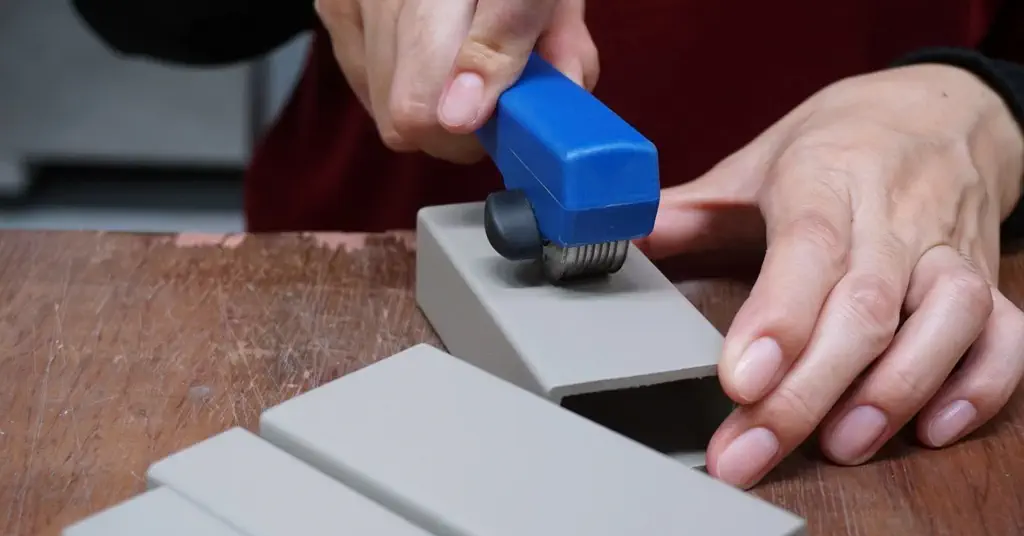

Cross-Cut Test: The Cross-Cut Test is conducted in a controlled laboratory environment. Here’s how it works:

Start by making a series of intersecting cuts on the coated surface using a cutting tool with defined specifications.

Apply a piece of adhesive tape to the cross-cut area and firmly press it down.

Swiftly remove the tape in a peeling motion, observing any coating fragments that come off with the tape.

- The percentage of coating removed, as well as the pattern of failure, provides insights into adhesion strength.

Pull-Off Adhesion Test: This test is generally performed using specialized equipment and follows these steps:

Attach a pull-off adhesion tester to the coated surface, ensuring a secure connection.

Gradually apply force, pulling the tester away from the substrate.

The force required to detach the coating is measured and recorded, indicating adhesion strength.

b. Coating Thickness Measurement

Dry Film Thickness Gauge: Measuring coating thickness with this gauge involves:

Placing the gauge on the coated surface and ensuring proper contact.

Taking multiple readings at different locations to establish an average thickness.

The gauge displays the thickness in microns or mils, offering a precise measurement of the dry film thickness.

Magnetic Pull-Off Thickness Gauge: Using a magnetic pull-off thickness gauge involves the following steps:

- Apply the gauge to the coated surface, ensuring it adheres through magnetic attraction

Gradually pull the gauge away from the substrate.

The gauge registers the distance it moves before the coating detaches, providing the coating’s thickness measurement.

c. Visual Inspection

Checking for Coating Uniformity: Visual inspection takes place in a well-lit, controlled environment. It involves:

A thorough visual examination of the entire coated surface.

Observing for variations in color, texture, or thickness that could indicate uneven application.

Identifying Visual Defects: To identify visual defects, follow these steps:

Examine the coated surface closely for imperfections such as craters, pinholes, or uneven texture.

Document and categorize defects based on their nature and severity.

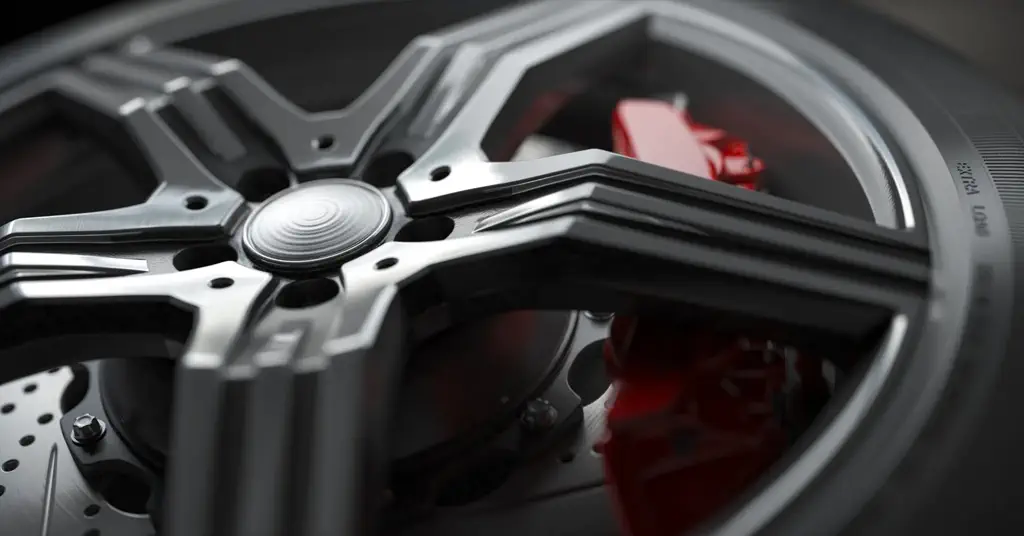

d. Impact Resistance Testing

Impact resistance testing typically occurs in a specialized testing facility or laboratory:

A standardized impactor, often a weighted pendulum or falling weight, is used to strike the coated surface with a controlled force.

The coating’s response to impact, including the formation of cracks or damage, is assessed.

This test helps determine the coating’s ability to withstand physical impacts.

e. Salt Spray Testing

Salt spray testing is conducted in a controlled chamber:

The coated test panels are exposed to a saltwater mist, simulating corrosive conditions.

The panels are monitored over a specified period to evaluate any signs of corrosion or degradation.

f. UV Resistance Testing

UV resistance testing typically involves exposure to controlled UV radiation:

Coated samples are placed in a UV chamber and subjected to accelerated UV radiation.

The samples are periodically evaluated for changes in color, gloss, and degradation over time.

g. Chemical Resistance Testing

Chemical resistance testing is performed in a controlled laboratory setting:

The coated samples are exposed to specific chemicals or solvents.

The samples are observed for any adverse reactions, including changes in appearance or integrity.

h. Gloss and Color Measurement

Gloss and color measurement require specialized equipment:

Gloss is measured using a gloss meter, which quantifies the coating’s reflective properties.

Color is assessed using a colorimeter or spectrophotometer, providing precise data on color consistency.

These comprehensive descriptions of test environments and procedures should serve as a valuable reference for ensuring the quality and performance of powder coatings in various applications.

Quality control and testing are pivotal aspects of ensuring the excellence of pure polyester powder coatings. Adhesion testing, including the Cross-Cut and Pull-Off Adhesion tests, evaluates the coating’s bond strength. Coating thickness is measured with precision using Dry Film Thickness Gauges and Magnetic Pull-Off Thickness Gauges. Visual inspection identifies uniformity and defects. Impact resistance, salt spray, and UV resistance testing assess durability. Chemical resistance testing gauges the coating’s resilience against chemicals. Gloss and color measurement maintain the desired appearance. By incorporating these tests, manufacturers guarantee coatings that surpass industry standards and meet customer expectations, making pure polyester powder coatings a dependable choice in various applications.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?