Quality Control Of Powder Coating

Strict selection of powder coating raw materials

Raw material selection and quality control are critical to producing high-quality powder coatings. Before producing powder coatings, we will strictly review the resin type based on order requirements. Raw materials such as epoxy resin, polyester resin, polyethylene, polyurethane, etc. all have different performance characteristics. We will choose according to the chemical corrosion resistance, wear resistance and high temperature resistance of the actual powder coating performance requirements. In addition, related influencing factors such as the color, additives, and powder particle size distribution of powder coatings are also key aspects of our strict control of raw materials. Purchased powder coating raw materials are stored under appropriate temperature and humidity conditions to prevent contamination from moisture and impurities. Under special circumstances, we will also test the purity of raw materials for powder coatings to ensure that they can meet production requirements.

Powder coating premixing process

The premixing link of powder coating is very important. It requires precise control of the mixing ratio of the powder coating to achieve the desired performance. In addition to the precise control of the mixing ratio of powder coating raw materials, the mixing time also needs to be precisely controlled. If the raw materials of the powder coating are mixed for insufficient time, the raw material layering will not be fully integrated, thus affecting the performance of the powder coating. In addition, the appropriate mixing temperature is also very critical. Too high a mixing temperature will cause discoloration and degradation of the raw materials of the powder coating. A mixing temperature that is too low will not ensure full integration between the raw materials. UCOAT has implemented various strict control measures in the pre-mixing process of powder coatings to ensure the smooth progress of the pre-mixing process of powder coatings.

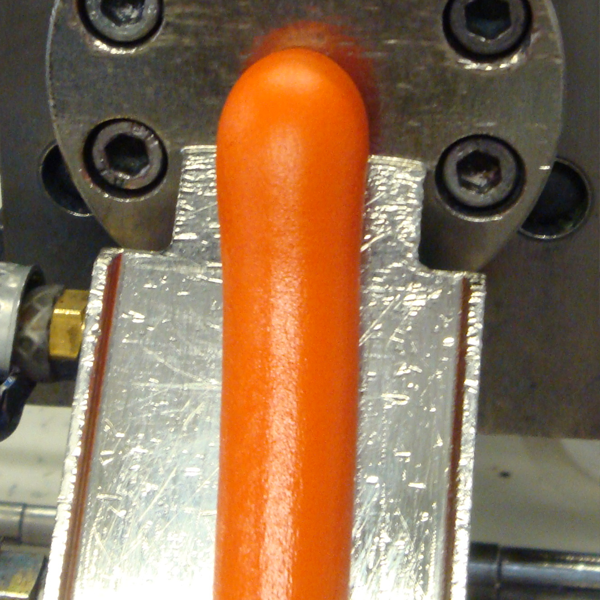

Melt extrusion control of powder coatings

The melt extrusion link of powder coating is an important link in the production process of powder coating. Its purpose is to melt the premixed raw materials into thin flakes, and then cool and grind them. The quality of the melt extrusion process directly affects the fluidity, adhesion, wear resistance and other properties of the powder coating. The control of melting temperature is the key to this process. Too low a melting temperature will cause insufficient melting of raw materials and affect the fluidity and adhesion of the coating. Too high a melting temperature may cause the paint to melt excessively, affecting the wear resistance of the paint. The control of extrusion pressure can ensure that the powder coating can be extruded evenly. Uniform extrusion pressure and speed can effectively ensure the quality and performance of the powder coating. We are equipped with complete online monitoring equipment to monitor the melting temperature, extrusion pressure and other related data of powder coatings in real time to improve data support for process control of the entire production process.

Cooling grinding of powder coatings

The cooling and grinding process of powder coatings is an important link in the production process of powder coatings. Its purpose is to cool the melted extruded flakes into solids, and then crush and grind them to obtain powder coatings. The quality of the cooling and grinding process directly affects the particle size distribution, fluidity, adhesion and other properties of the powder coating. In this process, we focus on controlling the cooling rate and grinding particle size to ensure the quality of the powder coating. Proper cooling rate ensures uniform cooling of the powder coating. If the cooling rate is too fast, the surface temperature of the powder coating will be too low, affecting the adhesion of the coating. If the cooling rate is too slow, the internal temperature of the coating will be too high, affecting the fluidity of the coating.

Packaging and warehousing of powder coatings

The packaging and storage conditions of powder coatings directly affect the performance and storage life of powder coatings. We usually use better-sealed packaging materials to package and store powder coatings to prevent moisture absorption, oxidation and contamination. The most common packaging method for powder coatings is PP bags + cartons. If customers have special packaging needs, we can also provide corresponding packaging services. The finished powder coating will be stored in a dry, ventilated, and cool place away from direct sunlight and high temperatures. The temperature of the storage environment is usually controlled between 5-25°C, and the relative humidity is kept below 50%.

Have Anything To Ask Us?