Pure Polyester VS Epoxy Powder Coating

Coatings are like the unsung heroes of the material world, silently protecting and enhancing surfaces we interact with daily. In the realm of powder coatings, two heavyweights—Pure Polyester and Epoxy—vie for the spotlight. Imagine them as rival superheroes, each with its unique superpowers. Today, we embark on a thrilling journey to uncover the differences, strengths, and real-world applications of Pure Polyester and Epoxy Powder Coatings.

a. Characteristics and Benefits

Pure Polyester Powder Coating is a fascinating coating technology known for its distinctive features and numerous benefits. Let’s take a closer look at what sets it apart:

Exceptional Durability: Pure Polyester Coating is renowned for its exceptional durability, making it an ideal choice for surfaces that face tough conditions. It resists corrosion, weathering, and UV damage, ensuring that coated surfaces remain in top condition for years.

UV Resistance: With UV-blocking properties, Pure Polyester Coating protects against color fading and structural damage caused by exposure to sunlight. This makes it perfect for outdoor applications.

Low VOC Emissions: Pure Polyester Coating emits low levels of Volatile Organic Compounds (VOCs), making it an eco-friendly option that contributes to a cleaner environment.

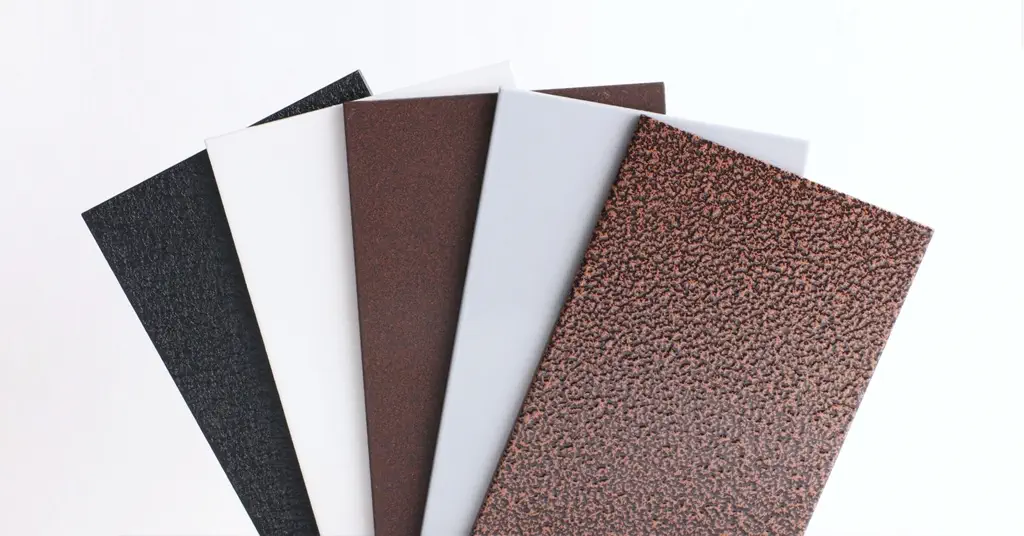

Customization: The coating offers a wide range of colors, textures, and finishes, allowing for customization to meet specific design and aesthetic requirements.

Minimal Hazardous Waste: It generates minimal hazardous waste, thanks to its dry application method, and is easy to reclaim and reuse, reducing environmental impact.

b. Applications and Best Use Cases

Pure Polyester Powder Coating’s versatility shines through in its wide range of applications. Here are some of the best use cases where it excels:

Architectural and Building Use: Pure Polyester Coating is a popular choice in the construction industry, providing long-lasting protection for architectural elements such as window frames, railings, and facades. Its customizable finishes enhance the visual appeal of buildings.

Automotive and Transportation: The automotive industry benefits from the durability and UV resistance of Pure Polyester Coating. It’s used on wheels, chassis components, and more, ensuring both aesthetics and performance.

Furniture and Home Decor: From outdoor furniture to metal bed frames, Pure Polyester Coating protects against weathering, offering vibrant colors and finishes for a wide range of home decor products.

Industrial and Commercial Equipment: Industrial machinery, electrical enclosures, and storage racks benefit from the protective qualities of Pure Polyester Coating. Customization options help maintain a professional appearance.

a. Characteristics and Benefits

Epoxy Powder Coating is a coating technology celebrated for its exceptional properties and a wide array of benefits. Let’s delve into what makes it stand out:

Outstanding Durability: Epoxy Coating is renowned for its remarkable durability, making it a go-to choice for surfaces exposed to harsh conditions. It resists impact, abrasion, and chemicals, ensuring that coated surfaces remain pristine and functional over time.

Corrosion Resistance: Epoxy Coating provides excellent protection against corrosion, making it ideal for surfaces exposed to moisture, salt, and other corrosive substances. It extends the lifespan of the coated materials.

Versatility: Epoxy Coating is highly versatile, available in various formulations to suit different applications. It can be used as a protective and decorative coating on a wide range of substrates.

Aesthetic Appeal: Beyond its protective properties, Epoxy Coating offers an attractive and smooth finish that can enhance the appearance of surfaces. It’s available in a multitude of colors, allowing for customization to meet design requirements.

Chemical Resistance: Epoxy Coating can withstand exposure to a variety of chemicals, making it a preferred choice for laboratories, industrial settings, and more.

b. Applications and Best Use Cases

Epoxy Powder Coating’s versatility is evident in its extensive range of applications. Here are some of the best use cases where it excels:

Industrial and Manufacturing: Epoxy Coating is widely used in industrial and manufacturing settings to protect machinery, equipment, and metal components. Its resistance to corrosion and chemicals ensures long-term performance.

Commercial Flooring: Epoxy Coating is a popular choice for commercial and industrial flooring due to its durability, easy maintenance, and a range of available colors and finishes.

Aerospace and Automotive Industries: Epoxy Coating provides protection and a polished finish to components in the aerospace and automotive sectors, where resilience and aesthetics are crucial.

Healthcare and Laboratories: The chemical resistance of Epoxy Coating makes it a preferred option in healthcare facilities and laboratories, where surfaces must endure exposure to various substances.

3. Key Differences Between Pure Polyester and Epoxy Coating

a. Chemical Composition

Pure Polyester Coating: Pure Polyester coatings are primarily composed of polyester resins and special additives. These coatings are known for their excellent color retention, making them a popular choice for applications where aesthetics matter.

Epoxy Coating: Epoxy coatings, on the other hand, are made from epoxy resins and a curing agent. This combination results in coatings with remarkable adhesion, durability, and resistance to chemicals and corrosion.

b. Durability and Longevity

Pure Polyester Coating: Pure Polyester coatings are highly durable, providing excellent protection against UV radiation and weathering. This makes them an excellent choice for surfaces exposed to sunlight and outdoor elements. However, in terms of abrasion resistance and chemical resistance, they may not match up to epoxy coatings.

Epoxy Coating: Epoxy coatings are known for their superior durability and longevity. They excel in harsh environments where surfaces face heavy use, chemicals, and potential abrasion. This makes them a preferred choice for industrial and commercial applications.

c. UV Resistance

Pure Polyester Coating: Pure Polyester coatings boast excellent UV resistance. They protect surfaces from the harmful effects of prolonged sun exposure and are an ideal choice for outdoor applications. These coatings maintain their color and finish, preventing color fading.

Epoxy Coating: Epoxy coatings may not offer the same level of UV resistance as Pure Polyester. They are better suited for indoor or controlled environments where UV exposure is not a significant concern.

d. Cost Considerations

Pure Polyester Coating: Pure Polyester coatings are often cost-effective, making them an attractive choice for various projects. Their durability and UV resistance add value to the investment.

Epoxy Coating: Epoxy coatings, while offering exceptional performance, can be costlier due to their high durability and specialized applications.

Choosing the right coating technology is crucial for different projects. In this article, we explore in detail the key differences between pure polyester powder coating and epoxy powder coating, including aspects of their chemical composition, durability, UV resistance, environmental impact and cost.

Pure polyester powder coating stands out for its excellent UV resistance, durability suitable for outdoor use and relatively low environmental impact, making it particularly suitable for projects where beauty and protection are emphasized. However, for projects that require superior durability, resistance to chemicals, and heavy use, epoxy powder coating may be more appropriate.

Have Anything To Ask Us?