Pure Polyester Powder Coating for Architectural Use

In the field of construction, the choice of materials is crucial. As technology continues to advance, we now have a superior solution in the form of pure polyester powder coating. This type of powder coating has made a splash in the construction world, providing designers, builders, and homeowners with a durable, environmentally friendly, and attractive option. Whether indoors or out, pure polyester powder coatings demonstrate outstanding performance, making them ideal for a variety of construction projects. Let’s take a deeper look at why this material is so compelling and why it has so many uses in construction.

1. Specific applications of pure polyester powder coatings in the field of website construction

When it comes to architectural applications, pure polyester powder coatings have emerged as a game-changer. Their exceptional properties make them the top choice for various aspects of building design and construction. In this section, we’ll delve into their specific applications, showcasing their remarkable versatility and durability.

a. Coating for Building Exteriors

Facades and Curtain Walls

Pure polyester powder coatings find their stride in enhancing the aesthetics and longevity of building facades and curtain walls. Whether you’re designing a modern skyscraper or a contemporary residence, these coatings provide a protective, weather-resistant, and visually appealing solution. They create a sleek, uniform finish that can withstand harsh environmental conditions while retaining their vibrancy.

Cladding and Panels

For architects and builders looking to achieve both functionality and style, pure polyester powder coatings are the go-to option for cladding and panels. These coatings offer a diverse color palette, allowing for endless design possibilities. They not only protect the building structure from corrosion and UV damage but also contribute to the overall architectural appeal.

b. Railings, Balconies, and Fences

Safety and aesthetics go hand in hand when it comes to railings, balconies, and fences. Pure polyester powder coatings provide a durable and attractive solution for these architectural elements. They ensure that outdoor railings and fences remain rust-free, fade-resistant, and easy to maintain, thereby enhancing the building’s overall appearance.

c. Architectural Details and Ornamental Work

Attention to detail is what sets exceptional architecture apart, and pure polyester powder coatings play a crucial role in preserving the beauty of architectural details and ornamental work. From intricate ironwork to decorative elements, these coatings protect against wear and tear, ensuring that every detail stands the test of time.

d. Outdoor Signage

Effective signage is an integral part of building design, and outdoor signage often faces the harshest weather conditions. Pure polyester powder coatings offer a reliable solution for outdoor signage. They resist fading, chipping, and peeling, ensuring that your building’s signage remains clear and vibrant, even in the most challenging environments.

Pure polyester powder coating is a remarkable choice for architectural applications due to its numerous benefits. In this section, we will explore the specific advantages that make these coatings stand out in the construction industry, demonstrating their practicality and long-lasting value.

a. Durability and Longevity

When it comes to architectural projects, durability is a top priority. Pure polyester powder coatings excel in this aspect, offering an exceptional lifespan for building components. These coatings form a robust barrier against corrosion and environmental wear and tear, ensuring that your structures remain structurally sound and visually appealing for years to come. Whether it’s exterior facades or ornamental work, their durability guarantees a lower need for repairs and replacements, saving both time and money in the long run.

Architectural elements exposed to sunlight often suffer from color fading and degradation. However, pure polyester powder coatings have an inherent resistance to UV rays. This means that the vibrant colors and finishes applied to your building’s exterior, signage, railings, and more will remain vivid and intact, maintaining the aesthetic appeal of your architectural design. You won’t have to worry about your building’s appearance being compromised over time.

c. Minimal Maintenance

Architects and property owners appreciate the low maintenance requirements of pure polyester powder coatings. Unlike traditional paint or finishes that may require frequent touch-ups and repainting, these coatings demand minimal maintenance. Their resistance to chipping, peeling, and corrosion ensures that your architectural elements continue to look pristine with little effort. This ease of maintenance not only reduces ongoing costs but also contributes to the sustainability of the building.

d. Environmental Benefits

In an era of increasing environmental consciousness, the use of pure polyester powder coatings aligns with sustainable architectural practices. These coatings are eco-friendly and comply with stringent environmental standards. They release minimal or no volatile organic compounds (VOCs), reducing air pollution and promoting a healthier indoor and outdoor environment. Furthermore, the process of applying these coatings generates minimal waste, making them an environmentally responsible choice.

3. Surface Preparation in Architectural Projects

Surface preparation is a critical step in architectural projects that sets the foundation for a successful coating process. In this section, we will delve into the importance of surface preparation, the specific steps involved, and how it ensures the longevity and quality of coatings in architectural applications.

a. Cleaning and Contaminant Removal

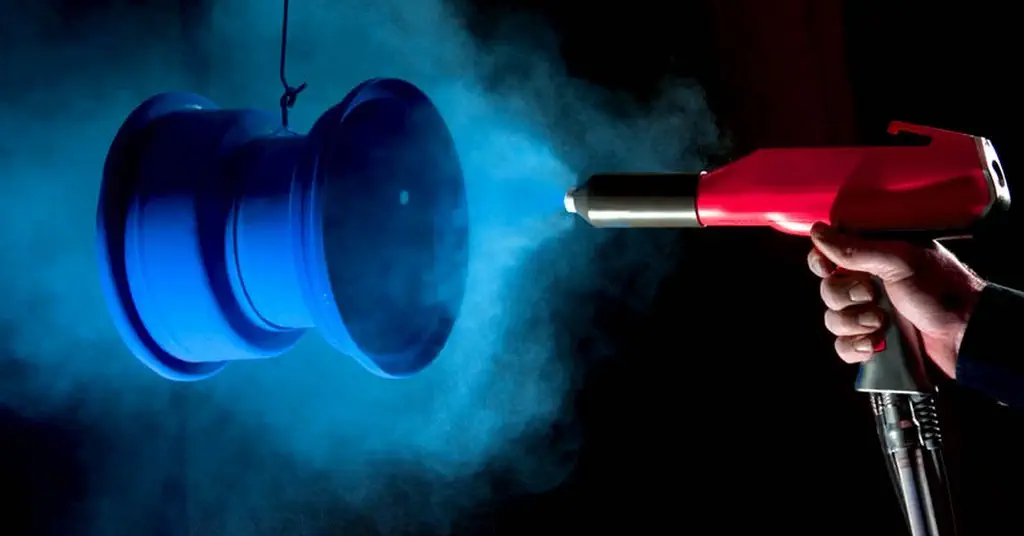

Effective surface preparation begins with thorough cleaning and contaminant removal. This step is essential to eliminate any dirt, grease, oil, or other impurities that may hinder the adhesion of coatings. Whether you’re working on exterior facades, railings, or decorative elements, a clean surface is non-negotiable. Techniques such as power washing, chemical cleaning, or abrasive cleaning are employed to ensure the removal of unwanted substances.

b. Surface Profiling and Inspection

To create a receptive surface for coatings, surface profiling is the next crucial step. It involves the removal of any loose, deteriorated materials and the establishment of an ideal surface profile for coating adhesion. Surface profiling methods vary based on the substrate and coating type. After profiling, a thorough inspection is conducted to identify any imperfections, rust, or damage that must be addressed before the coating application begins.

c. Preparing for the Coating Process

Proper surface preparation also entails selecting the appropriate coating system and ensuring compatibility with the substrate. This step involves choosing the right coating materials, primers, and topcoats, considering factors such as environmental conditions, UV exposure, and required durability. Additionally, proper masking and protection of adjacent areas are crucial to prevent overspray and ensure a clean and professional finish.

Pure polyester powder coatings are increasingly recognized for their use in the construction field. Super durability and extremely long service life greatly reduce the overall cost of construction. Excellent color durability and UV resistance allow construction projects to maintain their best condition for a long time. Pure polyester powder is used on a large scale as the preferred decorative protective material for building exterior facades, railings, balconies and related building decoration projects. However, when using pure polyester powder in the construction field, the coating surface needs to be optimized to avoid burrs, pits and other defects that affect the overall spraying effect.

Have Anything To Ask Us?