Powder Coating Gun Maintenance Tips

Do you know what parts need to be inspected every week when maintaining your powder spray gun? What do you need to do when you encounter equipment failure when using a powder coating gun? As one of the most important pieces of equipment in the powder coating process, the maintenance of powder coating guns requires specific and corresponding expertise. This article provides you with professional and reliable maintenance suggestions through analysis of common faults of powder coating guns. These maintenance tips can help extend the life of your powder coating gun.

1. Daily Maintenance

Daily maintenance is the bedrock of peak performance in the world of powder coating. A disciplined routine ensures that your powder coating gun operates at optimal efficiency every day.

a. Cleaning the powder coating gun body and components

Regularly cleaning the gun body and its components is not just about aesthetics; it’s a fundamental step in maintaining consistent coating quality. Dust, residue, or contaminants can compromise the precision of your application. By diligently cleaning every nook and cranny, you safeguard the integrity of your coatings and enhance the overall performance of the powder coating gun.

b. Checking and Cleaning the Powder Hopper

The powder hopper is the reservoir of your operation, and its condition directly influences the application process. Daily checks ensure that the powder hopper is free from any contaminants or blockages that could jeopardize the coating quality. By keeping it clean and well-maintained, you optimize the powder flow, contributing to a seamless and efficient powder coating process.

c. Inspecting the Electrostatic Components

The electrostatic components play a pivotal role in the powder coating process. Regular inspections guarantee that these components are in pristine condition, maintaining optimal electrostatic charge. Any deviation from the desired state can affect coating adhesion and uniformity. By identifying and addressing potential issues proactively, you uphold the reliability of the electrostatic system, ensuring consistent and high-quality coatings.

d. Lubricating Moving Parts

Smooth operation hinges on well-lubricated moving parts. Daily lubrication of critical components ensures that the powder coating gun functions with minimal friction and wear. This not only contributes to the immediate efficiency of the equipment but also extends the lifespan of moving parts, reducing the likelihood of unexpected breakdowns and associated downtime.

2. Weekly Maintenance

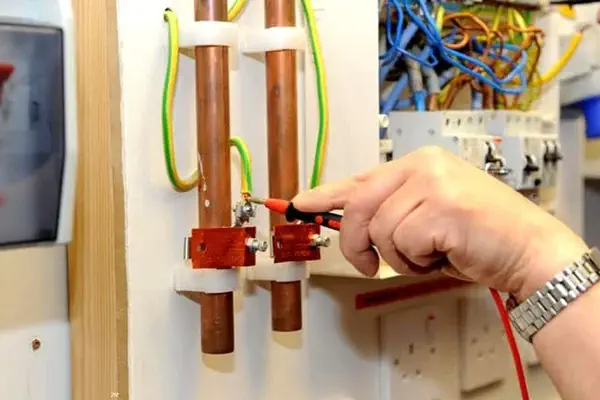

a. Inspection of Electrical Connections

The heartbeat of your powder coating setup lies in its electrical connections. Regular weekly inspections are paramount to identify any loose connections, frayed wires, or potential electrical issues. Addressing these issues proactively prevents disruptions in the electrostatic system, safeguarding the precision and reliability of your powder coating gun.

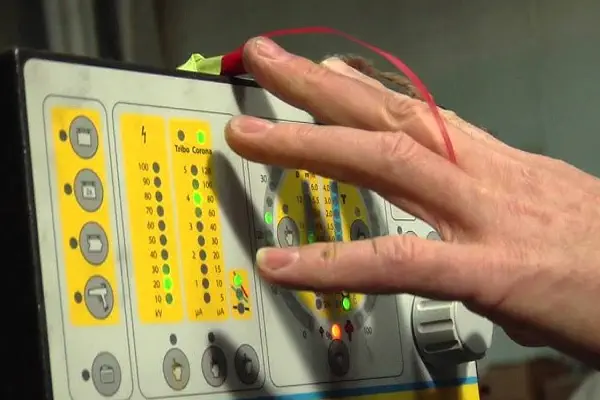

b. Testing and Calibrating Settings

Precision is the essence of quality coating. Weekly testing and calibration of settings ensure that your powder coating gun adheres to the exact specifications required for each application. This meticulous approach guarantees consistent and accurate coating thickness, contributing to the overall quality of your finished products.

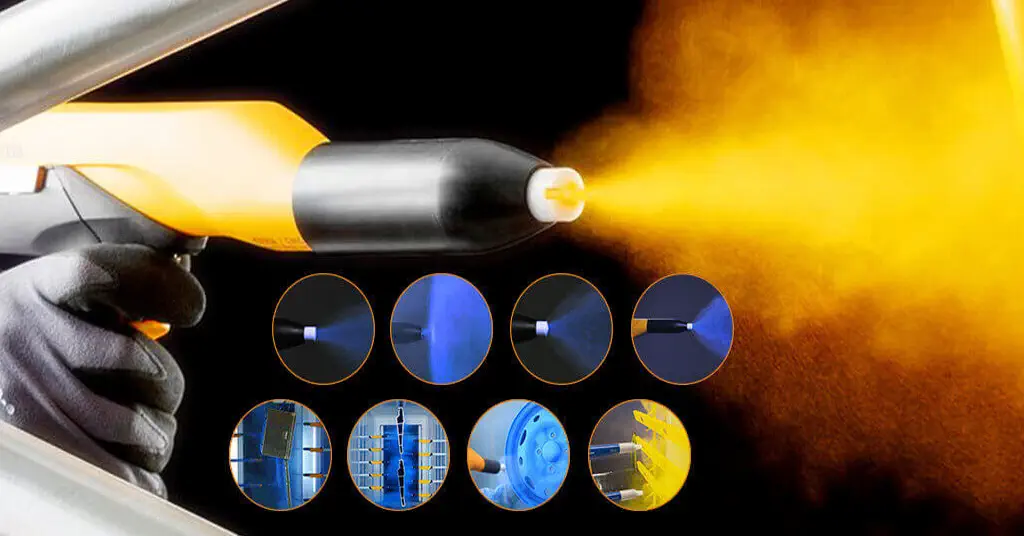

c. Cleaning and Inspecting the Nozzle and Applicator

The nozzle and applicator are the frontline soldiers in the coating process. Weekly cleaning and inspection remove any accumulated powder residue or potential blockages, preventing uneven spray patterns. This attention to detail maintains the integrity of the coating application, ensuring a smooth and flawless finish.

d. Ensuring Grounding Continuity

Grounding is the silent protector against electrostatic discharge mishaps. Weekly checks confirm the continuity of the grounding system. Ensuring that this crucial safety feature is operational prevents potential hazards and maintains the reliability of the electrostatic components in your powder coating gun.

e. Addressing Wear and Tear

Every piece of equipment endures wear and tear over time. Weekly maintenance involves a thorough assessment of wear-prone components. By identifying and addressing signs of wear promptly, you mitigate the risk of unexpected breakdowns. This proactive approach contributes to the overall longevity of your powder coating gun.

3. Troubleshooting and Problem Solving

When encountering various problems when using a powder coating gun, having a thorough understanding of the possible causes and taking appropriate solutions is the key to ensuring a good coating. Here’s a more in-depth expansion of frequently asked questions and detailed solutions.

a. Uneven coating

Possible causes: Nozzle clogging may be caused by powder moisture that is too high or too low. Charge failure can be caused by powder buildup around the nozzle. Unstable air pressure may be due to problems with the compressed air system.

Solution: Clean the nozzles to eliminate blockages, control the moisture content of the powder, clean the surrounding area regularly, ensure the charger is functioning properly, and repair the compressed air system.

b. The coating appears to drip or sag

Possible reasons: Excessive air pressure may cause the powder particles to be too large, incorrect adjustment of the nozzle may cause uneven spraying, and excessive powder coating may cause dripping.

Solution: Adjust the air pressure to ensure moderate powder particle size, adjust the nozzle correctly to achieve even spraying, and reduce the amount of powder coating.

c. The powder does not adhere to the workpiece

Possible reasons: The surface of the workpiece may be affected by oil or oxidation, the charge fails, or there is a problem with the nozzle.

Solution: Clean the workpiece surface before coating, ensure the charging mechanism is functioning properly, and check and clean the nozzle.

d. Inconsistent color or spots

Possible reasons: The powder coating may be uneven, electrostatic failure may cause uneven powder adhesion, and unstable air flow may cause a decrease in coating quality.

Solution: Check coating status and ensure even mixing, adjust charge to keep powder adhering evenly, optimize airflow system to ensure stability.

e. Overspray causes uneven coating thickness

Possible reasons: The operator’s movements may be uneven and the spraying distance may be inappropriate.

Solution: Provide training to operators to maintain uniform action and adjust spray distance to ensure even coating.

f. Charge failure or gun not working

Possible causes: Power failure may be caused by a damaged power cable or poor connection, and the electrodes may be damaged or corroded.

Solution: Check the power cable to ensure a tight connection and repair or replace damaged electrodes.

g. Excessive noise

Possible causes: The nozzle may be clogged, and abnormal air flow may be caused by a problem with the compressed air system.

Solution: Clean or replace clogged nozzles, maintain or repair the compressed air system.

Through routine inspection and maintenance, you can know whether the powder coating gun is working properly. When encountering problems with the powder spray gun, we need to check one by one whether each component of the powder spray gun and related supporting equipment can work normally. It is best to have the support of professional technicians for troubleshooting of professional links such as electrical auxiliary equipment, charge generation equipment, and system control units. Regular maintenance and inspection work can also effectively extend the service life of the powder coating gun.

Have Anything To Ask Us?