Powder Coating 101: Mastering the Pure Polyester powder Process

Powder coating, a transformative technique used in various industries, plays a vital role in protecting and enhancing surfaces. In this blog, we will focus on the preparation and application process of Pure Polyester Powder Coating. Understanding the core aspects of this coating method is essential for both newcomers and seasoned professionals, as it offers durability and aesthetics in a wide range of applications. Let’s delve into the science and artistry of this process.

1. The Composition of Pure Polyester Powder Coating

Pure Polyester Powder Coating is renowned for its unique composition that combines various elements to create a robust and versatile protective layer. In this section, we will delve into the specific components that make up this coating, providing you with a comprehensive understanding of its formulation and properties.

a. Understanding Polyester Resins

At the heart of Pure Polyester Powder Coating lies the polyester resin. These resins are synthesized through the condensation polymerization of various chemical compounds. They offer exceptional durability and resistance to environmental stressors. When combined with curing agents and pigments, polyester resins create a strong and flexible protective film.

b. Other Key Ingredients

In addition to polyester resins, Pure Polyester Powder Coating incorporates several other essential ingredients. These may include curing agents, flow additives, leveling agents, and degassing agents. Each component plays a specific role in the coating’s performance, ensuring proper adhesion, smooth finish, and efficient curing.

c. Powder Formulation

The formulation of Pure Polyester Powder Coating involves a meticulous process of blending the components into a fine powder. This powder is then applied to the surface to be coated. The formulation process is critical as it determines the coating’s adhesion, thickness, and overall quality. It’s a precise science that, when executed correctly, results in a coating that excels in both protection and aesthetics.

2. Surface Preparation

In the world of Pure Polyester Powder Coating, surface preparation stands as a crucial initial step, significantly impacting the coating’s quality and performance. Let’s delve into the specifics of why it’s so essential and how it’s achieved.

a. Importance of Proper Surface Cleaning

Before applying Pure Polyester Powder Coating, ensuring the surface is clean and free from any contaminants is paramount. Whether it’s metal, plastic, or wood, a pristine surface is essential for achieving optimal adhesion and an impeccable finish. Proper surface cleaning removes any dirt, grease, or previous coatings that may hinder the coating’s ability to bond effectively.

b. Removal of Contaminants

Contaminants, such as rust, oils, or old paint, can compromise the coating’s integrity. To address this, surface preparation involves removing these impurities through various techniques. For example, abrasive methods like sandblasting or chemical treatments are employed to eliminate rust and contaminants, leaving a clean canvas ready for coating.

c. Achieving Optimal Adhesion

The key objective of surface preparation is to create a surface that allows the Pure Polyester Powder Coating to adhere effectively. Without proper adhesion, the coating may peel or wear prematurely. Achieving optimal adhesion ensures that the coating remains in place, providing long-lasting protection and a flawless finish.

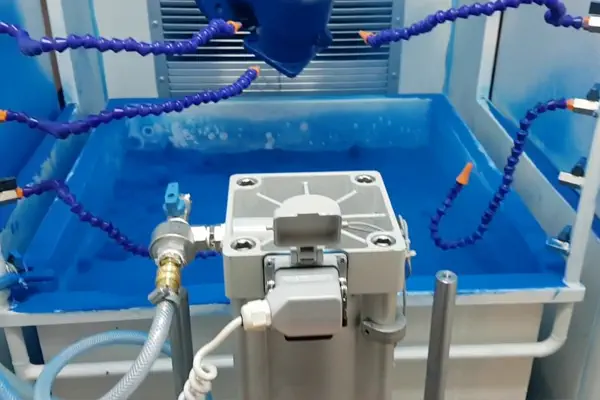

3. Application Methods

The versatility of Pure Polyester Powder Coating lies not only in its composition but also in the various application methods used. In this section, we’ll explore the different techniques employed to apply Pure Polyester Powder Coating and the advantages and disadvantages of each method.

a. Electrostatic Spray

Electrostatic spray is one of the most commonly used methods for applying Pure Polyester Powder Coating. In this process, the powder is electrostatically charged, creating a strong attraction to the grounded substrate. This results in a uniform and even coating that adheres to complex shapes and surfaces. The advantages of electrostatic spray include precise control, minimal waste, and high transfer efficiency. However, it may require specialized equipment and entail additional setup and maintenance costs.

b. Fluidized Bed Coating

Fluidized bed coating involves immersing preheated objects into a fluidized bed of Pure Polyester Powder Coating. The heat causes the powder to melt and adhere to the substrate. This method is well-suited for coating objects with a consistent, evenly distributed layer. It’s a highly efficient process that requires no electrostatic charge, making it a cost-effective solution for some applications. However, it may not be suitable for intricate or detailed workpieces.

c. Triboelectric Charging

Triboelectric charging is an alternative to electrostatic spray. It involves charging the powder particles through friction before applying them to the substrate. This method offers good control over the coating thickness and is especially suitable for applications where precise film thickness is essential. While it may not be as efficient as electrostatic spray, it has the advantage of lower equipment costs and simpler operation.

4. Curing the Coating

Curing is the critical step in the Pure Polyester Powder Coating process that transforms the applied powder into a durable and protective finish. This section will provide insights into the curing process, temperature and time considerations, achieving full cure and adhesion, and the essential role of ovens.

a. Baking Process

Curing is primarily accomplished through a baking process, where the coated objects are subjected to elevated temperatures. During this phase, the powder particles melt and fuse together, forming a continuous film. The baking process is vital to ensure the coating’s integrity and durability.

b. Temperature and Time Considerations

The selection of the right temperature and time parameters is crucial for achieving the desired curing results. The temperature should be carefully controlled to allow the powder to flow and then solidify without overbaking, which could lead to defects. The time factor is equally significant, as it determines how long the object should be exposed to the specified temperature.

c. Achieving Full Cure and Adhesion

Full cure and adhesion are essential for the coating’s performance. Full cure ensures that the coating has reached its maximum hardness and chemical resistance. Proper adhesion guarantees that the coating remains firmly attached to the substrate. Both factors are achieved by closely monitoring and controlling the curing process.

Pure Polyester Powder Coating is a versatile, durable, and precise solution. Proper surface preparation ensures strong adhesion, while various application methods offer flexibility. Curing through baking, temperature control, and time considerations guarantees hardness and chemical resistance, with ovens playing a pivotal role.

In the world of coatings, attention to detail, precise application, and rigorous quality control make Pure Polyester Powder Coating a trusted option. Whether it’s durability, aesthetics, or protection, this coating consistently delivers exceptional results.

5. Durability and ease of maintenance

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?