Indonesia Puooke Electrical Appliance Company’s Powder Coating Purchasing Case

Customer Profile

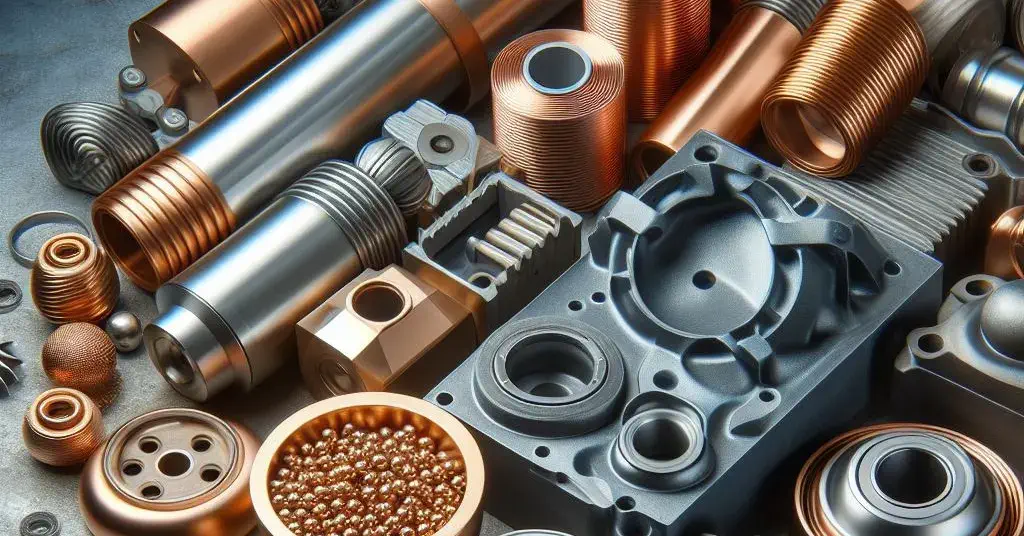

Puooke Electrical Appliance Company of Indonesia is a well-known electronic component manufacturing company in Jakarta. It has many years of rich experience in the field of electronic components and small household appliances. The company focuses on manufacturing circuit boards, simple chips, connectors and other electronic components, and has maintained a leading position in the Indonesian market. As the market continues to develop, they are also trying to sell finished products in the field of home appliances instead of just providing OEM services for other home appliance brands. Recently, Puooke Electric Co., Ltd. is preparing to improve the surface coating technology of its electronic components and the shell coating of household appliances to enhance the corrosion resistance and exterior light quality of the products.

Process of cooperation

Previously, we had not established a partnership with Indonesian Puooke Company. We only had simple communication at the 2020 Shanghai Chemical Industry Expo. From 2020 to 2022, due to the impact of the epidemic, the two parties only maintained simple business communication. Until April 2023, we received an inquiry from Puooke Company. They were interested in a polyester powder coating displayed on our website and hoped that we would provide more detailed product performance parameters and quotations.

In fact, there are many different types of powder coatings that can be used in electronic components. Epoxy resin powder coatings, polyester resin powder coatings, polyetherketone powder coatings, fluoropolymer powder coatings and polyethylene terephthalate powder coatings are widely used in the field of electronic component coating.

After conducting in-depth research with domestic automotive research institutions, our technical team configured 3 different proportions of automotive engine coating powder coatings. The additives, curing agents and main components of these three powder coatings are similar, but their anti-corrosion, high temperature resistance and wear resistance properties are quite different after specific electrostatic spraying and melt solidification processes. Considering that engines of different models have completely different usage environments and working conditions, these three powder coatings can meet the engine coating design needs of Yadong Company to a large extent.

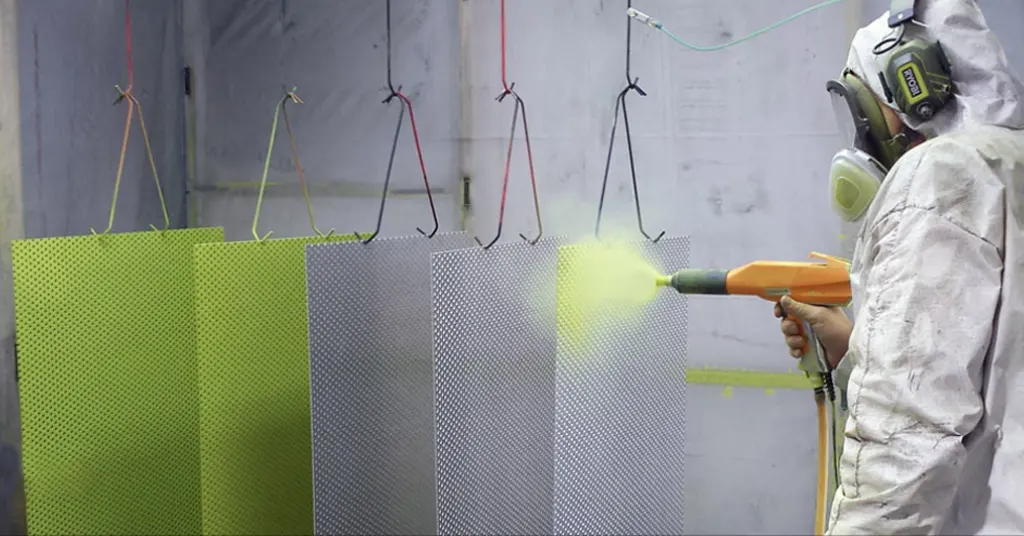

Given the most suitable type of powder coating for Puooke Electrical Appliance Company to purchase, our technical R&D team conducted in-depth discussions with its relevant person in charge. We have in-depth communication about the specific uses of powder coatings in the field of electronic components, and the needs that their company wants to achieve in terms of anti-corrosion, wear resistance, and color brightness protection. Finally, through communication between the two parties, we discussed a more cost-effective powder coating application plan. This solution still uses polyester epoxy powder coating as the main body, but the difference is that the ratio of additives and fillers is changed to achieve better insulation, anti-corrosion and appearance color protection effects. In addition, this solution consumes less energy during actual operation. It uses less energy and can reduce costs for enterprises’ mass manufacturing to a greater extent.

After rigorous testing and verification, the performance of the new polyester powder coating we provided has met the customers’ stringent design specifications. The director of the technical development department of the Indonesian Puooke Company wrote a special email to express his gratitude for our meticulous work and professional services and actively promoted the cooperation process between the two parties.

Have Anything To Ask Us?