How to choose a powder coating equipment supplier?

As a powder coating practitioner, you definitely want to purchase powder coating equipment with stable quality, advanced functions and competitive price. So how to choose a suitable powder coating equipment supplier to purchase the powder coating equipment of your choice is definitely a question you want to know urgently. This article will give you an in-depth understanding of 10 factors that need to be carefully considered when choosing a powder coating equipment supplier.

1. Supplier qualification inspection

Suppliers with a good reputation in the field of powder coating equipment should be your first choice. Only by providing excellent powder coating equipment and high-quality services over many years of history can these companies gain a good reputation in the industry. We recommend that you contact the manufacturer of your powder coating equipment directly, bypassing the intermediary agent. This can save you a lot of intermediate purchasing costs. In addition, you can customize the spraying function in more detail according to your actual powder coating needs. Taking a powder coating oven as an example, you can communicate with the factory to meet your special needs, such as baking temperature rise curve settings.

2. Relevant parameters of powder coating equipment

The size of the workpiece and equipment to be coated, as well as the daily manufacturing rate, largely determine the parameters related to the powder coating equipment you need. The large equipment to be sprayed is obviously unable to complete the melting and solidification process of the powder coating in a small-sized oven. In addition, the energy consumption loss of powder coating equipment is also a problem that cannot be ignored. A large amount of heat will be lost during the baking process of powder coating, so you need a powder coating baking oven with better thermal insulation performance. An oven with 5-inch walls will provide better insulation than an oven with 3-inch walls, saving you a lot of money in the long run.

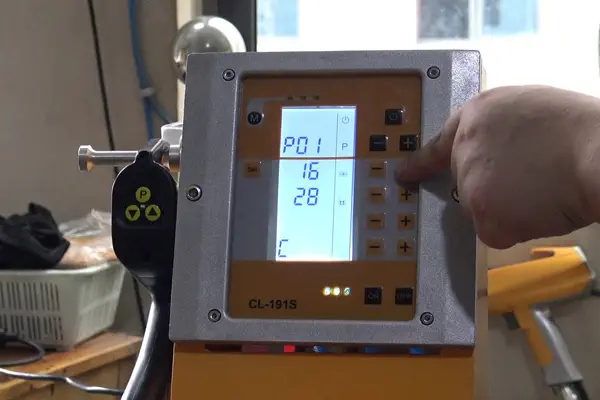

3. Whether to support after-sales service

Many small powder coating equipment companies do not provide corresponding after-sales services, which can save their business operating costs as much as possible. However, not every company or individual purchasing powder coating equipment has sufficient professional knowledge and skills to handle corresponding equipment failures and problems. Taking the curing oven of powder coating as an example, professionals need to perform calibration services before using the equipment to ensure safe and efficient operation of the equipment for a long time. If you are a large-scale powder coating server, you should choose a company that supports after-sales service.

4. Whether there is a professional technical team

In the process of using powder coating equipment, you will definitely encounter various malfunctions. Unless you are an expert in equipment manufacturing or you happen to have relevant spare parts to replace, it is difficult to completely solve the problem of powder coating failure. When you choose a powder coating equipment supplier, you should ask in detail whether the other party has a professional and senior technical team. What specific troubleshooting services can these technical teams provide you with? Whether it is simple telephone communication, video communication, or a technical team can arrive at the scene in time to provide you with troubleshooting services.

5. Is it convenient to replace the equipment’s wearing parts?

When powder coating equipment fails to work properly due to damaged parts during use, it is a very important consideration to be able to obtain replacement parts as soon as possible. Specially customized spare parts are unlikely to be kept in stock. If the supplier requires additional customization, it will waste a lot of your working time. When choosing a supplier of powder coating equipment, you need to ask whether they have sufficient inventory of equipment parts. If not, are there any other solutions? If consumable parts for powder coating equipment can be purchased in the local market, will these spare parts perfectly match the existing powder coating equipment?

6. How to choose between new equipment and second-hand equipment

With the budget available, it’s obvious that you should opt for brand new powder coating equipment. But this ideal situation is not available in every powder coating studio. In most cases, small or start-up powder coating companies face the problem of financial constraints. So how to choose between second-hand powder coating equipment and brand-new equipment? Without professional experience with powder coating equipment, you should carefully consult the manufacturer about the current condition of the used equipment. Can second-hand powder coating equipment still provide stable performance or are there certain deficiencies that require additional improvements? Will the cost of these potential improvements and potential future troubleshooting outweigh the purchase of a brand-new powder coating equipment? After comprehensively evaluating the used and new equipment mentioned above, you should have a definite answer.

7. Warranty Agreement for Powder Coating Equipment

Warranty services vary widely among powder coating equipment suppliers. Big brand painting equipment suppliers may have service agents in your local area who can provide you with better after-sales service, so the warranty time can be appropriately extended. Some small powder coating equipment manufacturers may not be able to provide customers with long warranty services due to cost considerations. But when your powder coating equipment encounters a failure, you may receive completely different warranty services, which means that you may face the problem of solving the powder coating equipment failure for free or at your own expense.

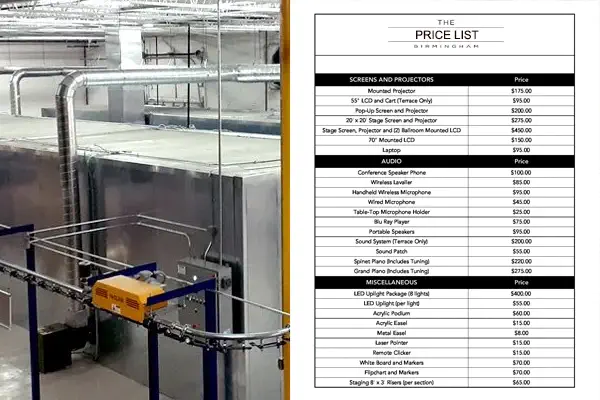

8. Price of powder coating equipment

Price is always a key factor in deciding whether to purchase a certain powder coating equipment. A price that is too high is definitely something you are not willing to face. But that doesn’t mean you should give up purchasing this type of powder coating equipment because of the high price. Factors such as product performance, comprehensive services, brand premium, technical support and shipping costs together constitute the final price of powder coating equipment. You should make a list of several different brands of powder coating equipment to compare and choose the one that is truly high quality and affordable.

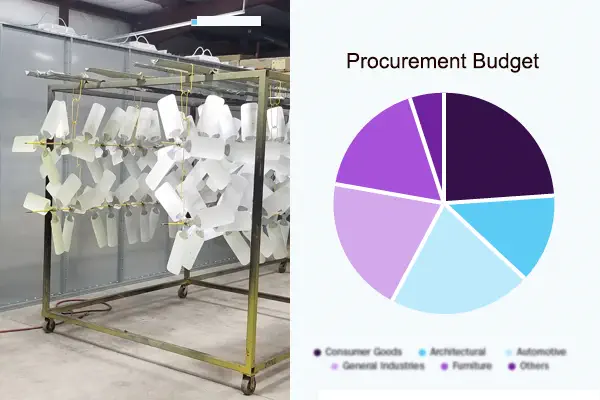

9. Investment budget for powder coating equipment

The investment budget for powder coating equipment directly determines what kind of powder coating equipment you will purchase. When budget is not limited, new multifunctional powder coating equipment is your first choice. But it does not mean that the more expensive the powder coating equipment, the better. You need to fully examine the cost-effectiveness of the powder coating equipment. Make comprehensive considerations within the overall budget and reserve as much funds as possible for future powder coating equipment operations. This part of the reserved funds can help you purchase accessories or hire professional maintenance personnel when you face powder coating equipment failure.

10. Timeliness of delivery

If the powder coating supplier cannot deliver the goods in time, then no matter how cheap their powder coating equipment is and how excellent its performance, you cannot choose to cooperate with them. On-time delivery of powder coating equipment ensures that your powder coating work is produced on time and in an orderly manner. Untimely delivery may also result in the risk of price changes and increased freight costs. You can purchase powder coating equipment in advance to avoid delivery delays or stipulate in the contract terms that you will be compensated for late delivery.

The above ten points are the priorities that should be considered when choosing a powder coating equipment supplier. Choosing the right powder coating equipment manufacturer can reduce unnecessary troubles for your powder coating work and reduce potential expenses in the future. As a powder coating R&D and manufacturer, Ucoat has decades of professional experience in the field of powder coatings. Any related questions about powder coating can contact us, we will provide you with free powder coating samples and proper powder coating solutions.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?