Epoxy Powder Coating in the Construction Industry: Strength and Style Combined

In the construction industry, durability and aesthetics are paramount. Metal surfaces, whether structural or decorative, require protection against environmental factors while maintaining an appealing appearance. Epoxy powder coating has emerged as a leading solution, combining strength and style to meet the demanding needs of modern construction projects. This article delves into the advantages of epoxy powder coating and its applications in the construction sector.

What is Epoxy Powder Coating?

Epoxy powder coating is a dry finishing process where a fine powder is applied electrostatically to a metal surface. The coated surface is then cured under heat, forming a hard, protective layer. This method offers superior durability, corrosion resistance, and a wide range of aesthetic options compared to traditional liquid paints.

Key Benefits of Epoxy Powder Coating in Construction

- Exceptional Durability: Epoxy coatings provide a robust barrier against physical wear and tear, making them ideal for high-traffic areas and structural components.

- Corrosion Resistance: Metal surfaces in construction are often exposed to moisture, chemicals, and other corrosive elements. Epoxy powder coatings offer excellent protection against rust and corrosion.

- Aesthetic Versatility: Available in a variety of colors, textures, and finishes, epoxy powder coatings can enhance the visual appeal of architectural elements, fixtures, and structural components.

- Environmental Sustainability: The powder coating process emits minimal volatile organic compounds (VOCs), making it an eco-friendly choice for sustainable construction practices.

Applications of Epoxy Powder Coating in Construction

1. Structural Steel

Structural steel components, such as beams, columns, and trusses, are critical to the integrity of buildings and infrastructure. Epoxy powder coatings protect these elements from corrosion and environmental damage, ensuring long-term stability and safety.

2. Architectural Metalwork

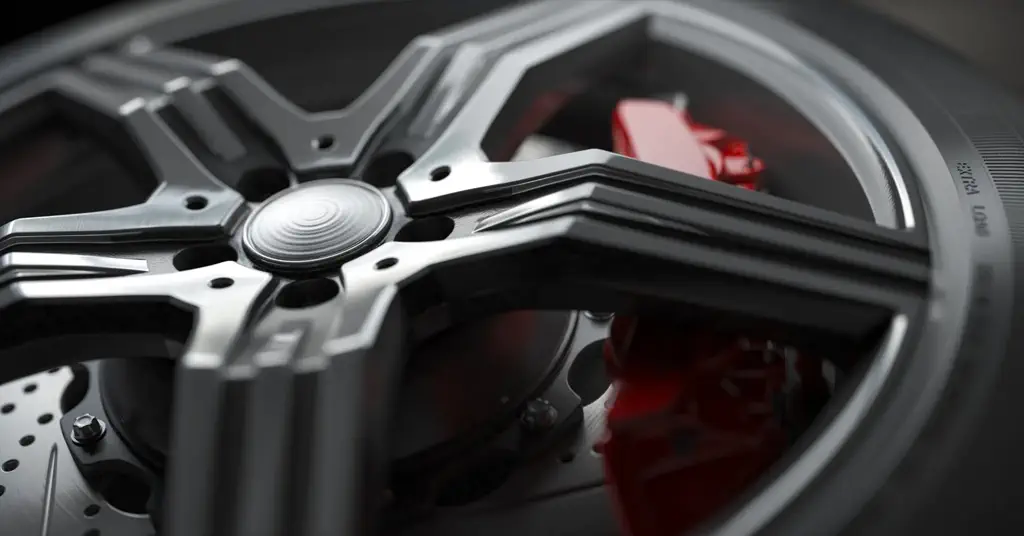

From handrails and balustrades to façades and decorative panels, architectural metalwork benefits from the durability and aesthetic flexibility of epoxy powder coatings. The ability to achieve various finishes, including matte, gloss, and textured, allows designers to create visually striking elements.

3. HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems often involve metal ducts and components exposed to varying temperatures and humidity levels. Epoxy powder coatings provide a protective barrier that enhances the longevity and performance of these systems.

4. Bridges and Infrastructure

Bridges, overpasses, and other infrastructure projects require coatings that can withstand harsh environmental conditions, including UV exposure, saltwater, and pollution. Epoxy powder coatings offer superior protection, reducing maintenance costs and extending the lifespan of these structures.

5. Interior Fixtures and Fittings

In commercial and residential buildings, interior fixtures such as light fixtures, door handles, and furniture benefit from the durability and aesthetic appeal of epoxy powder coatings. The wide range of available colors and finishes allows for customization to match interior design themes.

Factors to Consider When Using Epoxy Powder Coating in Construction

1. Surface Preparation

Proper surface preparation is essential for achieving optimal adhesion and performance. Techniques such as sandblasting, chemical cleaning, and phosphating ensure the metal surface is free from contaminants and ready for coating.

2. Environmental Conditions

Consider the specific environmental conditions the coated surfaces will face. For outdoor applications, choose coatings with UV resistance to prevent fading and degradation. For areas exposed to chemicals or high humidity, select coatings with enhanced chemical and moisture resistance.

3. Application Methods

The choice of application method can impact the quality and efficiency of the coating process. Common methods include electrostatic spray, fluidized bed, and electrostatic fluidized bed. Each method has its advantages and is suited to different types of projects and components.

4. Curing Process

The curing process is critical to the performance of the epoxy powder coating. Ensure the appropriate curing temperature and time are maintained to achieve a durable and uniform finish. Proper curing also enhances the coating’s resistance to chipping, scratching, and corrosion.

5. Compliance and Standards

Ensure the epoxy powder coating complies with relevant industry standards and certifications. This is particularly important for construction projects that must meet specific regulatory requirements, such as fire resistance, chemical resistance, and environmental impact.

Conclusion

Epoxy powder coating is a versatile and effective solution for protecting and enhancing metal surfaces in the construction industry. Its combination of strength, durability, and aesthetic appeal makes it an ideal choice for a wide range of applications, from structural steel to architectural metalwork. By considering factors such as surface preparation, environmental conditions, and application methods, construction professionals can achieve optimal results and ensure the longevity and performance of their projects.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?