Common Mistakes to Avoid When Using Epoxy Powder Coating

Epoxy powder coating is a highly effective and versatile finishing method, but achieving the best results requires attention to detail and proper technique. Even small mistakes can compromise the durability, appearance, and performance of the coating. In this article, we’ll explore the most common mistakes to avoid when using epoxy powder coating and provide practical tips to ensure a flawless finish.

1. Inadequate Surface Preparation

Mistake: Skipping or rushing through surface preparation.

Why It’s a Problem: Any dirt, grease, rust, or old paint left on the surface can prevent the powder from adhering properly, leading to poor adhesion, bubbles, or peeling.

How to Avoid It:

Thoroughly clean the surface using degreasers or chemical treatments.

Remove rust and old paint with sandblasting or abrasive techniques.

Ensure the surface is completely dry before applying the powder.

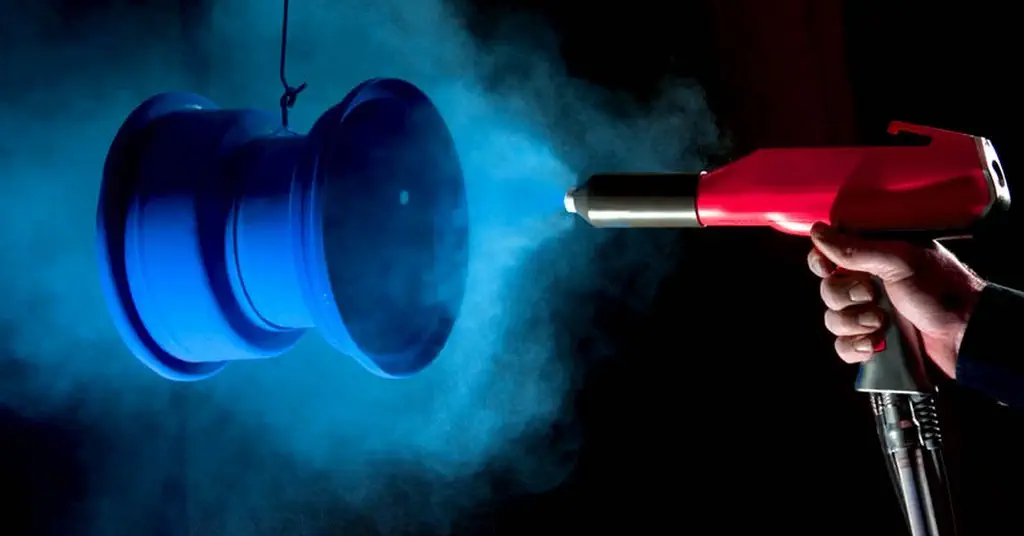

2. Incorrect Powder Coating Application

Mistake: Applying the powder unevenly or too thickly.

Why It’s a Problem: Uneven application can result in thin spots that are prone to corrosion or thick areas that may not cure properly.

How to Avoid It:

Use an electrostatic spray gun for even coverage.

Maintain the correct distance and angle while spraying.

Apply multiple thin layers rather than one thick coat.

3. Ignoring Environmental Conditions

Mistake: Applying powder in a dusty, humid, or poorly ventilated environment.

Why It’s a Problem: Dust or moisture can contaminate the powder, leading to imperfections like pinholes or orange peel texture.

How to Avoid It:

Work in a clean, dry, and well-ventilated area.

Control humidity levels to prevent moisture from affecting the powder.

Use air filtration systems to minimize dust.

4. Incorrect Curing Temperature and Time

Mistake: Over-curing or under-curing the coating.

Why It’s a Problem: Under-curing can result in a weak finish that chips or peels, while over-curing can cause discoloration or brittleness.

How to Avoid It:

Follow the manufacturer’s recommended curing temperature and time.

Use an oven thermometer to ensure accurate temperature control.

Monitor the curing process closely to avoid deviations.

5. Using the Wrong Type of Powder

Mistake: Choosing an epoxy powder formula that doesn’t suit the application.

Why It’s a Problem: Different environments and uses require specific properties, such as UV resistance, chemical resistance, or high-temperature tolerance.

How to Avoid It:

Select a powder formula tailored to your specific needs.

Consult with suppliers or experts to determine the best product for your project.

Test the powder on a small area before full-scale application.

6. Poor Grounding During Electrostatic Application

Mistake: Failing to properly ground the object being coated.

Why It’s a Problem: Inadequate grounding reduces the electrostatic charge, leading to poor powder adhesion and uneven coverage.

How to Avoid It:

Ensure the object is properly grounded before applying the powder.

Use grounding straps or clips to maintain a strong connection.

Check for any interruptions in the grounding circuit.

7. Neglecting Quality Control

Mistake: Skipping post-application inspections.

Why It’s a Problem: Defects like thin spots, bubbles, or contamination may go unnoticed, compromising the coating’s performance.

How to Avoid It:

Inspect the coated surface for consistency, thickness, and adhesion.

Use tools like thickness gauges to measure the coating’s uniformity.

Address any defects before the coating fully cures.

8. Overlooking Safety Precautions

Mistake: Ignoring safety measures during application and curing.

Why It’s a Problem: Epoxy powder coating involves high temperatures and chemicals, which can pose health and safety risks.

How to Avoid It:

Wear protective gear, including gloves, masks, and goggles.

Ensure proper ventilation in the workspace.

Follow all safety guidelines provided by the powder manufacturer.

9. Rushing the Process

Mistake: Trying to speed up surface preparation, application, or curing.

Why It’s a Problem: Rushing can lead to incomplete cleaning, uneven application, or improper curing, resulting in a subpar finish.

How to Avoid It:

Allocate sufficient time for each step of the process.

Follow a systematic approach to ensure thorough preparation and application.

Be patient and allow the coating to cure fully before handling.

10. Failing to Maintain Equipment

Mistake: Neglecting the maintenance of spray guns, ovens, and other equipment.

Why It’s a Problem: Poorly maintained equipment can lead to inconsistent application, contamination, or curing issues.

How to Avoid It:

Clean spray guns and nozzles regularly to prevent clogs.

Calibrate ovens and temperature controls periodically.

Replace worn or damaged parts promptly.

Conclusion

Epoxy powder coating is a powerful finishing solution, but avoiding common mistakes is crucial to achieving the best results. By focusing on proper surface preparation, correct application techniques, and adherence to safety and quality control measures, you can ensure a durable, attractive, and long-lasting finish. Whether you’re a professional or a DIY enthusiast, these tips will help you maximize the benefits of epoxy powder coating and avoid costly errors.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Latest news

Have Anything To Ask Us?