Can Ultra-Thin Epoxy Layers Insulate Miniaturized Electronics?

Miniaturized electronics, such as wearables, IoT devices, and medical implants, demand compact yet reliable insulation to ensure safety and performance. Ultra-thin epoxy powder coatings, typically 50–200 microns thick, are emerging as a solution due to their high dielectric strength and versatility. This article explores whether ultra-thin epoxy layers can effectively insulate miniaturized electronics, their benefits, challenges, and best practices for application. Aimed at engineers, designers, and electronics manufacturers, this guide provides clear, actionable insights to optimize insulation in compact devices.

What Are Ultra-Thin Epoxy Layers?

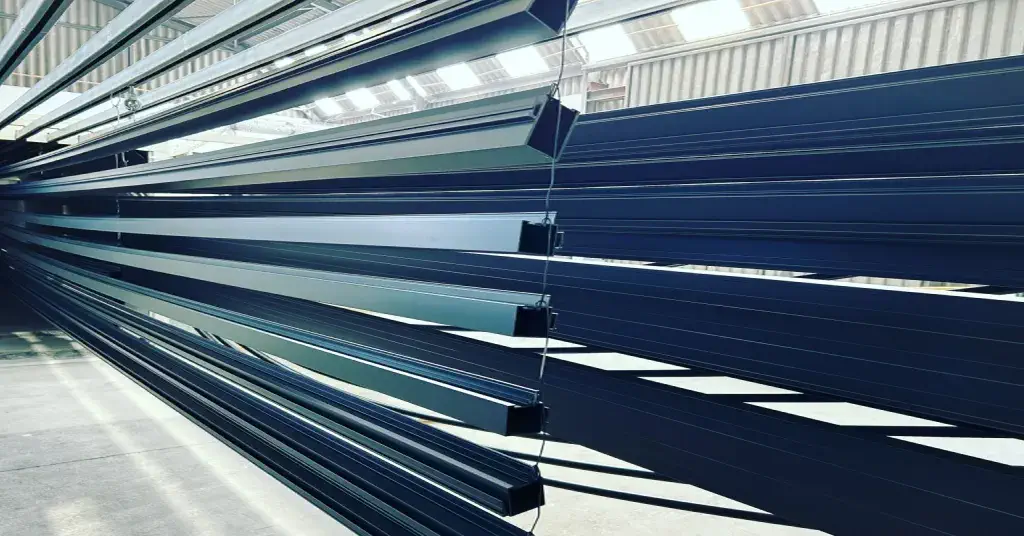

Ultra-thin epoxy layers are thermosetting powder coatings applied at thicknesses of 50–200 µm (0.05–0.2 mm) to insulate electrical components. Unlike traditional thicker coatings (500–5,000 µm), these layers are designed for space-constrained applications while maintaining dielectric strengths of 10–40 kV/mm. Applied via precision electrostatic spraying, they form a uniform, durable barrier that protects against electrical breakdown, moisture, and mechanical stress. Their key properties include:

- High Dielectric Strength: Prevents short circuits in high-density circuits.

- Compact Profile: Ideal for miniaturized components like PCBs or sensors.

- Environmental Resistance: Shields against humidity, dust, and chemicals.

- Thermal Stability: Supports operation up to 130–155°C (Class B/F insulation).

Can Ultra-Thin Epoxy Layers Insulate Miniaturized Electronics?

Dielectric Performance in Thin Layers

Ultra-thin epoxy layers can effectively insulate miniaturized electronics, provided their dielectric strength meets the application’s voltage requirements. For example:

- A 100 µm layer with a dielectric strength of 30 kV/mm provides a breakdown voltage of 3,000 volts, sufficient for low-voltage devices like wearables (3–12V).

- A 200 µm layer achieves 6,000 volts, suitable for IoT sensors or medical devices operating at 24–48V.

However, for higher voltages (>100V), thicker coatings (300–500 µm) or alternative materials like polyimide films may be needed. Manufacturers like SolEpoxy offer ultra-thin epoxy powders (e.g., DK15-0607) with dielectric strengths up to 35 kV/mm, enabling reliable insulation in compact designs.

Challenges in Ultra-Thin Insulation

While effective, ultra-thin epoxy layers face challenges in miniaturized electronics:

- Uniformity: Achieving consistent thickness on complex geometries (e.g., microchip edges) requires precise application to avoid thin spots that reduce breakdown voltage.

- Defects: Micro-voids or pinholes in ultra-thin layers can lead to dielectric failure, especially under high humidity or thermal stress.

- Adhesion: Strong bonding to substrates like FR4, copper, or ceramics is critical to prevent delamination in compact, high-density circuits.

- Thermal Limits: Most ultra-thin epoxies are rated for 130–155°C, limiting their use in high-heat applications like automotive electronics (>180°C).

Applications in Miniaturized Electronics

Ultra-thin epoxy layers are used in various compact electronic devices:

- Printed Circuit Boards (PCBs): Insulate traces and components to prevent short circuits in smartphones, wearables, and IoT devices.

- Sensors: Protect delicate sensor elements in medical implants or environmental monitors from electrical leakage and moisture.

- Microchips and Semiconductors: Provide conformal insulation for high-density integrated circuits, ensuring reliability in compact packages.

- Wearable Devices: Insulate flexible circuits in smartwatches or fitness trackers, balancing safety and flexibility.

- Medical Electronics: Safeguard pacemakers or diagnostic devices against body fluids and electrical faults.

Benefits of Ultra-Thin Epoxy Layers

- Space Efficiency: Thin layers (50–200 µm) fit space-constrained designs, enabling smaller, lighter devices.

- High Dielectric Strength: Supports low- to medium-voltage insulation (up to 6,000V) in compact electronics.

- Environmental Protection: Resists moisture, dust, and chemicals, ideal for wearables or IoT devices exposed to harsh conditions.

- Ease of Application: Electrostatic spraying ensures uniform coverage on complex geometries like microchips or sensors.

- Cost-Effective: Reduces material usage compared to thicker coatings, lowering production costs.

- Eco-Friendly: Solvent-free powders minimize VOC emissions, supporting sustainable manufacturing.

Limitations and Considerations

- Voltage Constraints: Ultra-thin layers are unsuitable for high-voltage applications (>100V), requiring thicker coatings or alternative materials.

- Application Precision: Requires advanced equipment and controlled environments to achieve uniform, defect-free coatings.

- Thermal Limitations: Limited to 130–155°C, necessitating silicone or ceramic coatings for higher temperatures.

- Mechanical Fragility: Thin layers may crack under excessive flexing or vibration, a concern for flexible electronics.

Comparison with Other Insulation Materials

| Material | Min Thickness (μm) | Dielectric Strength | Key Advantages | Key Limitations |

|---|---|---|---|---|

| Epoxy Powder Coating | 50–200 | 10–40 kV/mm | Compact, durable, cost-effective | Limited to 155°C, precision application |

| Polyimide Film | 25–125 | 100–300 kV/mm | Ultra-thin, high dielectric, flexible | Expensive, complex application |

| Silicone Coating | 100–500 | 5–20 kV/mm | Flexible, high temp (550°C) | Lower dielectric strength, thicker layers |

| Parylene Coating | 1–50 | 200–280 kV/mm | Ultra-thin, conformal, biocompatible | Costly, specialized equipment needed |

Top Epoxy Powder Manufacturers for Ultra-Thin Layers

| Manufacturer | Product Line | Dielectric Strength | Min Thickness (μm) | Key Features |

|---|---|---|---|---|

| SolEpoxy | DK15-0607 | 35 kV/mm | 50 | High dielectric, moisture-resistant |

| PPG Coatings | Corvel Thin-Film | 30–40 kV/mm | 75 | Uniform application, thermal stability |

| CAPLINQ | Hysol DK Series | 20–35 kV/mm | 100 | RoHS-compliant, high adhesion |

| ThreeBond | TB Thin Series | 15–30 kV/mm | 100 | Easy application, flexible |

Conclusion

Ultra-thin epoxy layers (50–200 µm) can effectively insulate miniaturized electronics, offering high dielectric strength, space efficiency, and environmental protection for devices like wearables, IoT sensors, and medical implants. While challenges like application precision and thermal limits exist, advanced formulations and best practices ensure reliable insulation. By selecting the right epoxy powder, optimizing application, and testing performance, manufacturers can enhance safety and performance in compact electronics.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?