Can modified epoxy powder coating solve the problem of outdoor UV aging?

Epoxy powder coatings are renowned for their excellent dielectric strength, adhesion, and durability, making them ideal for insulating electrical components like busbars, transformers, and EV battery packs. However, standard epoxy coatings often struggle with UV aging when exposed to outdoor sunlight, leading to chalking, color fading, and reduced insulation performance. Modified epoxy powder coatings, formulated with UV-resistant additives, offer a potential solution. This article explores whether these modified coatings can address outdoor UV aging, their benefits, limitations, and best practices for application. Written for engineers, manufacturers, and industry professionals, this guide provides clear, actionable insights to ensure reliable insulation in outdoor environments.

What Is UV Aging in Epoxy Powder Coatings?

UV aging occurs when ultraviolet (UV) radiation from sunlight degrades the polymer structure of epoxy coatings, causing:

- Chalking: Surface powdering due to resin breakdown, reducing gloss and insulation integrity.

- Color Fading: Discoloration from UV-induced pigment degradation, affecting aesthetics.

- Cracking or Brittleness: Loss of flexibility, leading to micro-cracks that expose substrates.

- Reduced Dielectric Strength: Degradation of insulation properties, increasing risks of electrical leakage or arcing.

Outdoor electrical components, such as solar inverters, wind turbine electronics, or outdoor switchgear, are particularly vulnerable to UV aging, especially in high-sunlight regions like deserts or tropics. Modified epoxy coatings aim to mitigate these issues by enhancing UV resistance while maintaining core insulation properties.

Can Modified Epoxy Powder Coatings Solve UV Aging?

How Modified Epoxy Coatings Work

Modified epoxy powder coatings incorporate UV-resistant additives and stabilizers to combat degradation:

- UV Absorbers: Compounds like benzotriazoles absorb UV radiation, preventing it from breaking polymer bonds.

- Hindered Amine Light Stabilizers (HALS): Neutralize free radicals formed during UV exposure, slowing degradation.

- Pigment Enhancements: UV-resistant pigments maintain color stability and reduce chalking.

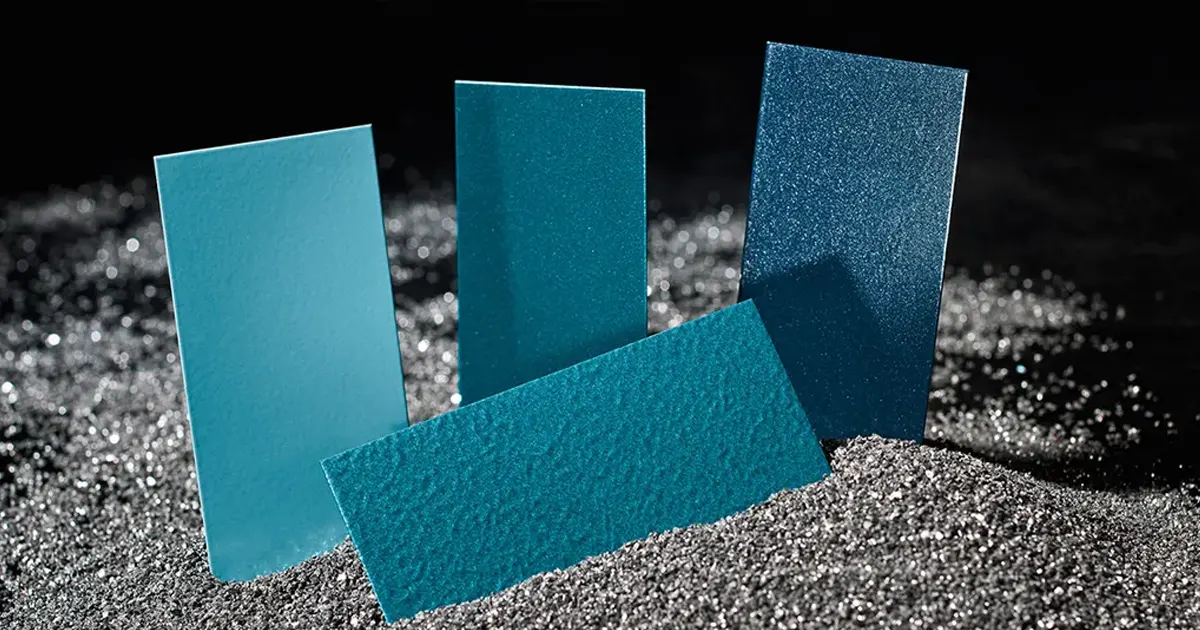

- Hybrid Formulations: Combine epoxy with UV-stable resins (e.g., polyester or acrylic) to enhance weatherability while retaining dielectric strength.

These modifications allow coatings to withstand prolonged UV exposure, maintaining insulation performance in outdoor applications. For example, SolEpoxy’s UV-modified DK15-0607 coating retains 90% of its dielectric strength (30 kV/mm) after 2,000 hours of UV testing per ASTM G154.

Effectiveness Against UV Aging

Modified epoxy coatings significantly improve UV resistance compared to standard epoxies:

- Chalking Resistance: UV stabilizers reduce surface powdering, preserving gloss and surface integrity for 3–5 years in outdoor conditions.

- Color Retention: Enhanced pigments maintain aesthetics, critical for visible components like solar panel frames.

- Dielectric Stability: Retains dielectric strength (e.g., 25–35 kV/mm) under UV stress, ensuring insulation for low- to medium-voltage systems (<38 kV).

- Mechanical Durability: Prevents cracking, maintaining adhesion and flexibility under thermal cycling and UV exposure.

Case Study: A solar inverter manufacturer in Arizona applied PPG’s UV-modified Corvel Series coating to aluminum enclosures. After 3 years of exposure (UV index 7–8), the coating showed minimal chalking and retained 95% of its original dielectric strength, compared to 60% for standard epoxy.

Limitations of Modified Epoxy Coatings

While effective, modified epoxies have limitations:

- UV Resistance Ceiling: Even with additives, epoxies are less UV-resistant than polyester or fluoropolymer coatings, limiting their lifespan to 5–10 years in extreme UV conditions.

- Dielectric Trade-Offs: Some UV-resistant formulations may reduce dielectric strength (e.g., from 30 kV/mm to 20 kV/mm) to prioritize weatherability.

- Cost: UV-modified epoxies are 20–30% more expensive than standard formulations due to specialized additives.

- Application Precision: Requires uniform thickness and proper curing to avoid defects that accelerate UV aging.

Solution: For extreme UV environments (e.g., >10 UV index), consider hybrid epoxy-polyester coatings or topcoats like polyurethane for enhanced durability.

Applications Requiring UV-Resistant Epoxy Coatings

Modified epoxy coatings are ideal for outdoor electrical components, including:

- Solar Inverters: Insulate enclosures and busbars exposed to direct sunlight, preventing UV-induced insulation failure.

- Wind Turbine Electronics: Protect control units from UV and weathering in open-air installations.

- Outdoor Switchgear: Ensure reliable insulation for power distribution systems in coastal or desert environments.

- EV Charging Stations: Insulate connectors and enclosures, balancing UV resistance with dielectric strength.

- Marine Electronics: Combine UV and moisture resistance for components exposed to sunlight and saltwater.

How to Optimize Epoxy Powder for UV Resistance

1. Select UV-Resistant Formulations

- Choose coatings with UV absorbers, HALS, and durable pigments (e.g., SolEpoxy DK15-0607 or PPG Corvel UV Series).

- Opt for hybrid epoxy-polyester formulations for enhanced UV stability without sacrificing dielectric strength.

- Request UV test data (e.g., ASTM G154 or QUV testing) to confirm performance for 2,000–5,000 hours of exposure.

2. Apply Optimal Coating Thickness

- Use 200–500 µm for low- to medium-voltage components (e.g., PCBs, enclosures) to balance UV resistance and dielectric performance.

- Apply 1,000–1,500 µm for high-voltage components like busbars, ensuring sufficient insulation while minimizing defects.

- Ensure uniformity to prevent thin spots that accelerate UV aging.

3. Enhance Surface Preparation

- Cleaning: Remove oils, oxides, or dust with chemical degreasers or solvents to ensure strong adhesion.

- Abrasive Blasting: Achieve a surface roughness of 2–4 µm Ra for mechanical bonding, reducing delamination risks under UV stress.

- Primers: Apply UV-resistant primers (e.g., epoxy-based with zinc oxide) on metals like aluminum to enhance adhesion and corrosion resistance.

4. Refine Application Techniques

- Electrostatic Spraying: Ideal for thin coatings (200–500 µm) on complex geometries like enclosures or connectors.

- Fluidized Bed Dipping: Suitable for thicker coatings (1,000–1,500 µm) on busbars, requiring preheating to 200–220°C for seamless coverage.

- Controlled Environment: Apply in cleanrooms with <50% RH to prevent moisture or dust entrapment, which can exacerbate UV aging.

5. Optimize Curing Process

- Cure at 150–200°C for 10–20 minutes to form a dense, cross-linked coating that resists UV degradation.

- Avoid over-curing (>220°C), which can embrittle coatings and increase cracking under UV exposure.

- Verify curing with differential scanning calorimetry (DSC) or dielectric strength tests (e.g., IEC 60243).

Benefits of Modified Epoxy Coatings for UV Resistance

- Extended Lifespan: Maintains insulation and aesthetics for 5–10 years in outdoor conditions.

- Reliable Insulation: Retains dielectric strength (20–35 kV/mm) under UV stress, preventing electrical failures.

- Environmental Protection: Resists moisture, chemicals, and corrosion alongside UV aging, ideal for outdoor applications.

- Cost-Effective: Balances UV resistance with affordability compared to polyester or fluoropolymer coatings.

- Versatility: Suitable for complex geometries like enclosures or busbars with bends.

- co-Friendly: Solvent-free powders reduce VOC emissions, supporting sustainable manufacturing.

Comparison with Other UV-Resistant Coatings

| Material | UV Resistance | Dielectric Strength | Key Advantages | Key Limitations |

|---|---|---|---|---|

| Modified Epoxy Coating | Good to High | 20–35 kV/mm | Cost-effective, durable, high dielectric UV | Limited to 5–10 years in extreme UV |

| Polyester Coating | Excellent | 10–20 kV/mm | Superior UV resistance, aesthetic retention | Lower dielectric strength, higher cost |

| Fluoropolymer Coating | Outstanding | 5–15 kV/mm | Extreme UV and chemical resistance | Expensive, low dielectric strength |

| Silicone Coating | High | 5–20 kV/mm | Flexible, high temp (550°C) | Weaker adhesion, costly |

| Modified epoxy coatings offer a balanced solution for outdoor electrical insulation, providing good UV resistance and high dielectric strength at a lower cost than polyester or fluoropolymer alternatives. | ||||

Top UV-Resistant Epoxy Powder Manufacturers

| Manufacturer | Product Line | Dielectric Strength | UV Resistance Features | Key Applications |

|---|---|---|---|---|

| SolEpoxy | DK15–0607 | 30 kV/mm | UV absorbers, HALS | Solar inverters, busbars |

| PPG Coatings | Corvel UV Series | 25–35 kV/mm | Hybrid epoxy-polyester | Switchgear, enclosures |

| CAPLINQ | Hysol DK Series | 20–35 kV/mm | UV-resistant pigments | Wind turbines, PCBs |

| ThreeBond | TB UV Series | 15–30 kV/mm | Flexible, weather-resistant | Marine electronics |

FAQ: Modified Epoxy Coatings for UV Aging

Typically 5–10 years, depending on UV intensity and coating formulation.

Yes, high-quality formulations retain 90–95% of dielectric strength after 2,000 hours of UV testing.

They perform well up to UV index 8–10; for higher intensity, consider polyester or fluoropolymer topcoats.

Use QUV tests (ASTM G154) and measure chalking, color retention, and dielectric strength post-exposure.

Conclusion

Modified epoxy powder coatings, enhanced with UV absorbers, HALS, and hybrid resins, effectively address outdoor UV aging by reducing chalking, color fading, and dielectric degradation. While not as UV-resistant as polyester or fluoropolymer coatings, they offer a cost-effective balance of insulation performance and weatherability for applications like solar inverters, switchgear, and EV charging stations. By selecting UV-resistant formulations, optimizing application, and testing performance, manufacturers can ensure reliable insulation in outdoor environments.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?