Can Epoxy Powder Coatings Boost Industrial Control Cable Safety?

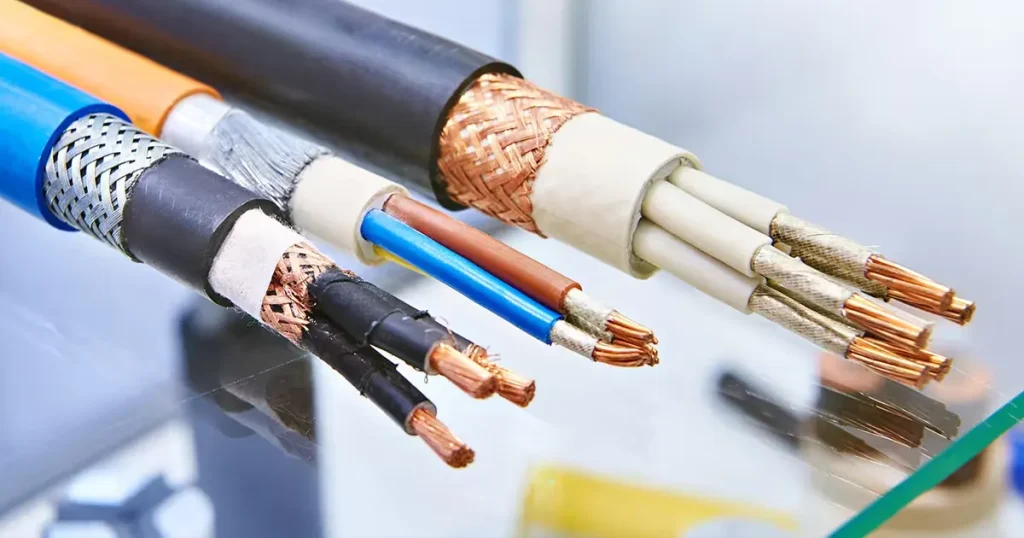

Industrial control cables are critical for transmitting signals and power in automation systems, robotics, and manufacturing equipment. These cables face harsh conditions like high voltages, mechanical stress, and environmental exposure, making robust insulation essential for safety and reliability. Epoxy powder coatings, known for their high dielectric strength and durability, are increasingly used to insulate control cables. This article explores how epoxy powder coatings enhance the safety of industrial control cables, their benefits, limitations, and best practices for application. Written for engineers, manufacturers, and industry professionals, this guide offers clear, practical insights to improve cable safety and performance.

Why Safety Is Critical for Industrial Control Cables

Industrial control cables operate in demanding environments, often handling voltages from 24V to 1,000V and facing risks like:

- Electrical Faults: Short circuits or arcing can disrupt automation systems or cause fires.

- Environmental Damage: Exposure to moisture, chemicals, or abrasion compromises insulation integrity.

- Mechanical Stress: Vibrations, bending, or impacts in industrial settings can degrade unprotected cables.

- Human Safety Risks: Insulation failures increase the risk of electrical shocks or equipment malfunctions.

Epoxy powder coatings provide a protective, insulating layer that mitigates these risks, ensuring safe and reliable operation in factories, robotics, and heavy machinery.

How Epoxy Powder Coatings Enhance Cable Safety

1. High Dielectric Strength

Epoxy powder coatings offer dielectric strengths of 10–50 kV/mm, preventing electrical breakdown in control cables:

- Low-Voltage Cables (24–300V): Thin coatings (100–300 µm) provide breakdown voltages of 1,000–9,000V, sufficient for most control systems.

- Medium-Voltage Cables (300–1,000V): Thicker coatings (500–1,000 µm) achieve breakdown voltages up to 30,000V, ideal for high-power automation equipment.

This high dielectric strength prevents short circuits and arcing, reducing fire risks and ensuring system reliability.

Example: SolEpoxy’s DK15-0607 coating, with a dielectric strength of 30 kV/mm, provides a breakdown voltage of 9 kV at 300 µm, safeguarding 480V control cables in robotic systems.

2. Environmental Protection

Control cables in industrial settings face moisture, chemicals, and dust, which can degrade insulation. Epoxy coatings offer:

- Moisture Resistance: Hydrophobic formulations block water ingress, preventing corrosion or electrical leakage in humid environments (e.g., >85% RH).

- Chemical Resistance: Protects against oils, solvents, or cleaning agents common in manufacturing plants.

- Dust and Debris Resistance: Smooth, non-porous coatings prevent dust accumulation, maintaining insulation performance.

3. Mechanical Durability

Industrial control cables endure bending, vibrations, and abrasion. Epoxy coatings provide:

Abrasion Resistance: Withstands wear from cable flexing or contact with machinery, preventing insulation breaches.

- Impact Resistance: Protects cables from physical damage during installation or operation.

- Flexibility: Certain epoxy formulations maintain adhesion during repeated bending, ideal for dynamic applications like robotics.

Example: CAPLINQ’s Hysol DK Series coating on flexible control cables maintained integrity after 10,000 bending cycles in an automotive assembly line.

4. Thermal Stability

Control cables often operate in high-temperature environments (e.g., near motors or in hot climates). Epoxy coatings with Class B (130°C) or Class F (155°C) ratings:

- Maintain dielectric strength under heat, preventing insulation breakdown.

- Resist thermal cycling, reducing cracking or delamination in fluctuating temperatures.

5. Fire Safety

Epoxy coatings meeting UL 94 V-0 standards provide flame resistance, reducing fire risks if arcing occurs. This is critical in industrial settings with flammable materials, enhancing overall safety.

Applications of Epoxy Coatings in Industrial Control Cables

Epoxy powder coatings are applied to various control cable components to boost safety:

- Cable Insulation: Coats individual conductors or bundled cables to prevent short circuits.

- Connectors and Terminals: Insulates connection points to reduce arcing risks.

- Cable Trays and Conduits: Protects metal trays or conduits from corrosion and electrical faults.

- Robotic Systems: Insulates cables in dynamic applications, resisting bending and vibration.

- PLC Systems: Ensures reliable signal transmission in programmable logic controllers (PLCs) under harsh conditions.

Benefits of Epoxy Powder Coatings for Cable Safety

- Enhanced Electrical Safety: High dielectric strength prevents arcing and short circuits, protecting workers and equipment.

- Environmental Resistance: Shields cables from moisture, chemicals, and dust, extending lifespan in harsh industrial settings.

- Mechanical Durability: Resists abrasion, bending, and impacts, ideal for dynamic applications.

Thermal Stability: Maintains insulation at temperatures up to 155°C, ensuring reliability near heat sources.

- Fire Resistance: UL 94 V-0 coatings reduce fire risks, enhancing workplace safety.

- Eco-Friendly: Solvent-free powders minimize VOC emissions, supporting sustainable manufacturing.

How to Optimize Epoxy Powder Coatings for Control Cable Safety

1. Select High-Performance Formulations

2. Apply Optimal Coating Thickness

- Use 100–300 µm for low-voltage cables (24–300V) to balance insulation and flexibility.

- Apply 500–1,000 µm for medium-voltage cables (300–1,000V) to ensure sufficient breakdown voltage.

- Ensure uniform thickness to avoid weak spots, using thickness gauges for verification.

3. Enhance Surface Preparation

- Cleaning: Remove oils, dust, or oxides with chemical degreasers or solvents.

Abrasive Blasting: Achieve a surface roughness of 2–4 µm Ra on metal connectors or conduits for better adhesion.

- Primers: Use epoxy-based primers to enhance bonding on copper or aluminum surfaces.

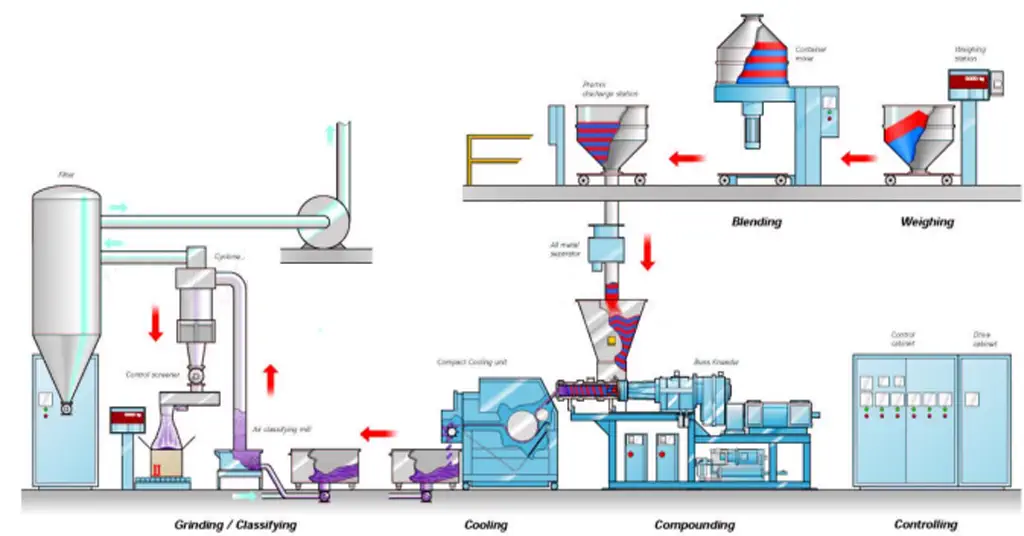

4. Refine Application Techniques

- Electrostatic Spraying: Ideal for thin coatings (100–500 µm) on cables or connectors, ensuring uniform coverage.

- Fluidized Bed Dipping: Suitable for thicker coatings (500–1,000 µm) on rigid components like conduits, requiring preheating to 200–220°C.

- Controlled Environment: Apply in cleanrooms with <50% RH to prevent moisture or dust entrapment.

5. Optimize Curing Process

- Cure at 150–180°C for 10–20 minutes to form a dense, flexible coating.

- Avoid over-curing (>200°C), which can embrittle coatings and reduce flexibility.

- Verify curing with dielectric strength tests (e.g., IEC 60243) to confirm insulation performance.

6. Test and Validate Safety

- Conduct dielectric strength tests using testers like Megger MIT410/2 to ensure breakdown voltage meets requirements.

- Perform accelerated aging tests (e.g., 85°C/85% RH per IEC 60068) to simulate harsh industrial conditions.

- Inspect for adhesion and flexibility using ASTM D3359 cross-hatch tests and bending cycle tests.

Comparison with Other Insulation Materials

| Material | Dielectric Strength | Flexibility | Key Advantages | Key Limitations |

|---|---|---|---|---|

| Epoxy Powder Coating | 10–50 kV/mm | Moderate | High dielectric, durable, eco-friendly | Limited flexibility, application precision |

| PVC Insulation | 5–15 kV/mm | High | Flexible, low-cost, easy to apply | Lower durability, poor thermal stability |

| Silicone Coating | 5–20 kV/mm | High | Flexible, high temp (550°C) | Lower dielectric strength, higher cost |

| Polyurethane Coating | 5–15 kV/mm | High | Flexible, good adhesion | Limited thermal and chemical resistance |

| Epoxy coatings offer superior dielectric strength and durability compared to PVC or polyurethane, making them ideal for industrial control cables, though flexibility may require specialized formulations. | ||||

Top Epoxy Powder Manufacturers for Cable Insulation

| Manufacturer | Product Line | Dielectric Strength | Key Features | Key Applications |

|---|---|---|---|---|

| SolEpoxy | DK15–0607 | 30 kV/mm | Flexible, moisture-resistant | Robotics, PLC systems |

| PPG Coatings | Corvel Series | 25–35 kV/mm | Chemical-resistant, UL 94 V-0 | Industrial automation |

| CAPLINQ | Hysol DK Series | 20–35 kV/mm | High adhesion, RoHS-compliant | Control cables, connectors |

| ThreeBond | TB Series | 15–30 kV/mm | Vibration-resistant, easy application | Automotive controls |

FAQ: Epoxy Coatings for Control Cable Safety

Yes, with flexible formulations, but may crack in extreme bending without proper additives.

Yes, with moisture- and UV-resistant formulations for outdoor industrial environments.

Clean substrates thoroughly, use primers, and apply in controlled environments (<50% RH).

Ideal for low- to medium-voltage cables (24–1,000V), depending on coating thickness.

Conclusion

Epoxy powder coatings significantly boost industrial control cable safety by providing high dielectric strength, environmental protection, mechanical durability, and fire resistance. By selecting flexible, high-performance formulations, optimizing thickness, and ensuring proper surface preparation and curing, manufacturers can prevent electrical faults, enhance worker safety, and extend cable lifespan. While limitations like flexibility and cost exist, careful application and testing mitigate these challenges.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?