Application of pure polyester powder coating in automotive parts field

Pure polyester powder coating has been widely used in the field of automotive parts. We can often see pure polyester powder coatings on car chassis, wheels, engine parts, car exhaust systems and car exteriors. But do you know why pure polyester powder coatings can be widely used in the field of automotive parts? Do you know what matters need to be paid attention to when applying pure polyester powder coating to automobile parts? In this article, we will reveal this secret for you comprehensively and systematically

1. What are the automotive parts that use pure polyester powder coatings?

a. Vehicle Components

Chassis and Frames:

Pure polyester powder coatings are applied to chassis and frames to provide corrosion resistance, ensuring the structural integrity of the vehicle. The coatings also offer excellent impact resistance, protecting these critical components from road debris and environmental factors.

Coating wheels and rims with pure polyester powder coatings not only enhances their visual appeal but also improves their resistance to chipping, abrasion, and harsh weather conditions. These coatings come in a variety of colors and finishes, allowing for customization to match the vehicle’s design.

b. Engine Parts

Engine components, such as valve covers and intake manifolds, benefit from pure polyester powder coatings for their thermal stability and resistance to chemical exposure. The coatings can withstand high temperatures without discoloration or degradation, making them ideal for under-the-hood applications.

c. Exhaust Systems

Pure polyester powder coatings are commonly used to protect exhaust systems from extreme heat and corrosive gases. They prevent rust and maintain the appearance of the exhaust, contributing to a longer service life and improved overall vehicle performance.

d. Exterior Trim and Accessories

Exterior trim and accessories like door handles, grilles, and mirror housings benefit from these coatings, as they provide a sleek and durable finish. Pure polyester powder coatings ensure that exterior elements maintain their appearance even after exposure to UV rays and harsh weather conditions.

2. Benefits of Pure Polyester in the Automotive Industry

a. Durability and Corrosion Resistance

Pure polyester coatings are renowned for their exceptional durability and resistance to corrosion. These coatings form a robust, protective layer on various automotive components, ensuring their longevity and structural integrity.

Chassis and Frame Protection: Pure polyester coatings shield chassis and frames from corrosion, particularly in harsh environmental conditions and on salt-covered roads. This safeguarding significantly extends the lifespan of these crucial components.

Wheel and Rim Durability: When applied to wheels and rims, these coatings enhance their resistance to corrosion and abrasion. They help maintain the wheels’ structural integrity and appearance, even under challenging conditions.

b. UV Resistance and Color Retention

Pure polyester coatings are known for their remarkable UV resistance and ability to retain vibrant colors. These qualities are essential for automotive parts exposed to sunlight and the elements.

Exterior Trim Preservation: Coating exterior trim and accessories with pure polyester keeps them looking as good as new for extended periods. The coatings protect against UV rays, preventing fading and maintaining the parts’ original color.

Vibrant Wheels and Rims: When used on wheels and rims, these coatings ensure that the vibrant colors and finishes stay intact, enhancing the overall aesthetic appeal of the vehicle.

c. Chemical Resistance

The automotive industry often involves exposure to various chemicals, making chemical resistance a critical attribute of coatings.

Engine Part Protection: Pure polyester coatings are used on engine components such as valve covers and intake manifolds due to their resistance to oil, fuel, and other chemicals. This ensures that these parts remain functional and maintain their appearance, even in demanding environments.

Exhaust System Durability: Coating exhaust systems with pure polyester coatings protects them from corrosive gases and chemicals, preventing rust and ensuring optimal performance.

d. Enhanced Aesthetics

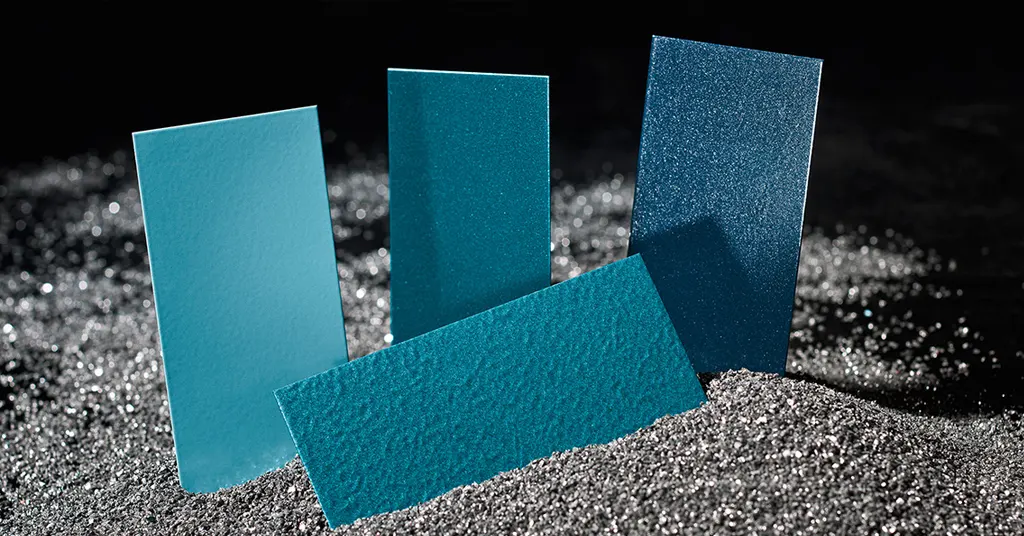

Versatile Aesthetic Choices: These coatings come in a wide range of colors and finishes, allowing for customization to match the vehicle’s design and style.

Sleek Exterior Appearance: Whether it’s door handles, grilles, or mirror housings, pure polyester coatings enhance the exterior’s sleek appearance, contributing to a visually appealing vehicle

3. Surface Preparation for Automotive Parts

Surface treatment of automotive parts plays a vital role in ensuring coating adhesion and quality. How to achieve a quality surface finish through cleaning and contaminant removal, surface roughness and inspection, and achieving proper adhesion are key in pure polyester powder coatings for automotive component applications.

a. Cleaning and Contaminant Removal

Before coating automotive parts, the surface must be thoroughly cleaned to ensure the coating will adhere properly and provide long-lasting protection. The cleaning process should include the following steps:

Remove grease and grime: Use specialized cleaners and solvents to remove grease, grime and other organic matter from surfaces. This can be achieved by using detergents, degreasers and solvents.

Dissolve and remove oxide layers: Oxide layers are a common problem when it comes to metal surfaces. Using an acidic cleaner or pickling process can effectively dissolve and remove the oxide layer to restore the purity of the metal surface.

Acid and alkaline cleaning: For certain metal materials, acid and alkali cleaning can further clean the surface and remove residual contaminants. These treatments can be selected based on specific material and application requirements.

b. Surface roughness and inspection

Surface roughness is critical for coating adhesion. The following are some common surface roughness treatment and detection methods:

Grinding wheel polishing: For metal surfaces, polishing with a grinding wheel or other abrasive tool can improve the surface roughness. This helps provide better adhesion and coating uniformity.

Sand blasting and shot blasting: Sand blasting and shot blasting are common surface treatment methods for some larger automotive parts. By spraying particulate materials at high speed, surface contaminants, oxide layers and bad coatings can be removed while providing a certain surface roughness.

Surface Inspection: During the surface treatment process, it is necessary to inspect the surface to ensure that the required roughness is achieved. Common surface inspection methods include the use of tools such as optical microscopy, scanning electron microscopy, and surface profilometry.

c. Achieve proper adhesion

To achieve proper coating adhesion, here are some key factors to consider:

Applying Primer and Powder Coating: Primers provide good adhesion and uniformity of the coating. The choice of powder coating should match the primer to ensure affinity and interaction between the two.

Paint Curing and Baking: Proper paint curing and baking process is critical to achieving good adhesion. Be sure to cure and bake at the correct temperature and time for optimal adhesion, according to the paint manufacturer’s instructions.

Surface treatments and adhesives: Using appropriate surface treatments and adhesives can enhance coating adhesion. These chemicals provide additional adhesion, ensuring a strong bond between the coating and the substrate.

Pure polyester powder coatings are increasingly used in the field of automotive parts due to their excellent durability and corrosion resistance, UV resistance, chemical resistance and excellent color protection. With technological innovation in the field of powder coatings, more and more different types of powder coatings will enter the field of automotive parts in the future.

Have Anything To Ask Us?