Application of powder coating in automotive field

Powder coatings are widely used in the automotive field. Powder coatings can provide cars with brilliant exterior colors, protect the vehicle surface from scratches, greatly improve the durability of related auto parts, and play an important role in environmental protection. When used for body painting, powder coatings can provide long-lasting appearance protection, effectively resist ultraviolet radiation, and are also very effective in protecting against chemical corrosion and scratches. In addition, powder coatings are also used in automobile wheels and aluminum alloy parts, exhaust systems, automobile chassis and suspension components, engines and transmission systems.

Powder coatings for automobiles

automotive body powder painting

Wheel hub coating

Automotive exhaust system

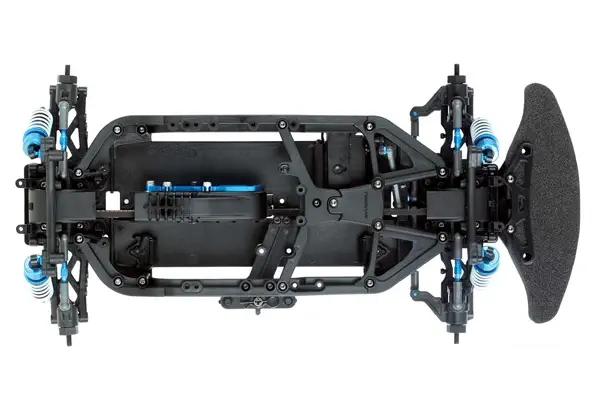

automotive chassis painting

automotive dashboard

Car engine spraying

car brake parts

Car luggage rack

Types of powder coating for automotive field

If you need a special type of powder coating or would like to customize a powder coating in a different RAL color, please contact us right now!

Alternative Automotive Powder Coatings

FAQs About Powder Coating in automotive Field

Powder coating is preferred due to its superior durability, resistance to chipping, fading, and corrosion, and its environmentally friendly process (no solvents or volatile organic compounds). It also provides a more uniform, attractive finish and can be more cost-effective in the long run.

While powder coating can be applied to many parts of a vehicle, it’s not suitable for everything. Parts that can withstand the curing temperatures (usually around 400°F) are ideal. It’s commonly used on wheels, frames, bumpers, and some engine parts but not suitable for most interior components or parts that are sensitive to heat.

Powder coating is highly durable and resistant to scratches, chipping, and fading. It can last for several years, even under challenging conditions, making it ideal for automotive applications.

Yes, powder coating is more environmentally friendly than traditional liquid paint as it contains no solvents and releases negligible amounts of volatile organic compounds (VOCs). Any overspray can be recycled, reducing waste.

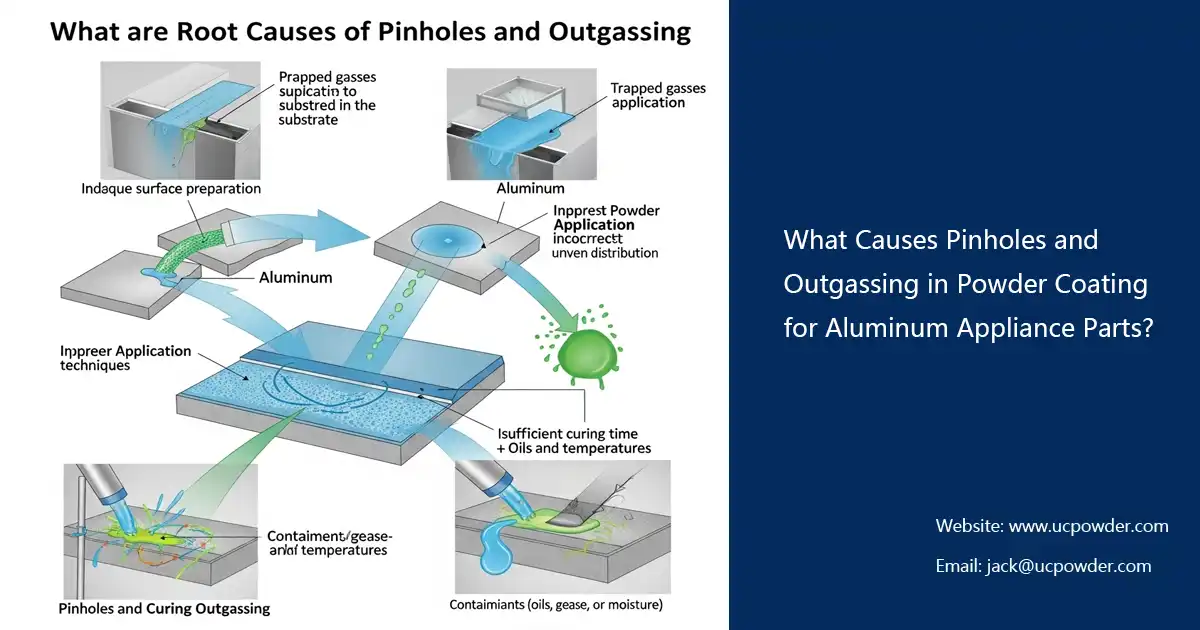

The process involves surface preparation (cleaning and sandblasting), applying the powder (using an electrostatic spray gun), and then curing the part in an oven, where the powder melts and forms a uniform, solid coat.

Yes, powder coating comes in a wide range of colors, textures, and finishes, including glossy, matte, and metallic. This allows for significant customization to match or complement the vehicle’s overall aesthetics.

Maintenance is relatively easy. Regular cleaning with mild soap and water is usually sufficient. Avoid using harsh chemicals or abrasive cleaners as they might damage the coating.

While powder coating is very durable, if it does get damaged, repairs can be more challenging than traditional paint. It often requires the entire part to be recoated to ensure a uniform finish.

Have Anything To Ask Us?