Analysis Of Formula For Heat-resistant Epoxy Powder Coating

Table of Contents

Heat-resistant powder coating refers to a protective powder coating that can withstand high temperatures above 200 ℃ for a long time, without discoloration or damage to the coating film, and still maintain appropriate physical and mechanical properties. The heat resistance of organic silicon powder coatings is relatively high, but their price is high, and their initial appearance and mechanical properties are not very good. The curing temperature is high, and it is quite difficult to obtain a coating film that can withstand high temperatures above 400 ° C for a long time.

Although the heat resistance of epoxy resin itself is inferior to that of silicone resin, its performance is relatively comprehensive; By modifying and adding appropriate curing agents and fillers, good heat resistance can also be achieved. Therefore, heat-resistant epoxy powder coatings have been widely used.

1. Performance requirements for heat-resistant epoxy powder coatings

a. Heat resistance

Heat resistance is the most important performance indicator of heat-resistant epoxy powder coatings. Because heat-resistant epoxy powder coatings may not be used for a long time at high temperatures, the heat resistance of epoxy powder coatings can be divided into two types: long-term and short-term. According to the performance requirements of the target audience and other aspects, selecting appropriate modified epoxy resins, curing agents, and fillers is necessary to achieve the goal of affordability and good quality.

b. Mechanical properties

The mechanical properties of heat-resistant epoxy powder coatings include the initial and later mechanical properties. Due to certain limitations in the selection of curing agents and fillers, their mechanical properties may be slightly lower than the requirements of general powder coatings; But it is important not to reduce the mechanical performance too much in the later stage.

c. Corrosion resistance (including chemical resistance)

Due to the good anti-corrosion performance of epoxy resin, heat-resistant epoxy powder coatings can fully meet this requirement.

d. appearance

The appearance properties of heat-resistant epoxy powder coatings include flatness, gloss, color, and other aspects. The flatness can vary depending on the object of use. Mild orange peel should generally be allowed. Gloss mostly requires a flat and matte finish. It is difficult to maintain color consistency with light colors and requires the addition of appropriate antioxidants and hindered amines to solve the problem.

2. Composition of raw materials for heat-resistant epoxy powder coatings

a. Selection of epoxy resin types

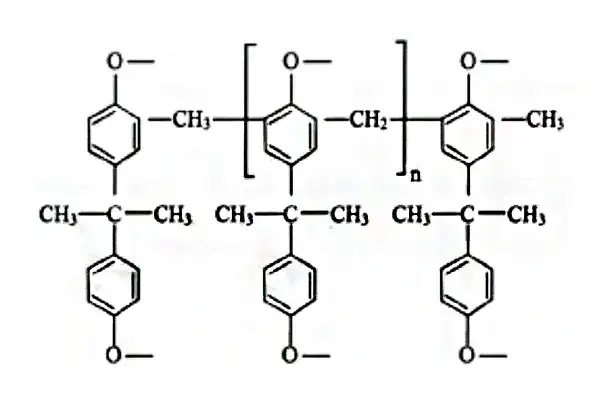

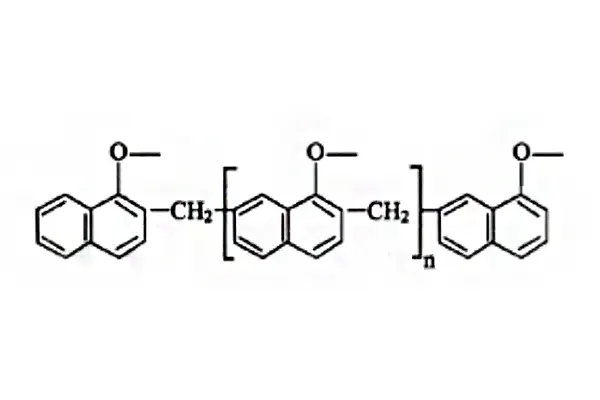

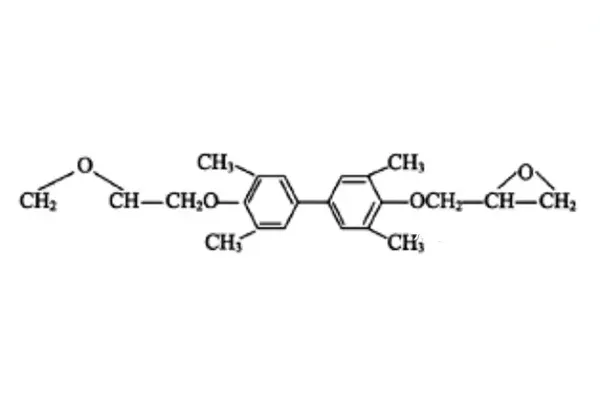

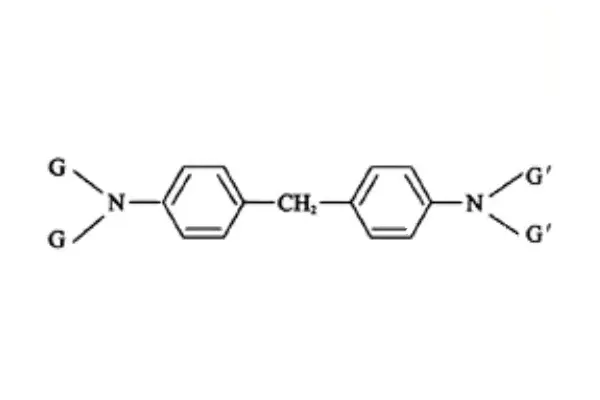

Generally, bisphenol A epoxy resin is used. Other epoxy resins with good heat resistance include naphthalene ring phenolic aldehyde epoxy resin, diphenyl epoxy resin, 4-4 ‘- diaminodiphenylmethane tetraglycidyl amine, etc.

b. Modification of epoxy resin

Organic silicone resin modification

Polysiloxane modified epoxy resin can not only reduce the internal stress of epoxy resin, but also increase its flexibility and high-temperature resistance. By reacting the active end groups of polysiloxane (Si-OH, – NH2, alkoxy, etc.) with the epoxy and hydroxyl groups of epoxy resin, block polymers are formed.

For example, adding cyclohexanone solution of epoxy resin and xylene solution of active silicone to a three necked flask, adding catalyst aluminum triacetylacetone, heating up to reflux temperature, and after the reaction is completed, the solvent is evaporated under reduced pressure to obtain silicone modified epoxy resin. Mechanical mixing of epoxy resin and methylphenyl silicone resin can also achieve the purpose of modification

Methyl phenyl silicone resin powder (100-250 mesh) 100 parts

45 parts of epoxy resin (100-250 mesh)

Lead glass powder (melting point 450 ℃, 200-400 mesh) 150 parts

Fe2O3 (1 μ m) 3 copies

The obtained powder coating can withstand high temperatures of 500-700 ℃ without peeling off

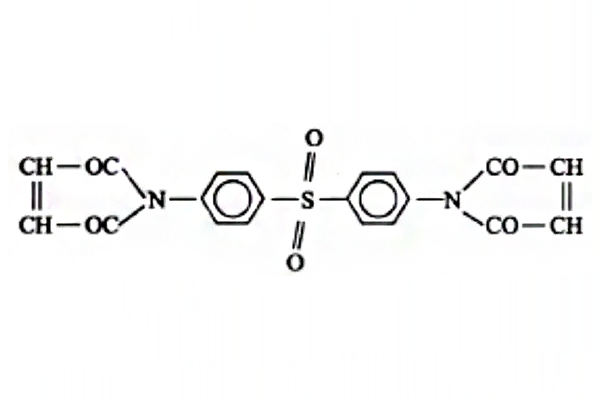

Modification of malamide compounds

The formula of apple amide modified epoxy powder coating is as follows:

30 parts of apple amide compounds

70 parts of epoxy resin

50 parts linear cresol formaldehyde resin

Two parts of dimethyl imidazole

Initial cutting force/(kg · cm-2) 150

Heat resistance rate */% 80

c. Nano filler modified epoxy resin

The nano SiO2 epoxy resin composite material prepared by in-situ dispersion polymerization using silicon coupling agent has a good reinforcing and toughening effect on the epoxy resin; And improved the heat resistance of epoxy resin.

Preparation method of nano SiO2 modified epoxy resin: Dry nano SiO2 is added to an acetone solution with coupling agent in a stirring state, and then treated with ultrasound for 30 minutes. The solution and epoxy resin are stirred evenly, and the solvent is removed. The reaction is carried out at 130 ℃ for 1 hour, and then cooled. Nano montmorillonite modified epoxy resin can also improve the heat resistance and flame retardancy of epoxy resin.

d. Selection of curing agent

The type of curing agent also has a significant impact on the heat resistance of epoxy resin. Generally speaking, anhydride curing agents have good heat resistance. There are several commonly used curing agents, such as: pyromellitic dianhydride(PMDA), Benzone tetraacetic anhydride(BTDA), Imidazole ester of phthalic anhydride.

e. Selection of pigments

Generally, inorganic pigments have good heat resistance and can be used in most cases. Black pigments can use chromium copper pigments (produced by SheperdColor). Aluminum powder also has good heat resistance, but it is prone to discoloration at high temperatures; Can be pre coated with fluorocarbon resin.

f. Selection of fillers

Generally, inorganic fillers have good heat resistance, among which silica fume powder (calcium silicate) and mica powder are more suitable. Both can be used alone or in combination in a certain proportion. Potassium hexatitanate whiskers can also be used, which not only has good heat resistance, but also improves the hardness, wear resistance, chemical stability, and weather resistance of the coating, with a dosage of 5% to 30%.

Conclusion

There are many varieties of high-temperature resistant polymers, but there are still certain difficulties and problems in preparing powder coatings that can meet the requirements in all aspects of performance. By modifying epoxy resin and selecting appropriate curing agents and fillers, powder coatings with different high temperature requirements (200-600 ℃) can be produced.

Heat resistant epoxy powder coating can be widely used in household appliances, such as ovens, heaters, high-power lighting, as well as high-temperature parts of mechanical equipment, such as smoke exhaust pipes, high-temperature furnaces, petrochemical devices, aircraft, missiles, aerospace equipment, etc. for coating protection. Heat resistant epoxy powder coating can also be used for coating electrical insulation materials. Brominated epoxy resin or appropriate flame retardants can also be used as flame retardant powder coatings.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Latest news

Have Anything To Ask Us?