Powder Coating Gun Selection: Factors to Consider

Choosing the right powder coating gun is crucial, not only to improve powder coating efficiency but also to reduce your spraying costs. So, how to choose the best powder coating gun? What factors should you consider when choosing a powder coating gun? Faced with these problems, we provide complete solutions in this article.

1. The size of the workpiece to be sprayed

For workpieces with a length, width and height exceeding 1 meter, it is recommended that you use an industrial powder spray gun. Industrial powder spray guns have the characteristics of large spraying range and high spraying efficiency, and can meet the spraying needs of large workpieces.

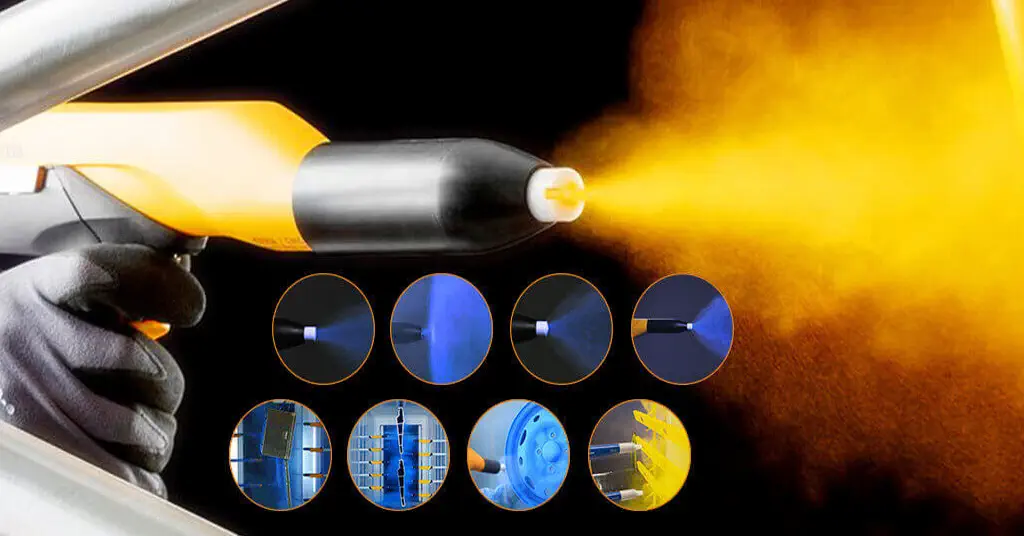

For small or special-shaped workpieces to be sprayed, it is recommended that you use a handheld powder spray gun. The handheld powder spray gun is compact, flexible and easy to operate. Especially when it comes to parts with special-shaped structures that are difficult to spray, handheld powder spray guns perform better than industrial powder spray guns.

2. Types of powder coating

Different types of powder coatings have greatly different performance requirements for powder spray guns. Taking epoxy resin powder as an example, it usually requires a higher charge to ensure that the powder is evenly distributed on the surface of the workpiece and adheres well. UV-sensitive powder coatings need to be cured under ultraviolet light, and the powder spray gun needs to work in coordination with the ultraviolet light source. This requires special powder coating gun configurations and configurations to ensure the coating can achieve the desired hardening effect when exposed to UV light.

3. Different powder delivery methods

Powder coatings generally use pneumatic transportation to transport the powder coatings into the powder spray gun. The diameter and length of the conveyor system will affect the speed and uniformity of powder delivery. Longer or thinner delivery tubes require powder coating guns with higher gas flow and charge conditions capabilities to ensure that the powder can effectively reach the nozzle.

Some powders are very sensitive to temperature and humidity. The humidity and stability in the conveying system simply rely on the environmental control of the construction workshop is not enough to achieve the corresponding parameter indicators. At this time, we need a special powder spray gun to prevent the powder coating from agglomerating or absorbing moisture during the conveying process.

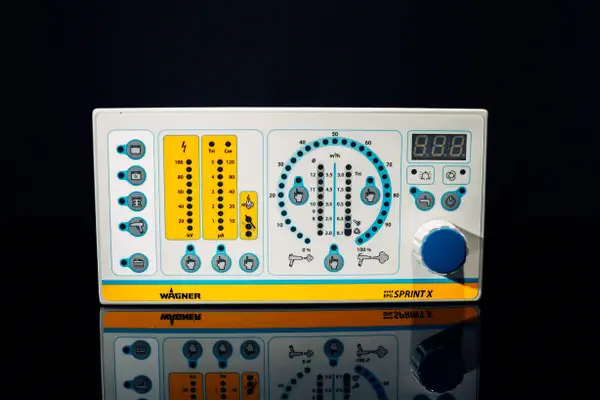

4. Electric charge control system

Different types of powders may require different strengths of charge for optimal adhesion. Epoxy resin powder requires a strong charge to be firmly adsorbed on the surface of the workpiece. In addition, the charge required during the spraying process of powder coatings is also related to the properties of the powder. Powder coatings with high solids, high fillers, and high particle sizes require more charges, while powder coatings with low solids, low fillers, and finer particle sizes do not require more charges.

5. Durability and ease of maintenance

Powder spray guns need to have good durability to avoid frequent damage during short periods of use. When experiencing strong air pressure output spray, the delivery pipe and nozzle of the powder spray gun need to effectively resist the impact of high-speed polyester powder. The charge control system also needs to ensure that each polyester powder particle is negatively charged.

In the long-term use of powder spray guns, it is inevitable that various problems will lead to work failures. Quick replacement of vulnerable components is an issue that should be considered when choosing a powder spray gun. After all, lengthy maintenance can have a huge impact on your powder coating job.

6. Brand and after-sales service

The brand does not necessarily mean the high quality of the powder spray gun, but relatively speaking, the overall performance of the brand spray gun will be better. Graco, Nordson, SATA, ANEST-IWATA, Devilbiss and other brands are well-known in the field of powder spraying, and their product performance has also been highly praised by users.

After-sales service for your powder coating gun is also a factor worth considering. Perfect after-sales service can provide you with comprehensive technical service support when you face powder spray gun failure. Getting solutions from the manufacturer’s technical team in a short time can allow you to avoid more business losses.

7. Procurement budget and costs

The purchasing budget is directly related to the selection of powder spray gun. If you don’t have sufficient purchasing budget, you can only choose powder coating guns with relatively high cost performance. For an expensive and multi-functional powder coating gun, you may not be able to purchase it due to your limited purchasing budget.

But that doesn’t mean that a more expensive powder coating gun is necessarily suitable for your powder coating business. You should choose the most appropriate powder coating gun based on your actual powder coating job needs.

There are many factors to consider when choosing the right powder coating gun. The size of the workpiece to be sprayed, the type of powder coating, different powder delivery methods, charge control systems, durability and ease of repair, brand and after-sales service, as well as purchasing budget and spray gun cost are all factors when you choose a powder spray gun factors that must be considered. Only by comprehensively analyzing and comparing the above influencing factors can you choose the most suitable powder spray gun according to your actual situation.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?