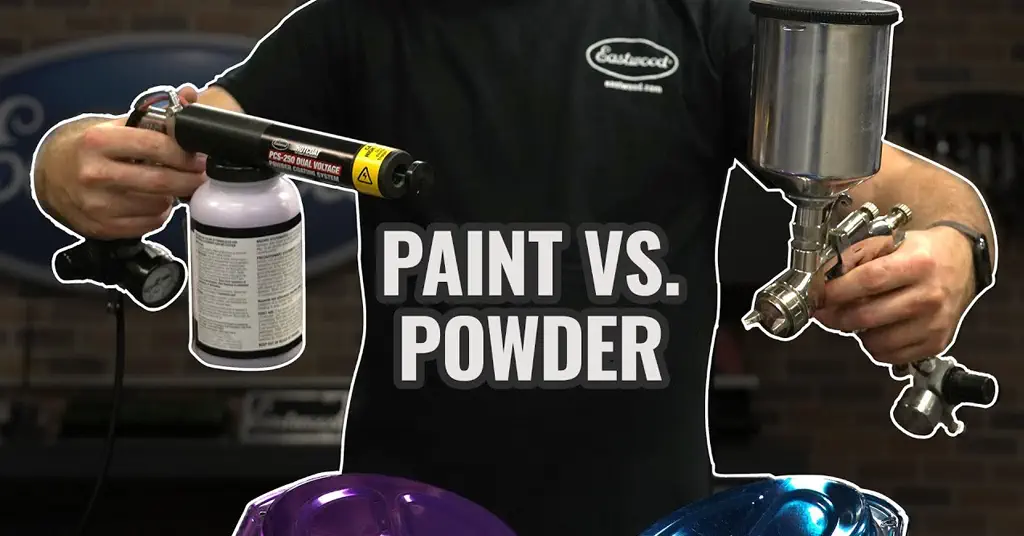

Powder Coating Gun vs. Spray Paint Gun: Which Is Better for You

Powder coating guns and spray paint guns are both commonly used tools in the coating process, but they have certain differences in principles, performance, application situations, etc. For different painting needs, choosing the right painting tools is crucial. In this article, we’ll provide a detailed comparison between powder coating guns and spray paint guns to help you understand the differences between them so you can choose the one that best suits your painting needs.

1. the advantages of powder coating guns

a. Environmental benefits

Powder coating guns excel when it comes to the environment. Because it contains no volatile organic solvents, powder coatings do not release harmful gases, helping to reduce air and water pollution. In addition, the powder coating process produces less waste and complies with modern environmental standards.

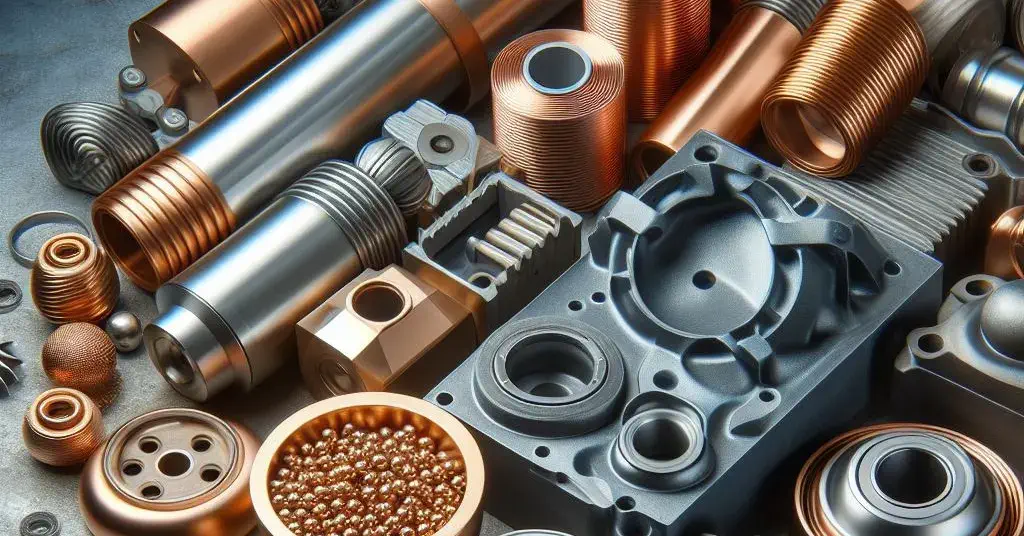

b. Quality and Durability

Powder coating guns provide superior coating quality and durability. In high-temperature environments, powder coatings melt and fuse into a solid surface, giving the coating excellent resistance to corrosion, abrasion and durability.

c. Efficiency and cost effectiveness

Powder coating guns offer significant advantages in terms of efficiency and cost-effectiveness. Due to the controllability and recyclability of the powder, unattached powder can be recycled and reused, reducing waste. The powder coating process does not require solvents, reducing coating costs.

2. the disadvantages of powder coating guns

a. Initial cost of equipment

Although powder coating guns can be cost-effective in the long run, the initial cost of the equipment is relatively high. Purchasing powder coating equipment requires a large investment, which may pose a certain burden to small businesses or start-ups. However, as the market develops and technology advances, the cost of equipment is gradually declining and may become more competitive in the future.

b. Limited color choices

Compared to some liquid coatings, powder coating is somewhat limited in color choices. Although a wide range of color options are available on the market, the formulation process of powder coating is relatively complex and may not meet certain color needs. This may be seen as a challenge in some industries that are very color-sensitive, such as art and design.

c. Complexity of the operation process

The operation process of powder coating is relatively complex and requires skilled skills and experience. Correct settings and adjustments are key to ensuring coating quality, and this requires a certain level of expertise on the part of the operator. For beginners or untrained operators, it may take some time to adapt and master operating techniques.

3. The advantages of Spray Paint guns

a. Material and surface versatility

Spray guns work on many different types of materials and surfaces, including wood, metal, plastic, glass, and more. Whether working on home DIY projects or industrial manufacturing, spray paint guns have the flexibility to apply to a variety of surfaces, delivering a consistent and even coating. This versatility makes the spray gun an ideal tool for diverse painting needs.

b. Wide choice of colors and finishes

Spray paint guns offer a wide range of colors and finishes to suit the needs of different projects and designs. Users can choose from different types of paints, including pigment paints, varnishes, metallic paints, and more, to achieve a variety of effects, from glossy to matte to metallic. This versatility makes spray guns ideal for creative and custom projects, meeting both industry standards and individual needs.

c. Simple and easy to use

Spray paint guns are generally designed to be simple and easy to use. They are equipped with easy-to-operate triggers and adjustments, making it easy for the operator to master the painting process. In addition, many modern spray guns are equipped with nozzle and air pressure adjustments that allow users to easily adjust the spray pattern and coating thickness to obtain the desired coating effect.

d. Add additives and fillers

Additives and fillers are used to improve the properties of coatings. Additives can include flow agents, antioxidants, anti-UV agents, etc., to improve the fluidity, weather resistance and anti-aging properties of the coating. Fillers are often used to increase the thickness and hardness of coatings, especially for some industrial applications. The types and proportions of additives and fillers added will vary depending on the desired coating properties.

4. The disadvantages of Spray Paint guns

a. Volatile organic emissions

Spray guns produce organic emissions during the spraying process, mainly from the solvents used in spraying and volatile organic compounds (VOCs) in the paint. These organic emissions may pose potential risks to the environment and human health. Although some modern paints and spray guns are designed to reduce the release of VOCs, careful handling and proper ventilation are still required to reduce environmental impact.

b. Over spray and material waste

Using a spray gun without paying attention to coating thickness and spray distance can result in overspray and wasted material. Over spraying not only wastes paint, it can also lead to poor coating quality, uneven surfaces, and may even cause environmental and health concerns. Operators need to have certain experience and skills to ensure uniform and appropriate thickness of the coating during spraying, thereby reducing waste.

c. Reduced durability

Over time, parts of a paint gun can become subject to wear and corrosion, causing its durability to decrease. Particularly when corrosive or sticky coatings are used, component life may be shorter. This may require regular maintenance and replacement of critical components, increasing operating costs and maintenance time.

5. Main Differences in Applications

a. Initial equipment investment cost

Powder spray gun: The equipment investment cost of the powder spray system is relatively high, including electrostatic spray equipment, spray booths and related exhaust gas treatment systems. The acquisition and installation of these systems may require significant capital investment.

Paint spray gun: The equipment investment cost of the paint spray system is relatively low, mainly including the spray booth and ventilation system. This makes paint spraying more economical in terms of initial investment.

b. Raw material utilization rate

Powder spray gun: The raw material of powder spraying is mainly powder coating, and its utilization rate is high. Since no solvent is evaporated during spraying, the waste of paint is reduced and the utilization efficiency of raw materials is improved, thereby achieving better cost-effectiveness in the coating process.

Paint spray gun: The raw materials for paint spraying are mainly liquid paints, some of which contain volatile organic solvents. During the spraying process, a certain amount of solvent may evaporate, resulting in paint waste and affecting the utilization efficiency of raw materials.

c. Safety of operation process

Powder spray guns: Relatively safer because no volatile organic solvents are involved, reducing the risk of fires and explosions.

Paint spray guns: Involve volatile organic solvents, which present a risk of fire and explosion and require special safety measures.

d. Convenience of spraying

Powder spray gun: Spraying is convenient and can achieve faster coating speed, especially suitable for uniform coating of large areas.

Paint spray gun: Spraying is more flexible and can achieve more detailed coating. It is suitable for applications requiring high precision.

e. Production efficiency

Powder spray gun: usually has high production efficiency and is especially suitable for mass production.

Paint spray guns: In some applications more coats and longer drying times may be required, affecting productivity.

f. Durability of coating

Powder spray guns: The coatings produced are usually highly resistant to corrosion and abrasion.

Paint Spray Gun: The durability of the coating depends on the type of paint used, and some paints may wear off easily over time.

Powder spray guns and paint spray guns play a major role in their respective spray fields. It is difficult to summarize whose performance is better in one sentence. For different coating effects and coating substrates, we need to make the right choice based on the actual situation. If you want long-term, stable coatings that can handle harsh outdoor conditions, then a powder coating gun is your first choice. If you want a flashier look, then a paint spray gun is better for you.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?