Safety precautions when using powder spray guns

There are also certain risks during the use of powder coating guns. If they are operated illegally or if corresponding protective measures are not taken, serious production accidents may occur. So do you know enough about the correct use of powder coating guns? When an accident occurs while spraying powder coating, do you have enough experience to solve it? After reading this article, you will have a systematic and comprehensive understanding of the safety precautions for powder coating guns.

1. Personal Protective Equipment (PPE)

In the dynamic world of powder coatings, personal protective equipment (PPE) does more than just comply; it’s the operator’s frontline defense against potential hazards.

a. The importance of wearing appropriate personal protective equipment

Understanding the seriousness of the potential risks, we emphasize the importance of wearing the correct personal protective equipment. From respiratory protection to ensuring eye and skin safety. Careful protection at every step can ensure the personal health of powder coating gun operators.

b. Basic safety equipment for operators

Operators are the backbone of any powder coating operation and their safety is non-negotiable. Get an in-depth look at the ins and outs of essential safety gear tailored for operators. From specialized glasses to protect against particles to ergonomic gloves designed for comfort and protection, we recommend sourcing essential safety gear for your operators.

2. Work environment safety

a. Proper ventilation and air quality

In powder coating facilities, proper ventilation and air quality management are essential. In the powder coating operation workshop, it is necessary to be equipped with sufficient ventilation equipment to ensure that dust and confusion will not occur in the operation workshop.

b. Firefighting measures

Dust explosions may occur when open flames or electric sparks are encountered in dusty workshops. This sudden and severe fire situation requires adequate fire protection measures to prevent and eliminate it. Regular inspections of fire escapes, fire extinguishers, and fire alarm systems ensure they are functioning properly in the event of a fire in the powder coating workshop.

3. Electrical Safety

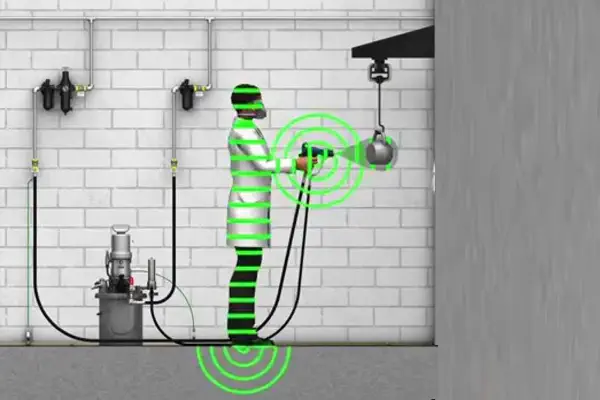

a. Grounding and electrostatic discharge

The application of powder coating originally relied on static electricity to adsorb powder to the workpiece. When working, the electrostatic spray gun will generate a large amount of static electricity, and the accumulated static electricity may cause major accidents. Therefore, all electrical equipment in the powder coating workshop needs to be grounded to ensure the safety of electrostatic discharge in the operating environment.

b. Maintenance of powder coating baking and curing oven

Since the powder coating baking and curing oven has been exposed to high temperature working environment for a long time, its internal wire circuit may cause poor contact or virtual soldering. Temperature sudden changes in the baking oven will cause serious harm to it and will also prevent the corresponding powder coating effect from being baked. Regular maintenance and upkeep as well as circuit equipment inspections can effectively solve the above problems.

4. Emergency preparation

a. Develop an emergency plan

Having a strong contingency plan is the foundation of effective crisis management. Developing effective emergency plans for various possible emergencies can greatly reduce losses after an accident. Regular emergency rescue drills can enable operators to have enough experience to deal with emergencies and will not be confused in the face of real accidents.

b. First aid and medical assistance

After an accident occurs, personal injury and property damage are inevitable. In order to minimize losses, we need to maintain contact with the medical assistance department at all times. Powder coating operators also need to be trained on first aid knowledge in daily personnel training courses so that the medical rescue team can perform emergency self-rescue before they arrive at the accident scene.

When powder coating and operating a powder coating gun, the safety of the operator is the first priority. Measures such as the provision of professional personal protective equipment, a safe powder coating operation workshop environment, regular electrical equipment safety inspections, and emergency self-rescue skills training can effectively ensure the safety of the entire powder coating process. The safety precautions for these powder coating guns cannot be ignored for various reasons and should always be vigilant and preventive.

Have Anything To Ask Us?