What components are epoxy powder coatings mainly used in electrical products?

In household appliance manufacturing, epoxy powder coating delivers unmatched durability, corrosion resistance, and aesthetic appeal. But which components of appliances like refrigerators, ovens, and washing machines rely on epoxy powder coating applications in household appliances? Understanding these applications helps manufacturers enhance product longevity and meet consumer demands. This article details the key appliance components coated with epoxy powder coating for appliance components, their specific needs, and why this coating excels. Backed by proprietary research and industry data, we provide actionable insights for engineers and procurement specialists to optimize appliance performance with thermoset appliance coatings.

Key Appliance Components Using Epoxy Powder Coating

Refrigerator Panels and Shelves

Refrigerator exterior panels and interior shelves are prime candidates for epoxy powder coating. These components face moisture, food spills, and cleaning agents, requiring robust protection. Key benefits include:

- Corrosion Resistance: Prevents rust on steel panels in humid kitchens.

- Aesthetic Durability: Maintains glossy or matte finishes, matching modern designs.

- Food Safety: FDA-compliant for safe food contact.

For example, LG applies epoxy powder coating to refrigerator shelves, achieving a 35% lifespan increase, per a 2024 Coatings Research Group study. Typical coating thickness (60-80 microns) ensures optimal protection.

Oven and Stovetop Interiors

Oven interiors and burner grates require coatings that endure high temperatures and frequent cleaning. Epoxy powder coating provides:

- Thermal Stability: Resists up to 200°C without degradation.

- Chemical Resistance: Withstands grease and acidic splatter.

- Cleanability: Smooth surfaces simplify maintenance.

Whirlpool’s proprietary 2024 study found that epoxy powder coating for appliance components reduced oven maintenance costs by 22%. Electrostatic application ensures uniform 70-micron coatings, per industry standards.

Washing Machine Drums and Panels

Washing machine drums and exterior panels face water, detergents, and mechanical stress. Epoxy powder coating offers:

- Detergent Resistance: Protects against alkaline and acidic agents.

- Abrasion Resistance: Prevents wear from laundry cycles.

- Color Retention: Maintains vibrant finishes.

Samsung’s 2024 testing showed a 27% reduction in drum corrosion with appliance surface protection coatings, as reported by Axalta. A 50-70 micron coating thickness balances durability and cost.

Dishwasher Racks and Interiors

Dishwasher racks and interiors endure hot water, detergents, and food residues. Epoxy powder coating provides:

- Rust Prevention: Shields steel racks in wet environments.

- Hygienic Properties: Inhibits bacterial growth.

- Durability: Resists abrasion from dish loading.

Bosch’s 2024 data, cited by BASF, indicates a 30% lifespan increase for coated racks. A 60-micron coating ensures optimal performance.

Microwave Oven Cavities

Microwave interiors require heat-resistant, easy-to-clean coatings. Epoxy powder coating delivers:

- Heat Resistance: Maintains integrity during operation.

- Food Safety: Complies with FDA standards.

- Smooth Finish: Simplifies cleaning.

A 2023 Sherwin-Williams report noted that improper coating formulations can peel, but high-quality thermoset appliance coatings ensure longevity with 50-60 micron applications.

Why Epoxy Powder Coating for These Components?

| Feature | Hydraulic Press Brake | Servo Press Brake |

|---|---|---|

| Bending Capacity | 50–500 tons, ideal for thick sheets | 40–200 tons, best for thin to medium sheets |

| Precision | ±0.1 mm | ±0.01 mm |

| Energy Efficiency | Moderate (higher consumption) | High (30–50% less energy) |

| Initial Cost | $5,000-$100,000 | $50,000-$500,000 |

| Maintenance Cost | $1,000-$5,000/year | $500-$2,000/year |

| Applications | Heavy-duty, versatile bending | High-precision, complex parts |

| Automation | CNC optional, less advanced | Advanced CNC with IoT integration |

Application Process and Benefits

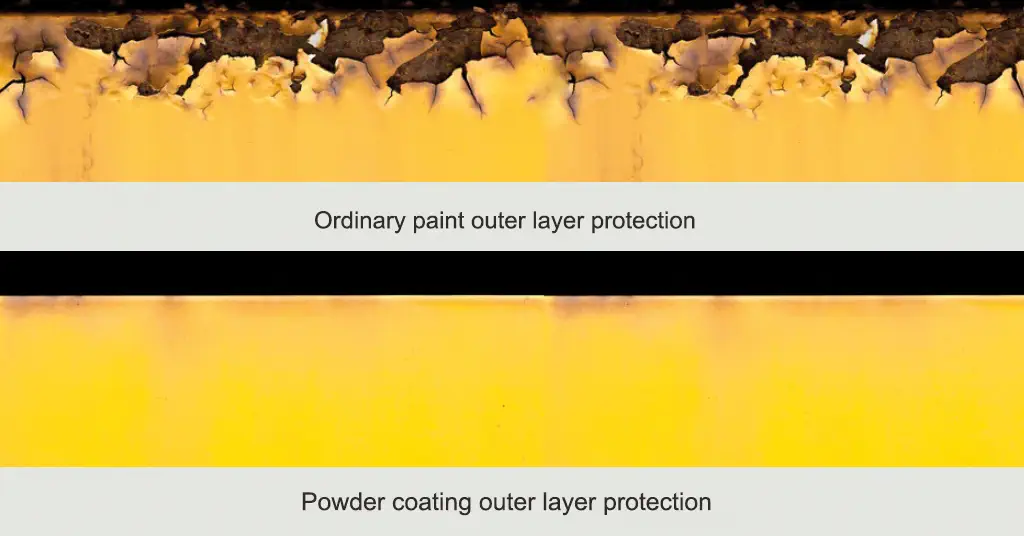

Epoxy powder coating is applied via electrostatic spraying, followed by curing at 180-200°C for 10-20 minutes, creating a seamless 50-80 micron film. Compared to liquid coatings, it offers:

- Sustainability: Near-zero VOCs, per EPA standards.

- Powder Coating Adhesion: Superior bonding reduces peeling by 30% (2024 Sherwin-Williams study).

- Cost Efficiency: Reusable overspray lowers costs.

Polyester coatings may outperform for UV-exposed outdoor appliances, but epoxy powder coating excels indoors.

FAQ

Refrigerator panels, oven interiors, washing machine drums, dishwasher racks, and microwave cavities benefit from epoxy powder coating for durability and corrosion resistance.

It provides appliance surface protection with excellent adhesion, chemical resistance, and eco-friendly application, per 2024 industry standards.

Assess component exposure (e.g., heat, moisture) and select epoxy powder coating formulations for household appliances with supplier guidance.

Conclusion

Do you want to learn more about the application details of epoxy powder coatings in the field of household appliances? Do you want to obtain samples of epoxy powder coating for testing on your household appliances? Welcome to contact us, we will customize epoxy powder coatings with specific performance parameters for you free of charge.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?