How Do Epoxy Coatings Insulate EV Battery Packs for Safety?

Electric vehicle (EV) battery packs are critical components that store and deliver high-voltage energy, requiring robust insulation to ensure safety, reliability, and performance. Epoxy powder coatings are increasingly used to insulate battery packs due to their high dielectric strength, thermal stability, and durability. This article explores how epoxy coatings provide electrical insulation for EV battery packs, their benefits, key considerations, and best practices for safe and effective insulation. Designed for engineers, EV manufacturers, and industry professionals, this guide offers actionable insights to enhance battery pack safety.

Why Insulation Is Critical for EV Battery Packs

EV battery packs operate at high voltages (typically 300–800V) and generate significant heat, making electrical insulation essential to:

- Prevent Short Circuits: Insulation isolates cells, modules, and busbars to avoid unintended electrical connections.

- Reduce Arcing Risks: High dielectric strength prevents electrical arcs that could ignite flammable electrolytes.

- Protect Against Environmental Hazards: Insulation shields components from moisture, dust, and chemicals, common in automotive environments.

- Ensure Passenger Safety: Robust insulation minimizes the risk of electrical shocks or fires, critical for consumer safety.

- Extend Battery Life: Effective insulation reduces electrical leakage, maintaining efficiency and longevity.

Epoxy powder coatings address these needs by providing a durable, high-performance insulating layer tailored to the unique demands of EV battery packs.

How Epoxy Coatings Insulate EV Battery Packs

1. High Dielectric Strength

Epoxy powder coatings offer dielectric strengths of 10–50 kV/mm, enabling them to withstand the high voltages in EV battery packs. For example:

- Cell-to-Cell Insulation: Thin coatings (200–500 µm) applied to battery cell casings prevent leakage between adjacent cells.

- Busbar Insulation: Thicker coatings (1,000–2,000 µm) on high-voltage busbars ensure breakdown voltages up to 50 kV, critical for connecting battery modules.

- Module Enclosures: Coatings on metal enclosures (e.g., aluminum) provide insulation against external grounding, reducing shock risks.

Example: SolEpoxy’s DK15-0907 coating, with a dielectric strength of 30 kV/mm, achieves a breakdown voltage of 15 kV at 500 µm, sufficient for insulating 400V battery busbars.

2. Thermal Management

EV battery packs generate heat during charging and discharging, often reaching 60–80°C or higher. Epoxy coatings with thermal stability up to Class F (155°C) or Class H (180–200°C) maintain insulation integrity under these conditions, preventing dielectric breakdown or material degradation.

- Heat Dissipation: Some epoxy formulations incorporate thermally conductive fillers to aid heat transfer while maintaining electrical insulation, protecting cells from thermal runaway.

- Thermal Cycling Resistance: Epoxy coatings withstand repeated heating and cooling cycles without cracking, ensuring long-term reliability.

3. Environmental Protection

EV battery packs are exposed to harsh conditions, including humidity, road salts, and chemicals. Epoxy coatings provide:

Moisture Resistance: Hydrophobic formulations block water ingress, preventing corrosion or electrical leakage in humid environments (e.g., >85% RH).

- Chemical Resistance: Protects against electrolyte spills, oils, or cleaning agents, common in automotive settings.

- Corrosion Protection: Insulates metal components like aluminum or copper busbars, preventing oxidation that could compromise insulation.

Example: CAPLINQ’s Hysol DK Series coating, applied to battery enclosures, maintained dielectric strength after 1,000 hours of salt spray testing per ASTM B117.

4. Mechanical Durability

Battery packs endure vibrations, impacts, and mechanical stress during vehicle operation. Epoxy coatings offer:

- Abrasion Resistance: Protects against scratches or wear during assembly or maintenance.

- Impact Resistance: Maintains insulation integrity under physical stress, critical for crash safety.

- Adhesion: Strong bonding to substrates like aluminum, steel, or composites ensures long-term performance.

Best Practice: Use abrasive blasting or primers to enhance adhesion on battery enclosures, ensuring coatings withstand automotive vibrations.

Applications of Epoxy Coatings in EV Battery Packs

Epoxy powder coatings are applied to various battery pack components to enhance safety and performance:

- Battery Cells: Thin coatings (200–300 µm) on cell casings or separators prevent short circuits between cells.

- Busbars: Thick coatings (1,000–2,000 µm) insulate high-voltage connections, reducing arcing risks.

- Module Enclosures: Coatings on aluminum or steel housings provide external insulation and corrosion protection.

- Cooling Plates: Insulated coatings on thermal management systems prevent electrical leakage while allowing heat transfer.

- Connectors and Terminals: Coatings on high-voltage connectors ensure insulation under mechanical and environmental stress.

Benefits of Epoxy Coatings for EV Battery Insulation

- High Dielectric Strength: Prevents electrical breakdown at voltages up to 800V, ensuring safety in high-power EV systems.

- Thermal Stability: Maintains insulation at operating temperatures up to 155–200°C, critical for fast-charging or high-performance EVs.

- Environmental Resistance: Protects against moisture, chemicals, and corrosion, extending battery pack lifespan.

- Mechanical Durability: Resists vibrations, impacts, and abrasion, ideal for automotive environments.

- Eco-Friendly Application: Solvent-free powder coatings reduce VOC emissions, supporting sustainable manufacturing.

- Customizable Thickness: Adjustable from 200 µm to 5,000 µm to meet specific voltage and insulation needs.

Key Factors for Choosing Epoxy Coatings for EV Battery Packs

- Voltage Requirements: Match dielectric strength to the battery pack’s operating voltage (e.g., 30 kV/mm for 400–800V systems).

- Thermal Conditions: Choose Class F or H coatings for temperatures above 130°C, common in fast-charging or high-performance EVs.

- Environmental Exposure: Select moisture- and chemical-resistant formulations for humid or corrosive environments.

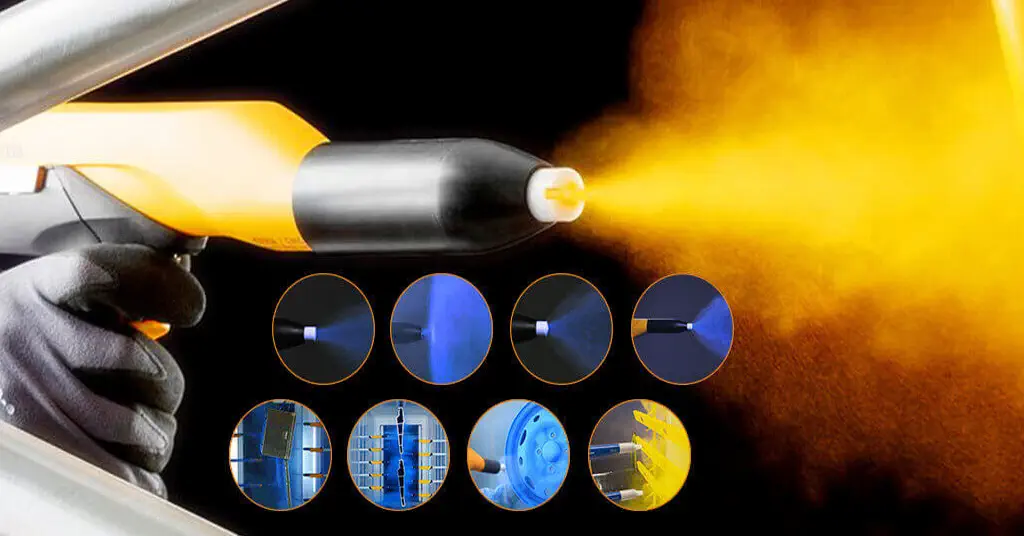

- Application Method: Use electrostatic spraying for thin, uniform coatings on cells or fluidized bed dipping for thicker busbar insulation.

- Substrate Compatibility: Ensure strong adhesion to aluminum, steel, or composites via proper surface preparation.

- Regulatory Compliance: Meet standards like UL 94 V-0 (flame resistance) and IEC 60243 (dielectric strength) for automotive safety.

Comparison with Other Insulation Materials

| Material | Dielectric Strength | Max Temp (°C) | Key Advantages | Key Limitations |

|---|---|---|---|---|

| Epoxy Powder Coating | 10–50 kV/mm | 155–200 | High dielectric, durable, eco-friendly | Limited above 200°C, application precision |

| Silicone-Based Coating | 5–20 kV/mm | 550+ | Extreme heat resistance, flexible | Lower dielectric strength, higher cost |

| Polyurethane Coating | 5–15 kV/mm | 130–150 | Flexible, lightweight | Less durable, limited thermal stability |

| Ceramic Coating | Varies | 1,800 | Extreme temp resistance, chemical inert | Brittle, heavy, expensive |

Top Epoxy Powder Manufacturers for EV Battery Insulation

| Manufacturer | Product Line | Dielectric Strength | Max Temp (°C) | Key Features |

|---|---|---|---|---|

| SolEpoxy | DK15-0907 | 30 kV/mm | 180 | High-voltage insulation, thermal stability |

| PPG Coatings | Corvel Series | 25–35 kV/mm | 155–180 | Moisture and chemical resistance |

| CAPLINQ | Hysol DK Series | 20–40 kV/mm | 130–200 | RoHS-compliant, high adhesion |

| ThreeBond | TB Series | 15–30 kV/mm | 130–155 | Vibration-resistant, easy application |

Conclusion

Epoxy powder coatings play a vital role in insulating EV battery packs, providing high dielectric strength, thermal stability, and environmental protection to ensure safety and performance. By insulating cells, busbars, and enclosures, these coatings prevent short circuits, arcing, and electrical shocks while extending battery life. Selecting the right coating thickness, formulation, and application method, combined with rigorous quality control, is essential for reliable insulation in high-voltage EV systems.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?