Does Humidity Affect Epoxy Powder's Electrical Insulation?

Epoxy powder coatings are widely used for electrical insulation in components like transformers, busbars, and motors due to their high dielectric strength and durability. However, environmental factors such as humidity can influence their performance. This article explores how humidity affects the electrical insulation properties of epoxy powder coatings, key considerations for humid environments, and best practices to ensure reliable insulation. Whether you’re an engineer, manufacturer, or industry professional, this guide provides actionable insights to maintain insulation integrity in challenging conditions.

Understanding Epoxy Powder Coatings for Electrical Insulation

Epoxy powder coatings are thermosetting powders applied as a dry material that melts and cures to form a robust, insulating layer. Known for their high dielectric strength (1,000–50,000 volts), chemical resistance, and thermal stability (up to 200°C in specialized formulations), they are ideal for insulating electrical components. However, their performance can be impacted by environmental factors like humidity, which may compromise dielectric strength, adhesion, or long-term reliability if not properly addressed.

How Humidity Affects Epoxy Powder Coatings

1. Impact on Dielectric Strength

High humidity can reduce the dielectric strength of epoxy powder coatings by allowing moisture to penetrate the coating or substrate interface. Moisture acts as a conductor, increasing the risk of electrical leakage, arcing, or breakdown. Studies show that uncoated or poorly formulated epoxy coatings exposed to relative humidity (RH) above 85% may experience a 10–20% reduction in dielectric strength over time.

- Example: A standard epoxy coating with a dielectric strength of 30 kV/mm at 50% RH may drop to 24 kV/mm at 90% RH if not formulated for moisture resistance.

- Key Factor: The coating’s ability to resist moisture ingress depends on its formulation, thickness, and application quality.

2. Surface Contamination and Adhesion Issues

Humidity can introduce contaminants like dust or condensation on the substrate before coating, leading to poor adhesion. This creates voids or weak spots where moisture can accumulate, further degrading insulation performance. For instance, applying epoxy powder to a busbar in a humid environment (RH > 70%) without proper surface preparation can result in delamination, reducing insulation effectiveness.

3. Long-Term Degradation

Prolonged exposure to high humidity can cause hydrolysis in poorly formulated epoxy coatings, where water molecules break down the polymer structure. This leads to:

Cracking or blistering of the coating.

- Reduced dielectric strength and mechanical durability.

- Increased susceptibility to corrosion, especially on metal substrates like copper or aluminum.

Specialized epoxy powders with hydrophobic additives or enhanced cross-linking can mitigate these effects, maintaining insulation integrity in humid conditions.

4. Thermal-Humidity Synergy

High humidity combined with elevated temperatures (e.g., in tropical climates or near heat-generating components like transformers) accelerates degradation. For example, at 40°C and 90% RH, epoxy coatings may experience faster moisture absorption, reducing dielectric strength more rapidly than at room temperature.

Applications Vulnerable to Humidity

Epoxy powder coatings are used in environments where humidity can pose challenges, including:

- Outdoor Power Distribution: Busbars and switchgear exposed to rain or high RH in coastal areas.

- Marine Electronics: Components on ships or offshore platforms facing saltwater and humidity.

- Tropical Industrial Settings: Motors and transformers in factories with poor climate control.

- HVAC Systems: Capacitors and PCBs in humid indoor environments.

- Renewable Energy: Wind turbines or solar inverters exposed to fluctuating weather conditions.

Case Study: A solar inverter manufacturer in Southeast Asia reported insulation failures in standard epoxy-coated PCBs at 95% RH. Switching to a moisture-resistant epoxy powder from CAPLINQ (Hysol DK Series) improved dielectric performance by 25%, eliminating failures.

Factors Influencing Humidity Resistance

1. Coating Formulation

Epoxy powders formulated for humidity resistance include:

- Hydrophobic Additives: Repel water to minimize moisture absorption.

- High Cross-Linking Density: Creates a denser, less permeable coating to block water ingress.

- Corrosion Inhibitors: Protect metal substrates from rust or oxidation in humid conditions.

Example: SolEpoxy’s DK15-0607 powder is designed for high-humidity environments, maintaining dielectric strength of 25 kV/mm at 90% RH.

2. Coating Thickness

Thicker coatings (e.g., 1,000–5,000 microns) provide better moisture barriers, ideal for high-voltage applications in humid environments. However, excessively thick coatings may crack under thermal cycling if not properly cured.

- Recommendation: For outdoor busbars in humid climates, use fluidized bed dipping to achieve 1,200–2,000 microns with a dielectric strength of 20–30 kV/mm.

3. Application Method

The application method affects the coating’s ability to resist humidity:

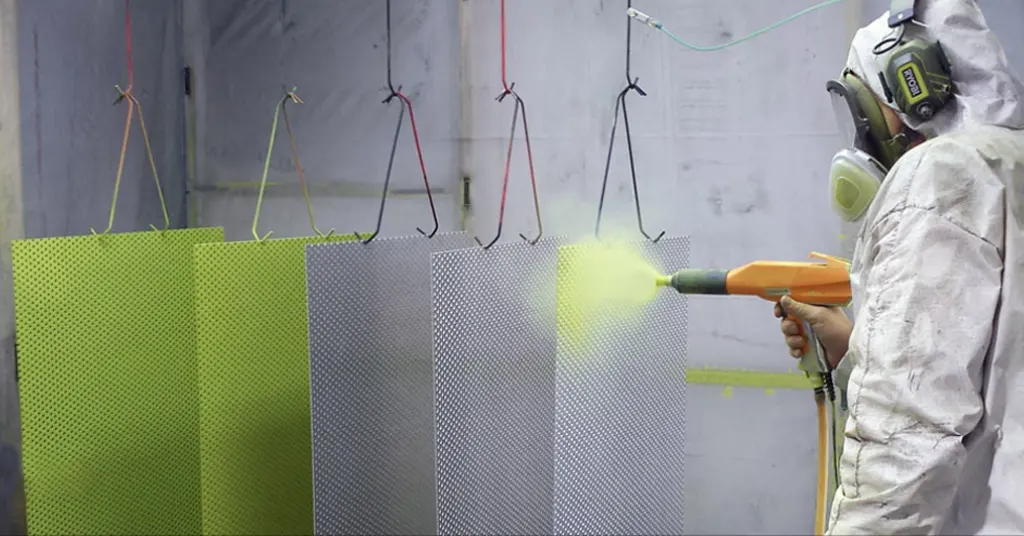

- Electrostatic Spraying: Produces thin, uniform coatings (200–500 microns) suitable for low- to medium-voltage components but may require multiple layers in humid environments.

- Fluidized Bed Dipping: Creates thicker, seamless coatings for high-voltage components, offering superior moisture resistance.

Best Practice: Preheat substrates to 200–220°C before fluidized bed application to eliminate surface moisture and enhance adhesion.

4. Substrate Preparation

Proper surface preparation is critical in humid conditions:

- Cleaning: Remove oils, oxides, or contaminants using abrasive blasting or chemical degreasers.

- Drying: Ensure substrates are dry before coating to prevent trapped moisture.

- Primers: Apply corrosion-resistant primers on metal substrates like copper to enhance adhesion and humidity resistance.

Example: Storm Power Components uses abrasive blasting on aluminum busbars to improve epoxy adhesion in high-humidity applications.

5. Curing Process

Proper curing at 150–200°C ensures a dense, cross-linked coating that resists moisture penetration. Under-curing can leave the coating porous, while over-curing may cause brittleness, both reducing humidity resistance.

Tip: Use curing ovens with precise temperature control and verify curing completion with dielectric strength tests.

Best Practices for Using Epoxy Powder in Humid Environments

- Select Moisture-Resistant Formulations: Choose epoxy powders with hydrophobic properties and high cross-linking, such as PPG’s Corvel Series or SolEpoxy’s DK15-0607.

- Optimize Coating Thickness: Use thicker coatings (1,000+ microns) for high-voltage components in humid climates, applied via fluidized bed dipping.

- Ensure Proper Surface Preparation: Clean and dry substrates thoroughly, using primers if needed, to prevent adhesion issues.

- Control Application Environment: Apply coatings in climate-controlled facilities with RH below 60% to avoid contamination or condensation.

- Test for Humidity Resistance: Conduct accelerated aging tests (e.g., 85°C/85% RH per IEC 60068) to validate dielectric strength in humid conditions.

- Monitor Performance: Use dielectric strength testers (e.g., Megger MIT525) to periodically check insulation integrity in field applications.

Comparison with Other Insulation Materials

| Material | Humidity Resistance | Dielectric Strength | Key Advantages | Key Limitations |

|---|---|---|---|---|

| Epoxy Powder Coating | Good (with formulation) | 1,000–50,000V | Durable, cost-effective, high dielectric | May degrade at extreme RH without additives |

| Silicone-Based Coating | Excellent | 500–20,000V | Superior moisture resistance, flexible | Lower dielectric strength, higher cost |

| Polyurethane Coating | Moderate | 1,000–15,000V | Flexible, good adhesion | Limited thermal stability, less durable |

| Ceramic Coating | Excellent | Varies | Extreme humidity and temp resistance | Brittle, expensive, complex application |

| Epoxy powder coatings offer a balanced solution for humid environments when formulated for moisture resistance, outperforming polyurethane and rivaling silicone in cost-effectiveness. | ||||

Top Epoxy Powder Manufacturers for Humidity Resistance

| Manufacturer | Product Line | Dielectric Strength | Humidity Resistance | Key Features |

|---|---|---|---|---|

| SolEpoxy | DK15-0607 | 25 kV/mm | High | Hydrophobic, high adhesion |

| PPG Coatings | Corvel Series | 20–30 kV/mm | High | Chemical and moisture resistance |

| CAPLINQ | Hysol DK Series | 20–35 kV/mm | Moderate to High | RoHS-compliant, durable |

| ThreeBond | TB Series | 15–25 kV/mm | Moderate | Easy application, corrosion-resistant |

Conclusion

Humidity can affect the electrical insulation properties of epoxy powder coatings by reducing dielectric strength, causing adhesion issues, or leading to long-term degradation. However, with moisture-resistant formulations, proper application techniques, and rigorous quality control, epoxy powders remain a reliable choice for insulating components in humid environments. By selecting the right coating, optimizing thickness, and following best practices, you can ensure safety, reliability, and longevity in applications like transformers, busbars, and marine electronics.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?