How to Choose the Right Epoxy Powder Coating for Your Metal Surfaces

When it comes to protecting and enhancing the appearance of metal surfaces, epoxy powder coating is a popular choice. This durable and versatile coating offers excellent adhesion, corrosion resistance, and a sleek finish. However, with various options available, selecting the right epoxy powder coating can be challenging. This guide will walk you through the key factors to consider to ensure you choose the best coating for your needs.

Understanding Epoxy Powder Coating

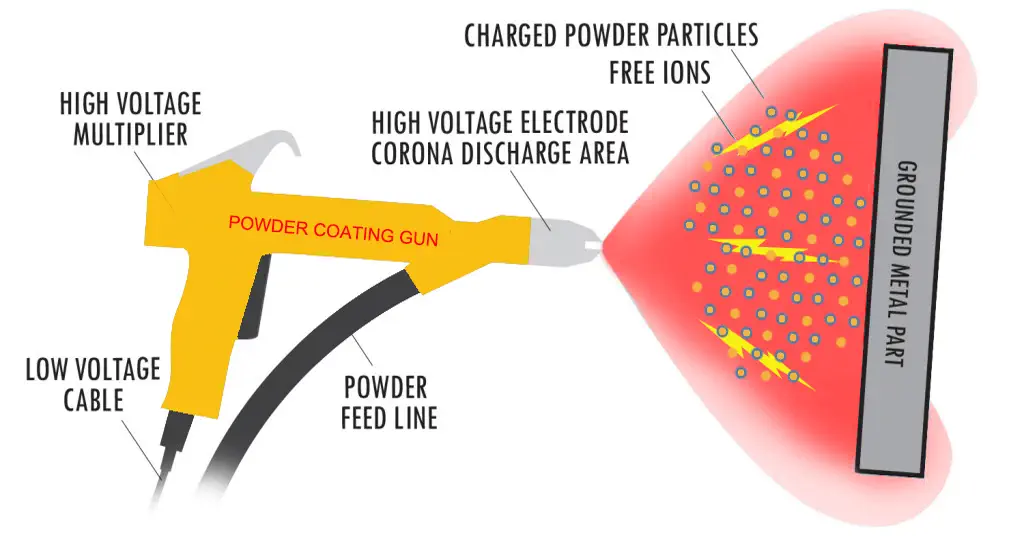

Epoxy powder coating is a type of protective finish applied as a free-flowing, dry powder. Unlike conventional liquid paint, it is applied electrostatically and then cured under heat to form a hard, durable layer. This process not only provides a uniform finish but also minimizes waste and environmental impact.

How Epoxy Powder Coating Works to Prevent Corrosion

Key Benefits of Epoxy Powder Coating

- Durability: Epoxy coatings are known for their exceptional durability and resistance to wear and tear.

- Corrosion Resistance: They provide excellent protection against rust and corrosion, making them ideal for metal surfaces exposed to harsh environments.

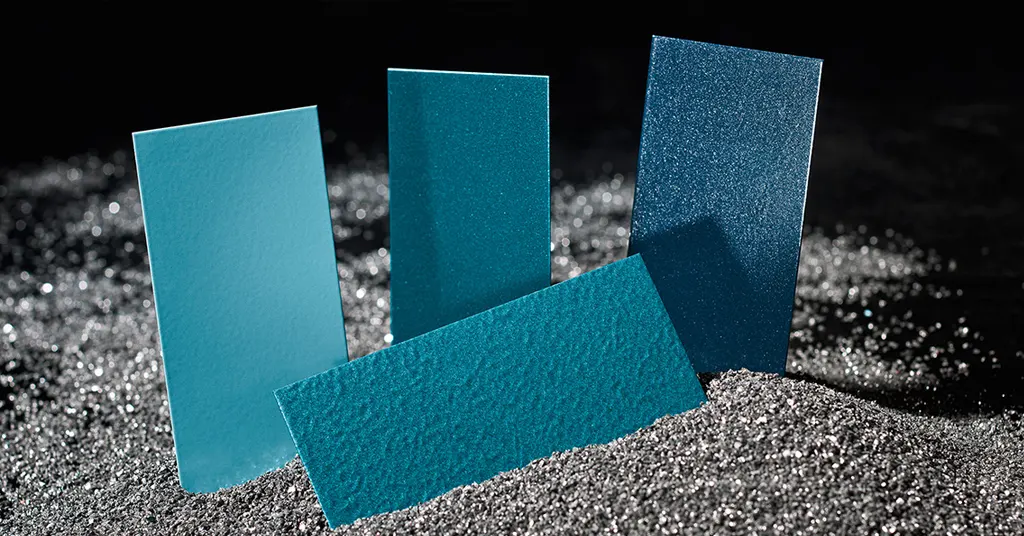

- Aesthetic Appeal: Available in a wide range of colors and finishes, epoxy powder coatings can enhance the visual appeal of metal surfaces.

- Environmental Friendliness: The powder coating process produces minimal volatile organic compounds (VOCs), making it an eco-friendly option.

Factors to Consider When Choosing Epoxy Powder Coating

1. Surface Preparation

Proper surface preparation is crucial for the success of any powder coating application. Ensure the metal surface is clean, dry, and free from contaminants such as oil, grease, and rust. Techniques like sandblasting or chemical treatments can be used to achieve the desired surface profile.

2. Environmental Conditions

Consider the environmental conditions the coated surface will be exposed to. For instance, if the metal will be outdoors, choose a coating with UV resistance to prevent fading and degradation. For industrial environments, opt for coatings with high chemical resistance.

3. Application Method

The method of application can affect the performance and appearance of the coating. Common methods include electrostatic spray, fluidized bed, and electrostatic fluidized bed. Each method has its advantages and is suitable for different types of projects.

4. Curing Process

The curing process is essential for achieving the desired properties of the coating. Ensure you have the appropriate equipment and follow the manufacturer’s guidelines for temperature and time to achieve optimal results.

5. Color and Finish

Epoxy powder coatings come in a variety of colors and finishes, including matte, gloss, and textured. Choose a color and finish that not only meets your aesthetic preferences but also complements the functional requirements of the coated surface.

6. Compliance and Certifications

Ensure the epoxy powder coating complies with relevant industry standards and certifications. This is particularly important for applications in industries like automotive, aerospace, and food processing, where specific regulations must be met.

Conclusion

Choosing the right epoxy powder coating for your metal surfaces involves careful consideration of various factors, including surface preparation, environmental conditions, application methods, and curing processes. By taking these factors into account, you can ensure a durable, attractive, and long-lasting finish that meets your specific needs.

Have Anything To Ask Us?