How Epoxy Powder Coating Enhances Corrosion Resistance in Harsh Environments

Corrosion is a major challenge for metal surfaces exposed to harsh environments, such as high humidity, saltwater, or industrial chemicals. Epoxy powder coating has emerged as a leading solution to combat this issue, offering unparalleled protection and durability. In this article, we’ll explore how epoxy powder coating enhances corrosion resistance and why it’s the ideal choice for industries operating in demanding conditions.

Understanding Corrosion and Its Impact

Corrosion occurs when metal reacts with environmental factors like moisture, oxygen, and chemicals, leading to rust, degradation, and structural weakness. In harsh environments, such as coastal areas, industrial facilities, or outdoor installations, the risk of corrosion is significantly higher. This can result in costly repairs, reduced lifespan of equipment, and safety hazards.

How Epoxy Powder Coating Works to Prevent Corrosion

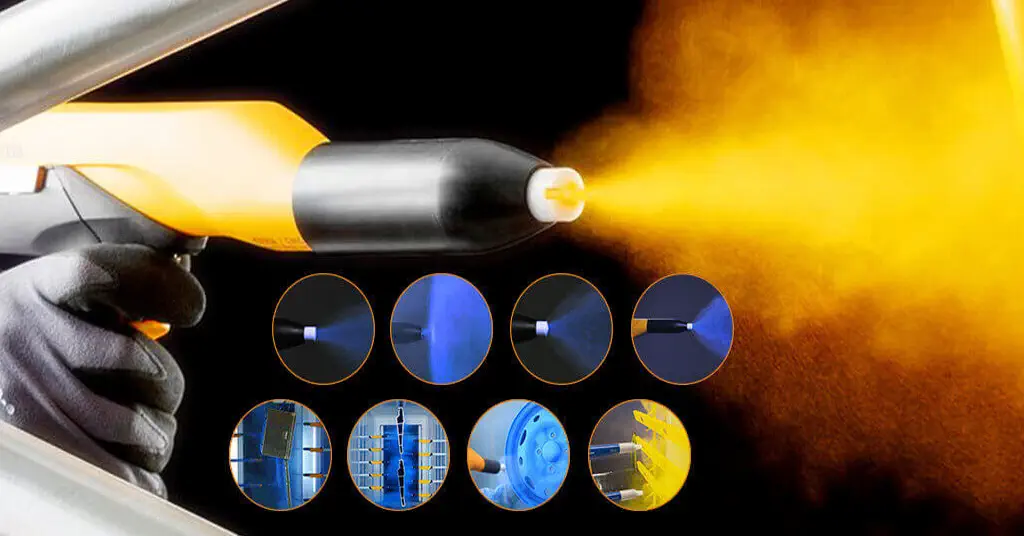

Epoxy powder coating is a dry finishing process where electrostatically charged powder is applied to a metal surface. The coated object is then cured under heat, forming a seamless, protective layer. Here’s how it enhances corrosion resistance:

1. Seamless Barrier Protection

Unlike traditional paints, epoxy powder coating creates a uniform, non-porous layer that prevents moisture, oxygen, and chemicals from reaching the metal surface. This barrier is key to stopping corrosion before it starts.

2. Excellent Adhesion

The electrostatic application ensures the powder adheres tightly to the metal, eliminating gaps or weak spots where corrosion could begin.

3. Chemical Resistance

Epoxy powder coatings are formulated to resist a wide range of chemicals, including acids, alkalis, and solvents. This makes them ideal for industrial environments where metal surfaces are exposed to corrosive substances.

4. UV and Weather Resistance

Specialized epoxy powders can withstand UV radiation and extreme weather conditions, making them suitable for outdoor applications like marine equipment or architectural structures.

5. Durability in High-Stress Environments

The tough, resilient finish of epoxy powder coating can endure physical stress, abrasion, and temperature fluctuations, ensuring long-term protection in harsh settings.

Marine Industry

Boats, ships, and offshore structures are constantly exposed to saltwater, which accelerates corrosion. Epoxy powder coating provides a durable, rust-resistant finish that extends the lifespan of marine equipment.

Oil and Gas Industry

Pipelines, drilling equipment, and storage tanks face exposure to corrosive chemicals and extreme temperatures. Epoxy powder coating ensures these critical components remain protected and functional.

Automotive Industry

Vehicles, especially in coastal or snowy regions, are prone to rust. Epoxy powder coating is used on undercarriages, wheels, and other metal parts to prevent corrosion and maintain performance.

Industrial Machinery

Manufacturing equipment exposed to chemicals, moisture, or high temperatures benefits from the protective properties of epoxy powder coating.

Infrastructure and Construction

Bridges, railings, and outdoor metal structures in harsh climates require finishes that can withstand weathering and corrosion. Epoxy powder coating delivers both protection and aesthetic appeal.

Advantages of Epoxy Powder Coating Over Other Methods

- Longer Lifespan: Epoxy powder coating outperforms traditional paints in terms of durability, often lasting decades without significant wear or corrosion.

- Eco-Friendly Solution: The solvent-free application process reduces environmental impact and minimizes health risks for workers.

- Cost-Effectiveness: While the initial investment may be higher, the long-term savings from reduced maintenance and repairs make epoxy powder coating a cost-effective choice.

- Customizable Finishes Epoxy powder coatings are available in a variety of colors, textures, and finishes, allowing for both functional and aesthetic customization.

Tips for Maximizing Corrosion Resistance with Epoxy Powder Coating

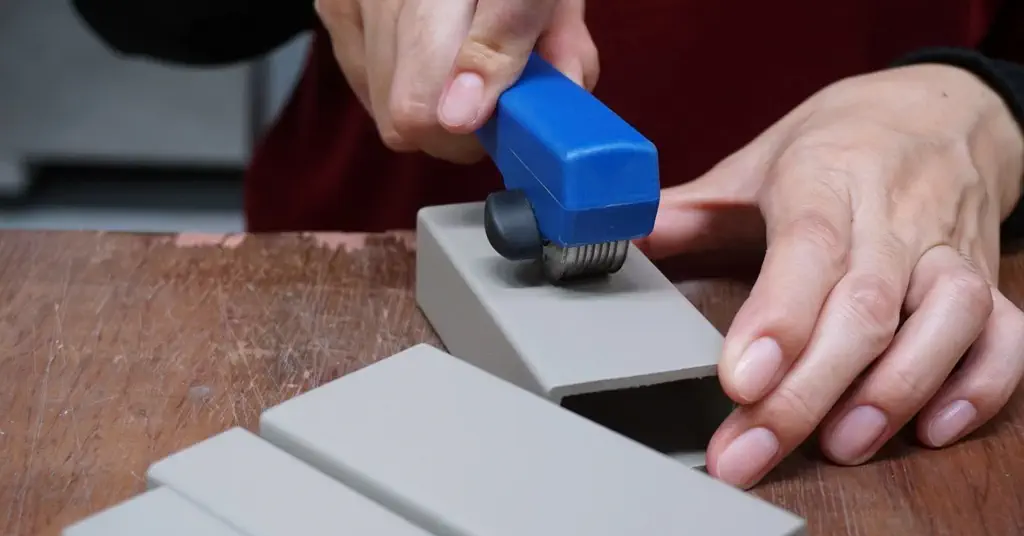

- Proper Surface Preparation: Thoroughly clean and prepare the metal surface by removing rust, grease, and old paint. Techniques like sandblasting or chemical treatments ensure optimal adhesion.

- Choose the Right Epoxy Formula: Select a powder specifically designed for your environment. For example, use a marine-grade epoxy for saltwater exposure or a chemical-resistant formula for industrial settings.

- Ensure Even Application: Use professional electrostatic equipment to apply the powder evenly, avoiding thin spots or gaps that could compromise protection.

- Follow Curing Guidelines: Adhere to the recommended curing temperature and time to ensure the coating achieves its full protective potential.

- Regular Inspections: Periodically check coated surfaces for signs of wear or damage. Address any issues promptly to maintain the coating’s effectiveness.

Real-World Examples of Epoxy Powder Coating Success

Offshore Wind Turbines: Epoxy powder coating protects turbine components from saltwater corrosion, ensuring reliable energy production in marine environments.

Chemical Storage Tanks: Industrial tanks coated with epoxy powder resist chemical corrosion, safeguarding hazardous materials and extending equipment life.

Coastal Infrastructure: Bridges and railings in coastal areas benefit from epoxy powder coating’s ability to withstand salt spray and humidity.

Conclusion

Epoxy powder coating is a proven solution for enhancing corrosion resistance in harsh environments. Its seamless barrier protection, chemical resistance, and durability make it an ideal choice for industries like marine, oil and gas, automotive, and construction. By investing in epoxy powder coating, you can protect your metal assets, reduce maintenance costs, and ensure long-term performance.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?