Epoxy Resin Powder Coating

Epoxy Resin Powder Coating

- Sample: Free Sample Supported

- Color : Customized Supported

- Gloss : 2-95% (Smooth Surface At 60°),Customized Supported

- Surface : Smooth Or Texture ; Customized Supported

- Package : 20KG Or 25KG/Carton Or Customized Supported

- Delivery : In 2-5 Days

Product Performance

- Great Chemical Resistance Performance

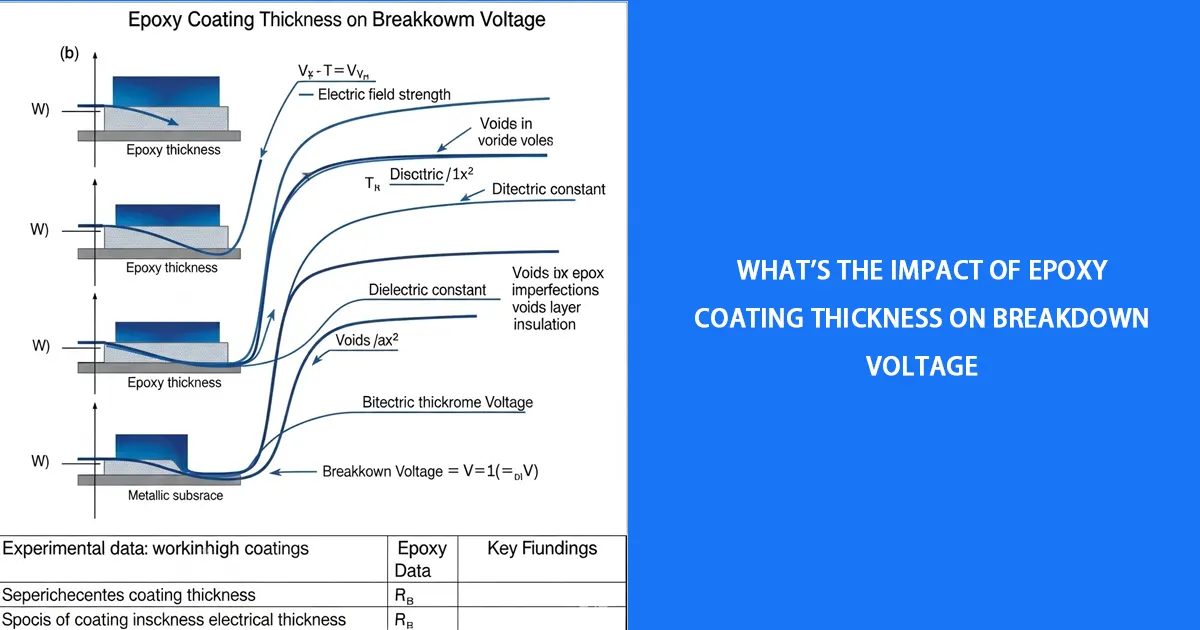

- Excellent Electric Insulation Property

- Excellent Anti Corrosive Property

- Excellent Mechanical And Anti-Corrosion Performance

- Great Leveling And Gloss

- Widely Usage Under Different Temperature Condition

Suitable For The Coating Of Metal Products With High Requirements For Corrosion Resistance, Electrical Insulation And Flexibility. Generally, It Is Not Recommended To Be Directly Used For The Surface Coating Of Various Outdoor Products.

| Density | 1.2-1.8 G/cm³ |

| Film | Film Thickness :40u~150um , Best Recommendation Is 40um~80um |

| Utilization Rate | Average Coverage : 10~12 Square Meter/KG ,With 60um (100% Use Rate) |

| Curing Condition | 140-200°C/15min; Or Customized According To Requirements |

| Method | Corona Electrostatic Spraying ,Electrostatic-Fluidized Bed, Fluidized Beds,Tribo Charging Guns |

| Applicaiton | Mainly Used For Indoor Appliance, Or Coating Of Aluminum/Copper Busbars, New Energy Vehicle Power Battery Shells, Controller Connectors, Motor Rotors, Stators, Transformers, Magnet Wires And Other Metal Substrates That Require High Insulation Performance ; And Single-Layer, Double-Layer And Three-Layer FBE Anticorrosive Coating Of Various Oil And Gas Steel Pipelines. |

| Transportation | Two Layers Of Polyvinyl Chloride Plastic Bags In Carton Package, 20 /25kg Per Carton. Non-Dangerous Goods Can Be Transported In Various Ways, But Avoild From Direct Sunlight, Moisture And Heat, And Contact With Chemical Substances. |

| Safety | Non Toxic Substances, And There Is No Toxic Gas Generated During Baking, But Avoid Inhaling Dust During Use, Operators Should Wear Dust Masks, And Minimize The Long-Term Contact Between Skin And Powder Coatings, Which Adhere To The Skin The Paint On The Surface Can Be Cleaned With Soap. |

Latest news

What is epoxy resin powder coating and how does it work?

Epoxy resin powder coating is a specialized coating process used to protect and enhance the appearance of various surfaces, particularly metal objects. It combines the benefits of epoxy resin and powder coating technology to create a durable, attractive finish. Here’s an overview of what epoxy resin powder coating is and how it works:

Epoxy Resin: Epoxy resins are thermosetting polymers that provide excellent adhesion, corrosion resistance, and chemical resistance when used as a coating material. They are often used in applications where durability is crucial.

Powder Coating: Powder coating is a dry finishing process that involves applying a fine powder made of various resin types, pigments, and additives to a substrate. The powder is electrostatically charged and sprayed onto the object to be coated, and then it is baked in an oven to create a smooth and durable finish.

Epoxy resin powder coating combines these two technologies in the following way:

Powder Preparation: Epoxy resin-based powder coatings are formulated by combining epoxy resin with appropriate pigments, fillers, and curing agents. The mixture is ground into a fine powder.

Surface Preparation: The substrate to be coated, usually metal, is cleaned and prepared to remove any contaminants, rust, or old coatings. This is essential to ensure good adhesion of the powder coating.

Powder Application: The epoxy resin powder is electrostatically charged and sprayed onto the prepared surface. The electrostatic charge causes the powder particles to adhere to the substrate evenly, forming a uniform layer.

Curing: The coated object is then heated in an oven. The heat activates the curing process of the epoxy resin. During curing, the epoxy molecules cross-link, creating a strong and chemically resistant coating. The curing temperature and time are carefully controlled to achieve the desired properties.

Cooling and Solidification: After curing, the coated object is allowed to cool down, and the epoxy resin solidifies, forming a hard, glossy, and durable finish.

What are the advantages of epoxy resin powder coating?

| Durability: Epoxy resin powder coatings are highly durable and can withstand harsh environmental conditions. They provide excellent resistance to corrosion, chemicals, and UV radiation. This durability ensures that the coated surfaces maintain their appearance and integrity over an extended period. | Chemical Resistance: Epoxy resin coatings are known for their resistance to a wide range of chemicals, including acids, bases, solvents, and oils. This makes them suitable for applications where exposure to corrosive substances is a concern. |

| Adhesion: Epoxy resin powder coatings adhere exceptionally well to various substrates, such as metal, ensuring a strong bond. This adhesion is vital for long-lasting protection and aesthetics. | Versatility: Epoxy resin powder coatings can be applied to a wide range of materials, including metals (such as steel and aluminum), wood, and some plastics. This versatility makes them suitable for various industries and applications. |

| Aesthetic Options: These coatings offer a smooth and attractive finish with a wide spectrum of color options and gloss levels. This allows for customization to achieve the desired visual appearance and texture. | Environmental Friendliness: Powder coating, in general, is an environmentally friendly process. It produces minimal or no volatile organic compounds (VOCs), reducing air pollution. The application process also generates less waste, as excess powder can be reclaimed and reused. |

| Cost-Effective: While the initial investment in powder coating equipment and materials may be higher than some traditional coating methods, the long-term cost benefits are significant. The durability of epoxy resin powder coatings reduces the need for frequent recoating and maintenance, ultimately saving money over time. | Fast Cure Times: Epoxy resin powder coatings typically have relatively short curing times in comparison to some liquid coatings. This can lead to increased productivity in manufacturing processes. |

| Impact Resistance: These coatings are known for their toughness and impact resistance. They can withstand physical impacts without chipping or cracking, which is essential in applications where the coated surface may experience mechanical stress. | Uniform Coating Thickness: The powder coating process provides uniform thickness across the entire surface, resulting in a consistent and even finish, free from sags, runs, or drips. |

| Ease of Maintenance: Epoxy resin powder coatings are easy to clean and maintain. They are less prone to staining, and dirt and contaminants can often be easily removed with regular cleaning. | High Electric Insulation Properties: Epoxy resin coatings have good electrical insulating properties, making them suitable for electrical and electronic applications. |

What is the curing process for epoxy resin powder coating?

- Preparation: Before curing, the coated object should be thoroughly cleaned and prepared to remove any contaminants, oils, or residues from the surface. Surface preparation is crucial to ensure proper adhesion and the desired finish quality.

- Temperature and Time: The curing process is carried out in an oven or curing chamber, where the temperature and time are carefully controlled. The specific curing temperature and duration can vary depending on the epoxy resin powder coating formulation, the size and type of the object being coated, and the desired properties of the final coating.

- Ramp-Up Phase: The curing oven typically has a temperature control system that allows for a gradual ramp-up in temperature. This gradual heating helps prevent defects such as blistering and outgassing. The temperature may be increased at a controlled rate to reach the target curing temperature.

- Soak Time: Once the curing temperature is reached, the coated object is held at that temperature for a specified period known as the "soak time." During this phase, the chemical reactions necessary for cross-linking and curing the epoxy resin take place. The duration of the soak time is critical to ensure complete curing.

- Cooling Phase: After the soak time is completed, the oven temperature is gradually reduced to allow the coated object to cool down. Rapid cooling can lead to stress in the coating, so controlled cooling is essential.

- Verification and Testing: After the object has cooled, it is often subjected to quality control measures and testing to ensure that the epoxy resin powder coating has cured correctly and meets the desired specifications. This may include adhesion tests, hardness tests, and visual inspections.

- Final Inspection: Once the coated object has passed quality control checks, it is ready for final inspection and packaging. The cured epoxy resin powder coating should exhibit the desired appearance, thickness, adhesion, and performance characteristics.

Which industries are epoxy resin powder coatings commonly used in?

| Automotive: Epoxy resin powder coatings are used on automotive components such as wheels, chassis parts, engine components, and suspension parts to provide corrosion resistance and improve aesthetics. | Appliances: Household appliances like refrigerators, washing machines, and ovens often have epoxy resin powder coatings to enhance their appearance and protect against corrosion and wear. |

| Architectural and Construction: Epoxy resin powder coatings are used for architectural finishes on aluminum and steel doors, windows, railings, and other building components. They offer durability, weather resistance, and a range of decorative options. | Electronics: Epoxy resin coatings are used in the electronics industry for components like printed circuit boards (PCBs) and electronic enclosures due to their electrical insulating properties and protection against environmental factors. |

| Industrial Machinery: Many industrial machines and equipment, including pumps, valves, and machinery components, are coated with epoxy resin powder coatings to resist corrosion and extend their service life. | Oil and Gas: Epoxy resin coatings are used on pipelines, tanks, and offshore platforms to protect against corrosion from harsh environmental conditions and exposure to chemicals. |

| Aerospace: In the aerospace industry, epoxy resin powder coatings are used on aircraft components for their lightweight and protective properties. They help improve the durability of aircraft parts. | Marine: Epoxy resin coatings are used on boats, ships, and marine equipment to protect against corrosion and the corrosive effects of seawater. |

| Furniture: In the furniture industry, epoxy resin powder coatings are used to provide a durable and aesthetically pleasing finish on metal furniture frames and components. | Sporting Goods: Items like bicycles, exercise equipment, and outdoor furniture often have epoxy resin powder coatings to enhance their appearance and protect against the elements. |

| Medical Devices: Certain medical equipment and devices are coated with epoxy resin powder coatings for their resistance to chemicals, ease of cleaning, and durability. | Electrical Enclosures: Enclosures for electrical and electronic equipment use epoxy resin powder coatings for electrical insulation and protection against environmental factors. |

| Mining and Construction Equipment: Heavy machinery used in mining and construction, such as bulldozers, excavators, and cranes, often have epoxy resin powder coatings to withstand harsh working conditions. | Infrastructure: Epoxy resin coatings are used for infrastructure projects, including bridges, tunnels, and power transmission towers, to protect against corrosion and weathering. |

What is the curing process for epoxy resin powder coating?

- Preparation: Before curing, the coated object should be thoroughly cleaned and prepared to remove any contaminants, oils, or residues from the surface. Surface preparation is crucial to ensure proper adhesion and the desired finish quality.

- Temperature and Time: The curing process is carried out in an oven or curing chamber, where the temperature and time are carefully controlled. The specific curing temperature and duration can vary depending on the epoxy resin powder coating formulation, the size and type of the object being coated, and the desired properties of the final coating.

- Ramp-Up Phase: The curing oven typically has a temperature control system that allows for a gradual ramp-up in temperature. This gradual heating helps prevent defects such as blistering and outgassing. The temperature may be increased at a controlled rate to reach the target curing temperature.

- Soak Time: Once the curing temperature is reached, the coated object is held at that temperature for a specified period known as the "soak time." During this phase, the chemical reactions necessary for cross-linking and curing the epoxy resin take place. The duration of the soak time is critical to ensure complete curing.

- Cooling Phase: After the soak time is completed, the oven temperature is gradually reduced to allow the coated object to cool down. Rapid cooling can lead to stress in the coating, so controlled cooling is essential.

- Verification and Testing: After the object has cooled, it is often subjected to quality control measures and testing to ensure that the epoxy resin powder coating has cured correctly and meets the desired specifications. This may include adhesion tests, hardness tests, and visual inspections.

- Final Inspection: Once the coated object has passed quality control checks, it is ready for final inspection and packaging. The cured epoxy resin powder coating should exhibit the desired appearance, thickness, adhesion, and performance characteristics.

Have Anything To Ask Us?