Powder coating pinholes: Causes and Solutions

Table of Contents

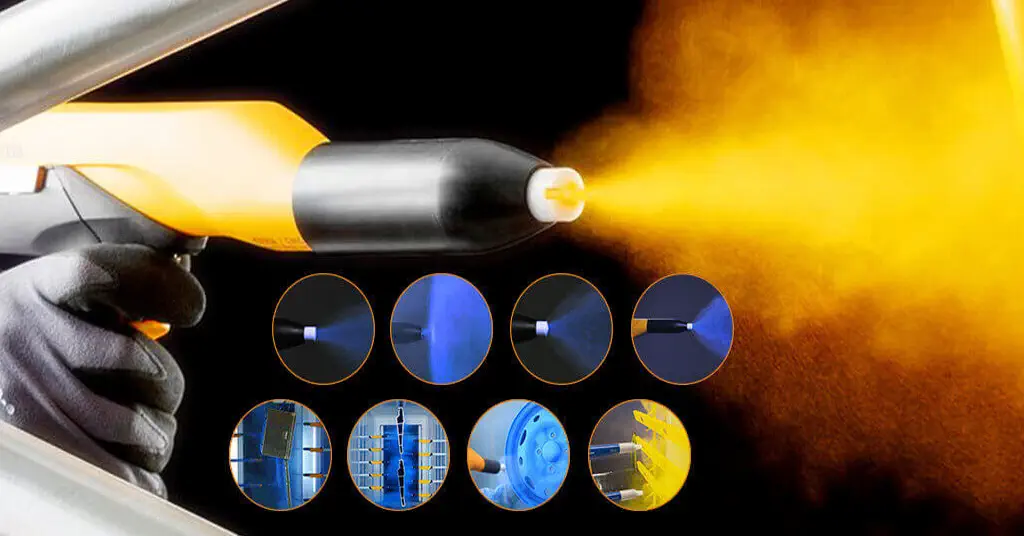

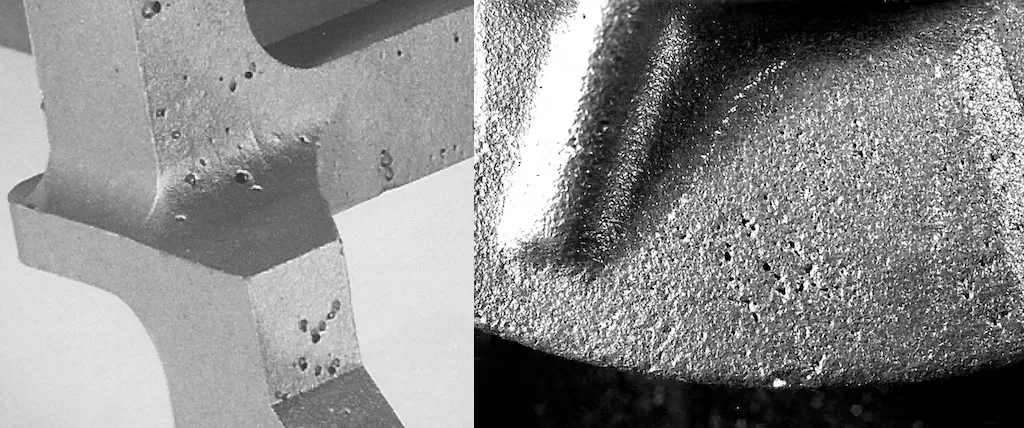

After powder coating is sprayed, it accumulates in a loose structure on the workpiece. This loose structure causes a large number of gaps between powder particles to be filled by air. As the ambient temperature increases, the powder coating particles melt, causing this loose structure to collapse. Due to the thickness of the powder coating film generally exceeding 50 μ The loose structure after spraying is much larger than this thickness. The powder particles in the middle position that heat up slowly melt slower, causing the air between their particles to be trapped by the molten coating. As the curing process progresses, the viscosity of the system gradually increases, and the air trapped in the coating leads to the formation of coating pinholes.

This type of coating pinhole is inevitable for thermosetting powder coatings due to their own characteristics. Therefore, strictly speaking, pinholes are the inherent defects of powder coatings. In order to eliminate the above-mentioned factors that lead to primary pinholes, a degassing agent is a necessary raw material in the formulation of high gloss powder coatings, and benzoin is an efficient degassing agent for eliminating the aforementioned pinholes. The defoaming mechanism of benzoin is very complex. In addition to eliminating the above-mentioned pinholes, benzoin also has a certain effect on eliminating pinholes caused by other factors.

1. Volatile small molecules generated by the curing reaction of powder coatings

The curing reaction of powder coatings can be divided into two types. One type is the direct reaction without small molecule release, such as the reaction between carboxyl and epoxy groups, and the reaction between hydroxyl and unsealed isocyanate groups. At present, the widely used polyester/epoxy hybrid indoor powder coatings, polyester/TGIC outdoor powder coatings, GMA acrylic resin/DDDA transparent powder coatings, pure epoxy powder coatings, etc. in the market do not produce additional small molecules during the curing process.

Another type of curing reaction releases small molecules, such as polyester/ β- Hydroxyalkylamide outdoor powder coatings, hydroxypolyester/tetramethoxymethyl glycylurea powder coatings, and hydroxy/blocked isocyanate powder coating systems release water, methanol, and isocyanate sealants during the curing process. The small molecules released by the solidification reaction aggregate into bubbles and are discharged from the coating. However, due to the increase in viscosity of the powder system and the problem of film thickness, some small molecules are not released in time and are trapped inside the coating, resulting in the formation of pinholes. Therefore, this type of powder coating not only needs to solve the original pinholes, but also needs to eliminate the additional small molecule bubbles that are generated and aggregated.

Practice has shown that benzoin alone cannot significantly solve this pinhole problem. The elimination of pinholes in such powder coatings requires not only the use of benzoin, but also the use of other defoaming and degassing agents.

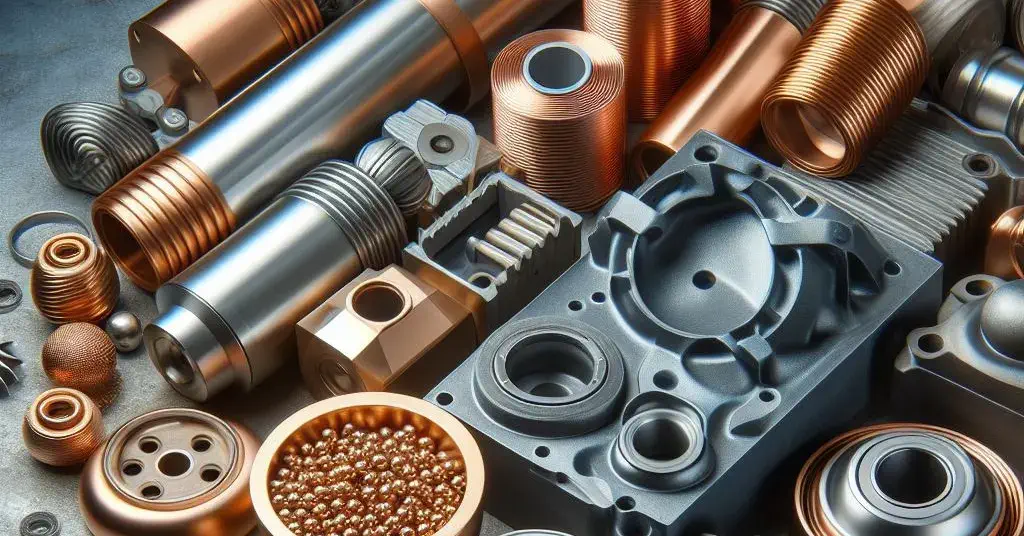

2. Factors of the workpiece substrate itself

The workpiece substrate is another important cause of pinholes in powder coating films, and porous substrates such as cast aluminum and cast iron are high incidence areas for pinhole problems in powder coatings. The reason for this is that the porous substrate itself contains a large amount of air, or there is a large amount of volatile substances (such as undeveloped moisture) in the gaps. After powder coating is completed, the air or volatile substances in the gaps are sealed by the melted powder coating during the heating process. As the coating solidifies, the viscosity of the system increases rapidly, making it difficult for the gas in the gaps to be released from the coating, resulting in pinholes.

How to eliminate the problem of pinholes in such powder coatings? Firstly, before spraying, the porous substrate can be preheated at a higher temperature and for a longer period of time, and the substrate can be dried as much as possible, so that the powder coating has a lower initial melting viscosity due to the high substrate temperature, which helps to expel gas from the substrate. In the production of powder coatings, on the one hand, certain substances that can improve the wettability of the powder coating substrate can be added to the powder coating formula, so that the molten coating can quickly penetrate into the porous substrate and expel the gas in the gaps as early as possible when the initial melting viscosity of the system is low. On the other hand, resins with lower melt viscosity (film-forming substances) should be selected, or certain substances that can significantly reduce the melt viscosity of coatings should be added to the powder formulation.

In order to improve the wetting performance of powder coatings on substrates, certain compounds containing polar groups (such as amide groups, hydroxyl groups, etc.) can be added to the system. These compounds not only help to wet the substrate, but also help reduce the melting viscosity of the system, similar to solvents or diluents in liquid coatings. Due to their solid nature in powder coatings, they can be referred to as “solid solvents”.

3. Wet powder coating

Unless the conditions are exceptionally harsh, powder coatings are not easily affected by moisture under normal circumstances. The tendency for powder to become damp is often due to the powder being stored in low-temperature conditions for a long time and suddenly entering a high-temperature and humid environment. The powder coating after unboxing is prone to moisture condensation in the air due to the lower temperature.

After severe moisture exposure, a large amount of moisture is introduced into the powder coating system, which is discharged from the coating during the baking process. Some of the gas that cannot be discharged in time is expressed in the form of very small pinholes, usually in the form of mist shadows.

This type of problem can only be prevented. Firstly, it is important to ensure normal storage conditions for the powder, and secondly, to avoid ultra-low temperature storage as much as possible. If low-temperature storage is necessary, sufficient time should be allowed for the powder to return to normal temperature before opening the box for use to avoid moisture.

4. Selection of defoamers

Benzoin is the most effective defoaming and degassing agent for high gloss powder coatings, which can effectively eliminate normal film thickness (60-90 μ) Primary pinholes below. Benzoin also has a certain synergistic effect on pinholes caused by other reasons, but its effect is often limited. Excessive use of benzoin can also cause yellowing of the coating, and benzoin itself is a substance that is easily decomposed by heating. Excessive use can have negative effects.

Defoamers containing amide and hydroxyl groups can effectively improve the wetting performance of coatings on substrates, as well as improve the wetting properties of resins on pigments, especially inorganic fillers, reducing the melting viscosity of coatings and effectively eliminating bubbles caused by various reasons. Of course, it is also necessary to choose a resin with low viscosity and gelation time to prevent serious bubble formation.

Transparent powder defoamer: As a special type of powder coating, the principle and defoaming method of producing pinholes in transparent powder are the same as ordinary powder coatings. A special point is that transparent powder is a highly transparent system, and the entire system is optically isotropic without severe phase separation. Therefore, during the defoaming process, the defoaming and degassing agent added must be completely compatible with the system. In this sense, such defoamers need to be carefully selected.

Conclusion

In general, the formation of bubbles in powder coatings is caused by various factors. The pinholes in powder coatings are mainly formed by the increase of system viscosity during the curing process, which leads to the inability of small molecule gases trapped in the coating to be discharged in a timely manner. Therefore, selecting appropriate defoamers and paying attention to the storage and use conditions of coatings can effectively improve the effectiveness of coatings.

Erik

Doctor of Chemical Engineering, expert in the field of powder coatings, with over 20 years of professional experience in the research and application of powder coatings

Have Anything To Ask Us?